Patents

Literature

38results about How to "Reduce residual oxygen" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

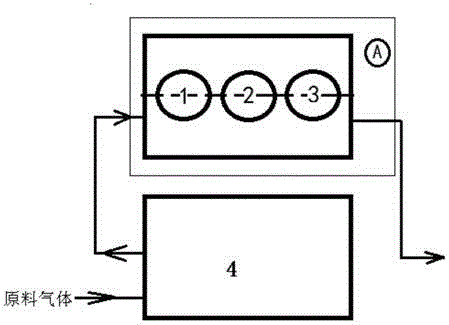

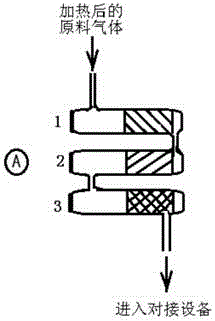

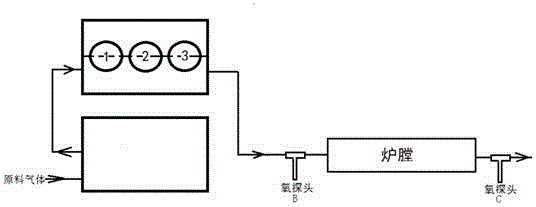

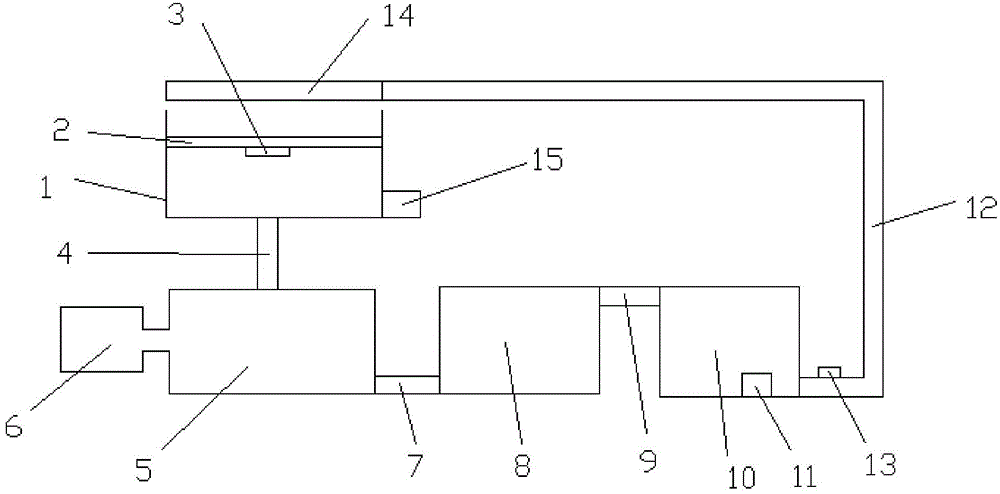

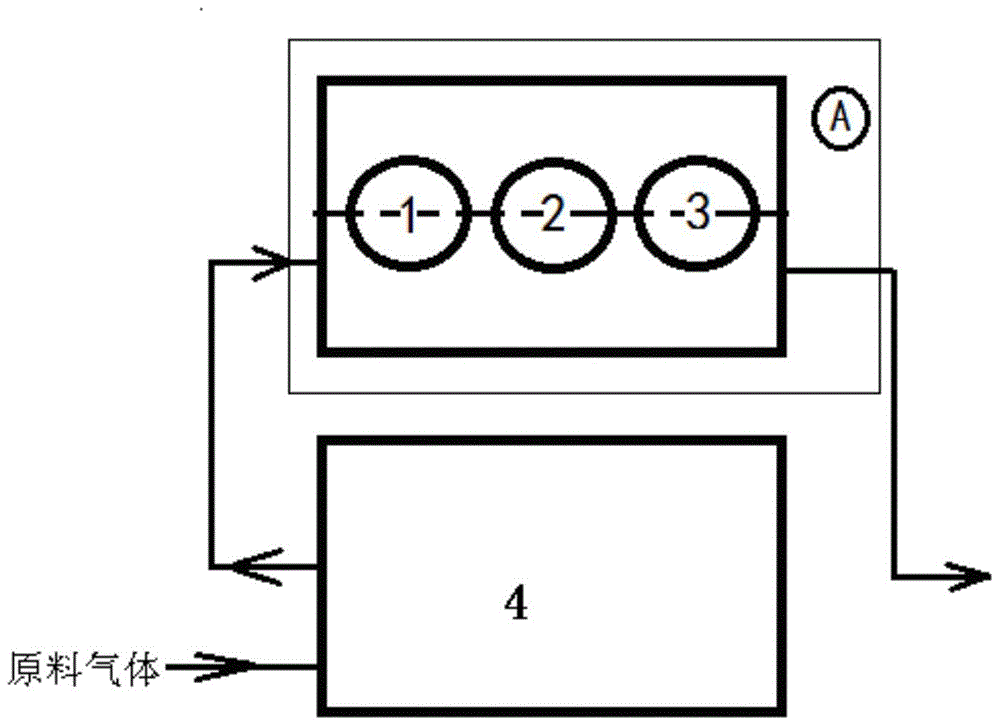

Deep deoxidizing apparatus and application thereof

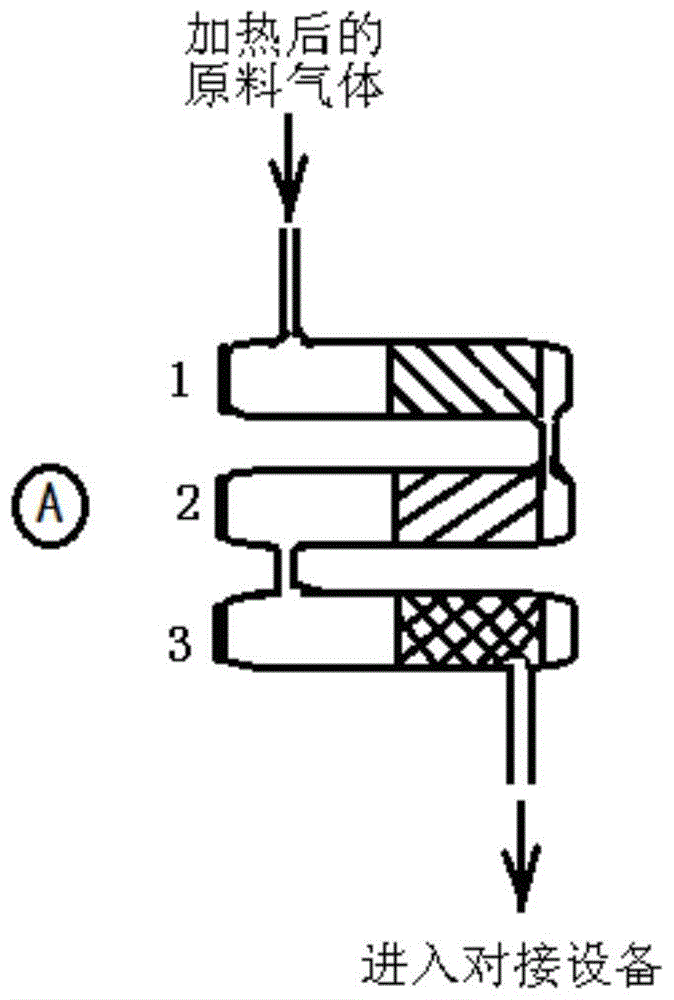

The invention relates to a deep deoxidizing apparatus and an application thereof, and belongs to the technical field of chemical reaction deoxidization. The deep deoxidizing apparatus designed by the invention comprises a gas heating device (4), a No.1 deoxidizing channel (1), a No.2 deoxidizing channel (2) and a No.3 deoxidizing channel (3) which are sequentially communicated, wherein a No.1 deoxidizing agent is contained inside the No.1 deoxidizing passage (1), and the No.1 deoxidizing agent is selected from one of elemental metallic copper and copper-based alloy; a No.2 deoxidizing agent is contained inside the No.2 deoxidizing channel (2), and the No.2 deoxidizing agent is selected from one of elemental metallic titanium, sponge titanium and titanium-based alloy; a No.3 deoxidizing agent is contained inside the No.3 deoxidizing passage (3), and the No.3 deoxidizing agent is selected from one of elemental magnesium and magnesium-based alloy. The apparatus disclosed by the invention, when applied to deoxidizing treatment on Ar gas which is 99.999% in purity, can achieve a deoxidizing precision of 10-21ppm. The apparatus designed by the invention can carry out efficient deep deoxidization under normal pressure, and has the advantages of simple equipment, recycling use of the deoxidizing agents and the like.

