Intelligent extract method of edge temperature of blast furnace charge level temperature field

A blast furnace material surface and extraction method technology, which is applied to blast furnaces, thermometers, blast furnace details, etc., can solve problems such as difficult to obtain accurate temperature information at the edge of the material surface temperature field, and achieve the effect of smooth production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

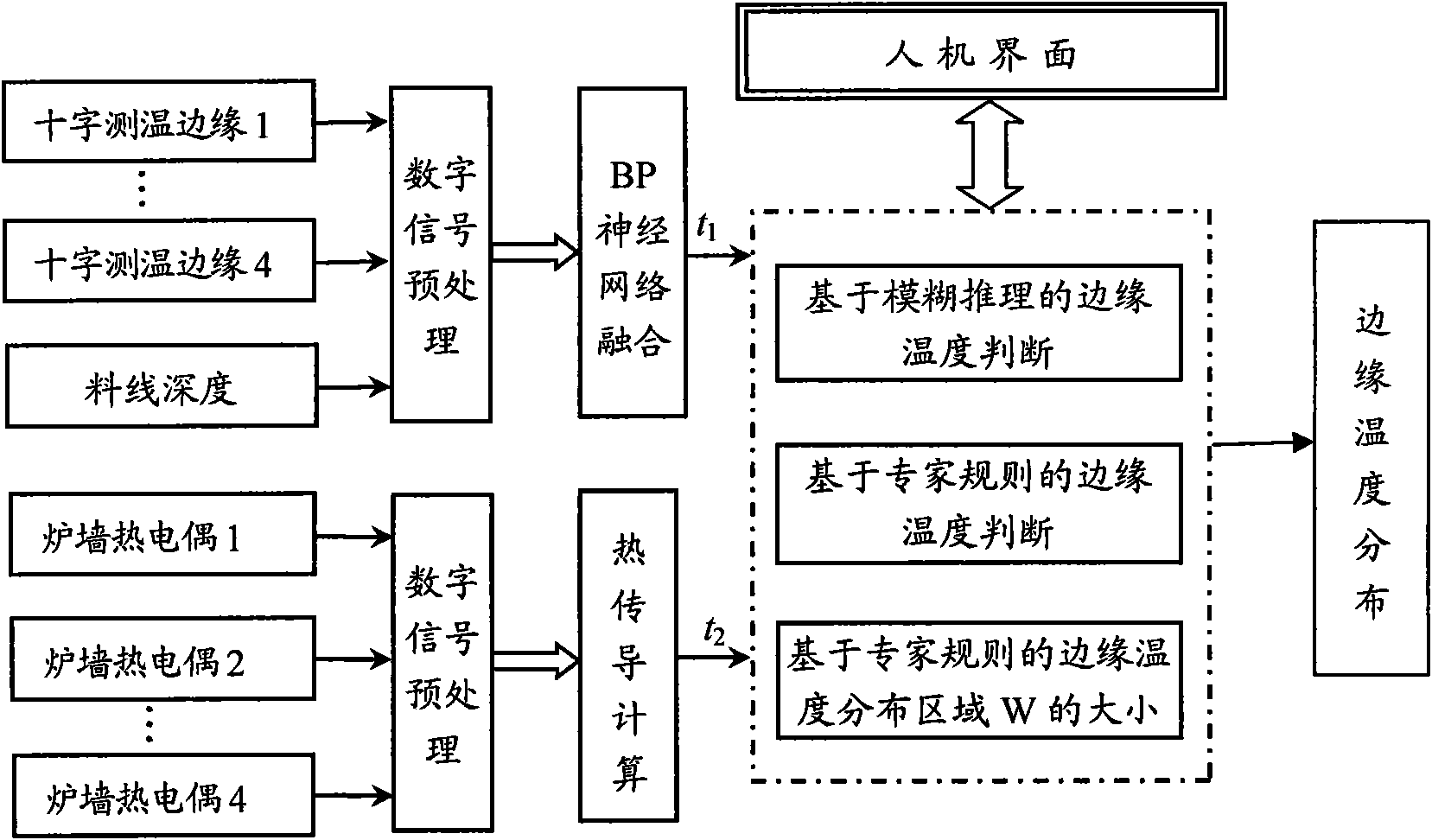

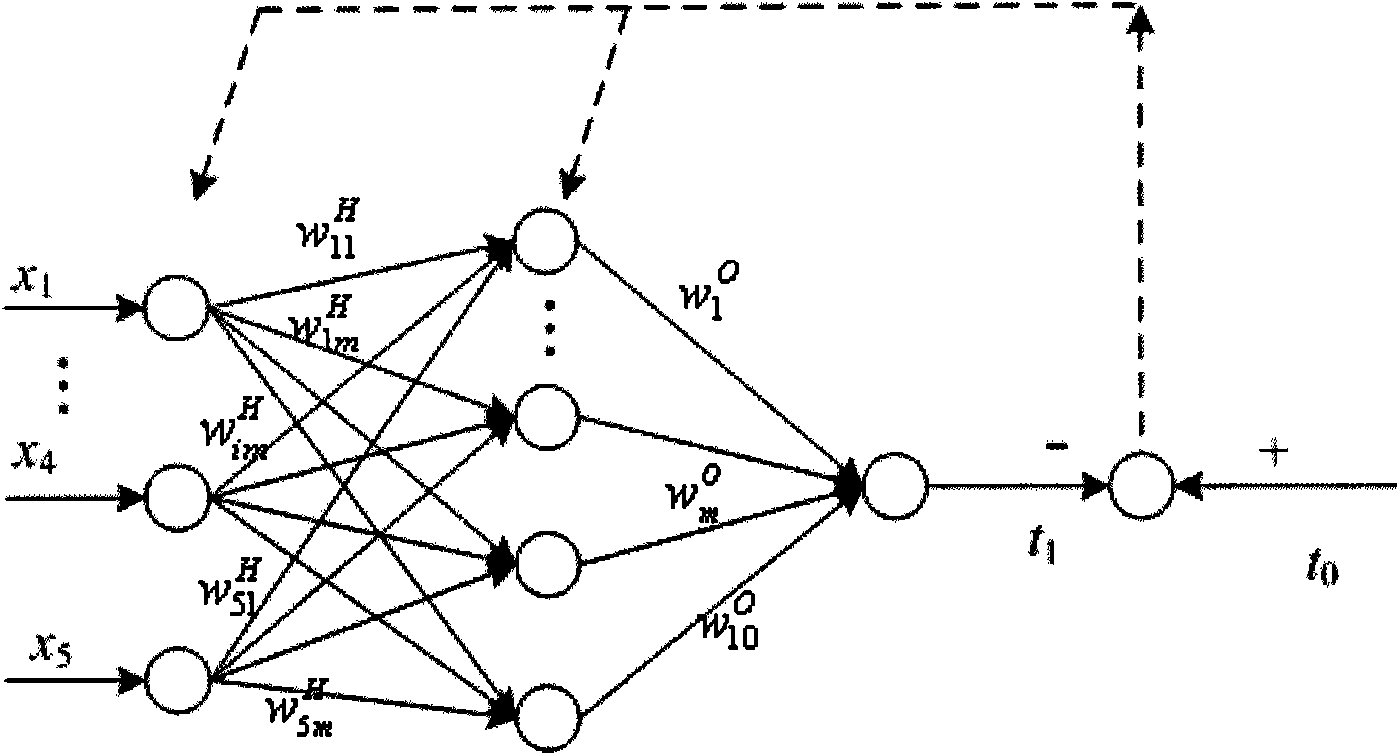

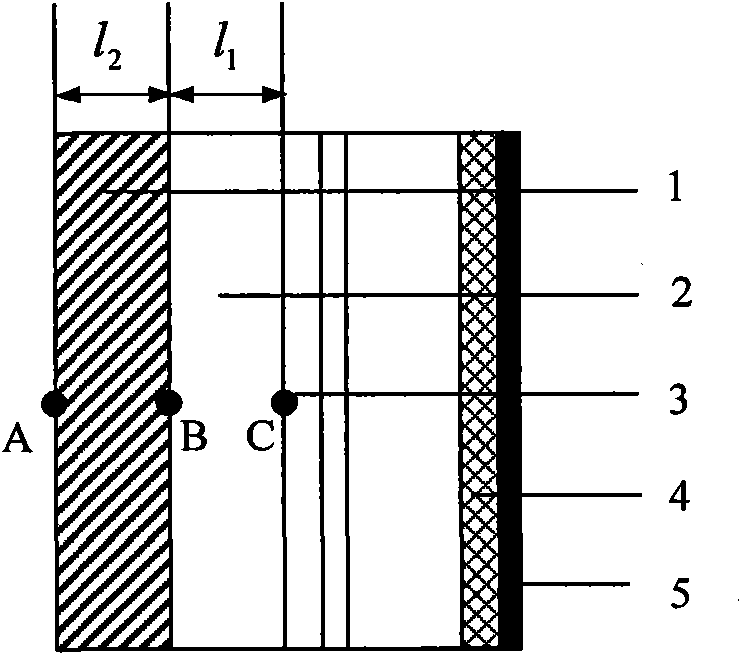

[0024] For more than 2000m 3 In the large-scale blast furnace, the invention uses the temperature information of the furnace wall thermocouple, combines the heat conduction theory to calculate the gas temperature inside the furnace wall, and adopts fusion methods such as neural network, fuzzy reasoning and expert rules to integrate the edge temperature of the cross temperature measurement and the depth of the material line, etc. Multi-source detection information realizes the soft measurement of the edge temperature of the blast furnace material surface temperature field.

[0025] (1) Edge temperature calculation based on cross temperature measurement

[0026] Since the digital signal obtained from the temperature information obtained from the cross temperature measuring thermocouple after corresponding transformation contains noise components introduced from various noise sources, it is first necessary to perform digital signal preprocessing on the collected data, mainly refe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com