Owner:CENT SOUTH UNIV

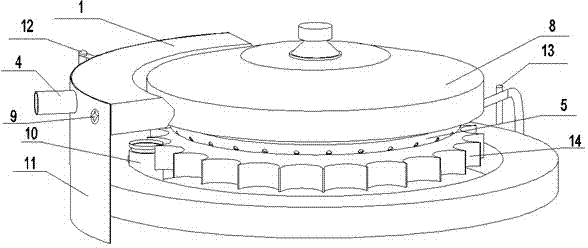

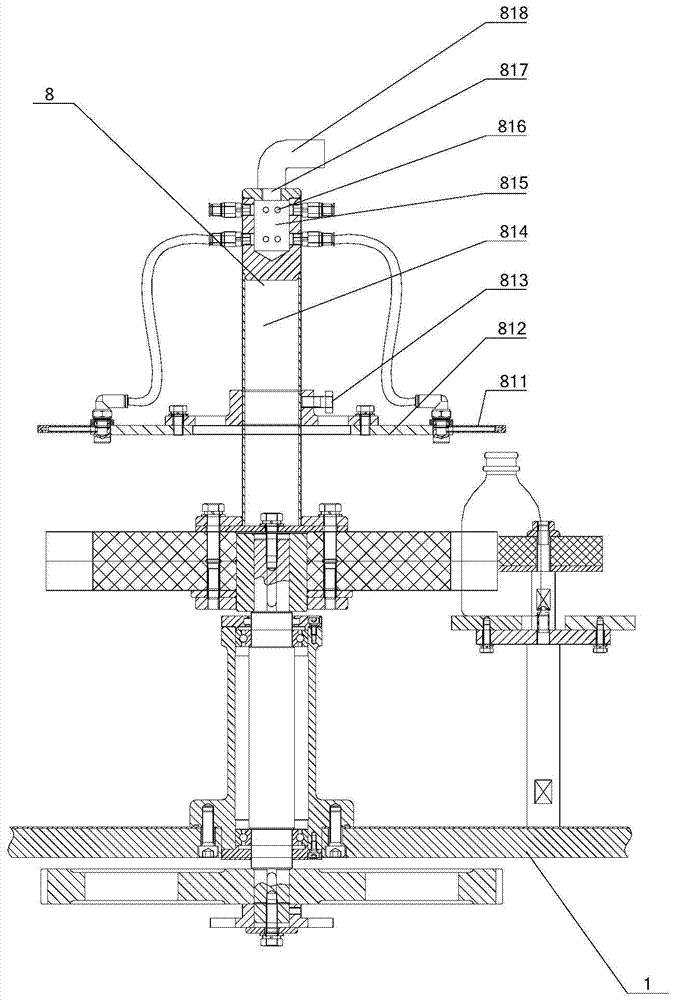

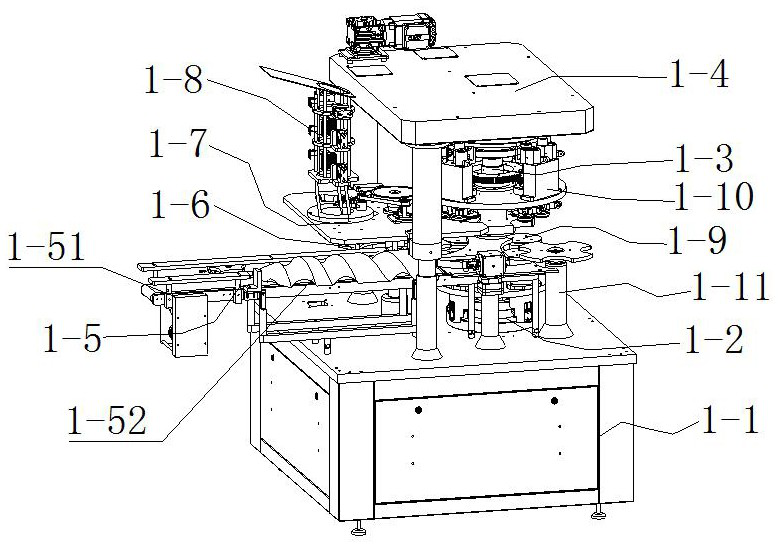

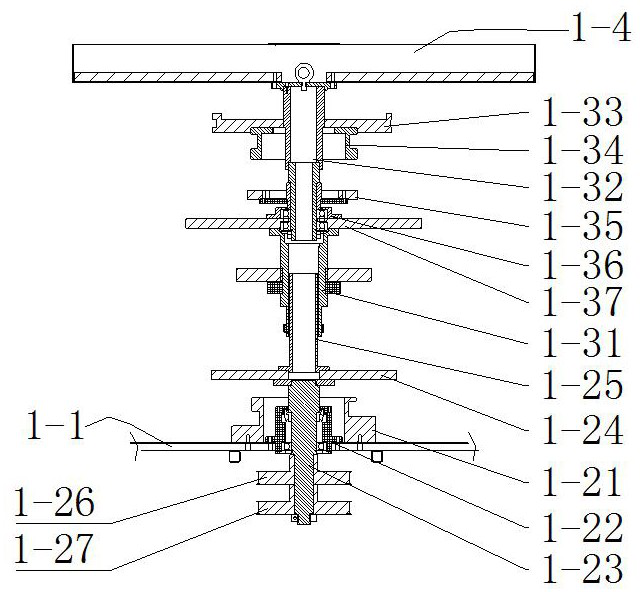

Racking machine with nitrogen charging device

ActiveCN104260923AImprove Nitrogen Filling EfficiencyNitrogen filling time is shortPackaging by pressurising/gasifyingNitrogen sourceEngineering

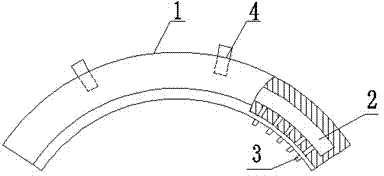

The invention discloses a racking machine with a nitrogen charging device. The racking machine is applied to pharmacy workshops and comprises a rotary capping machine and the nitrogen charging device corresponding to the rotary capping machine. The nitrogen charging device comprises an arc nitrogen seal part and a nitrogen charging semicircular ring, the arc nitrogen seal part is internally provided with a gas chamber communicated with two gas inlets I connected with a nitrogen source, the arc nitrogen seal part is uniformly provided with a plurality of gas outlets I communicated with the gas chamber, and a retaining curtain is arranged on an outer arc face of the arc nitrogen seal part; the nitrogen charging semicircular ring comprises a semicircular ring bent pipe section and a straight pipe section, the outer arc face of the semicircular ring bent pipe section is uniformly provided with a plurality of gas outlets II, and the nitrogen charging semicircular ring is communicated with the nitrogen source through a gas inlet I on the straight pipe section. Nitrogen is filled into bottles by two nitrogen charging systems, so that nitrogen charging efficiency is higher and nitrogen charging time is shorter; owing to the retaining curtain, remaining oxygen content in penicillin bottles is effectively reduced to less than one percent, and accordingly medicine storage time is prolonged.

Owner:NORTH CHINA PHARMA HEBEI HUAMIN PHARMA

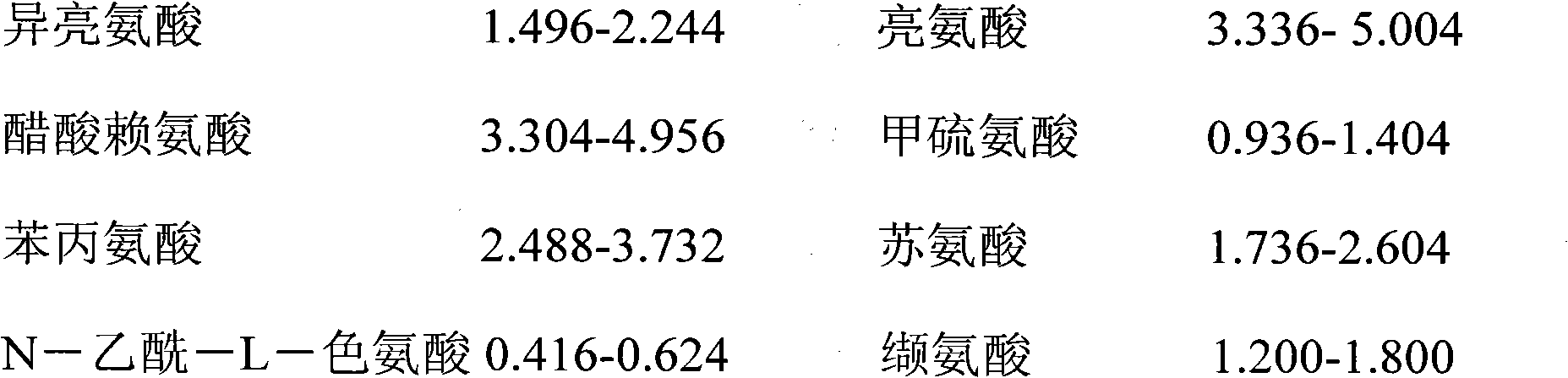

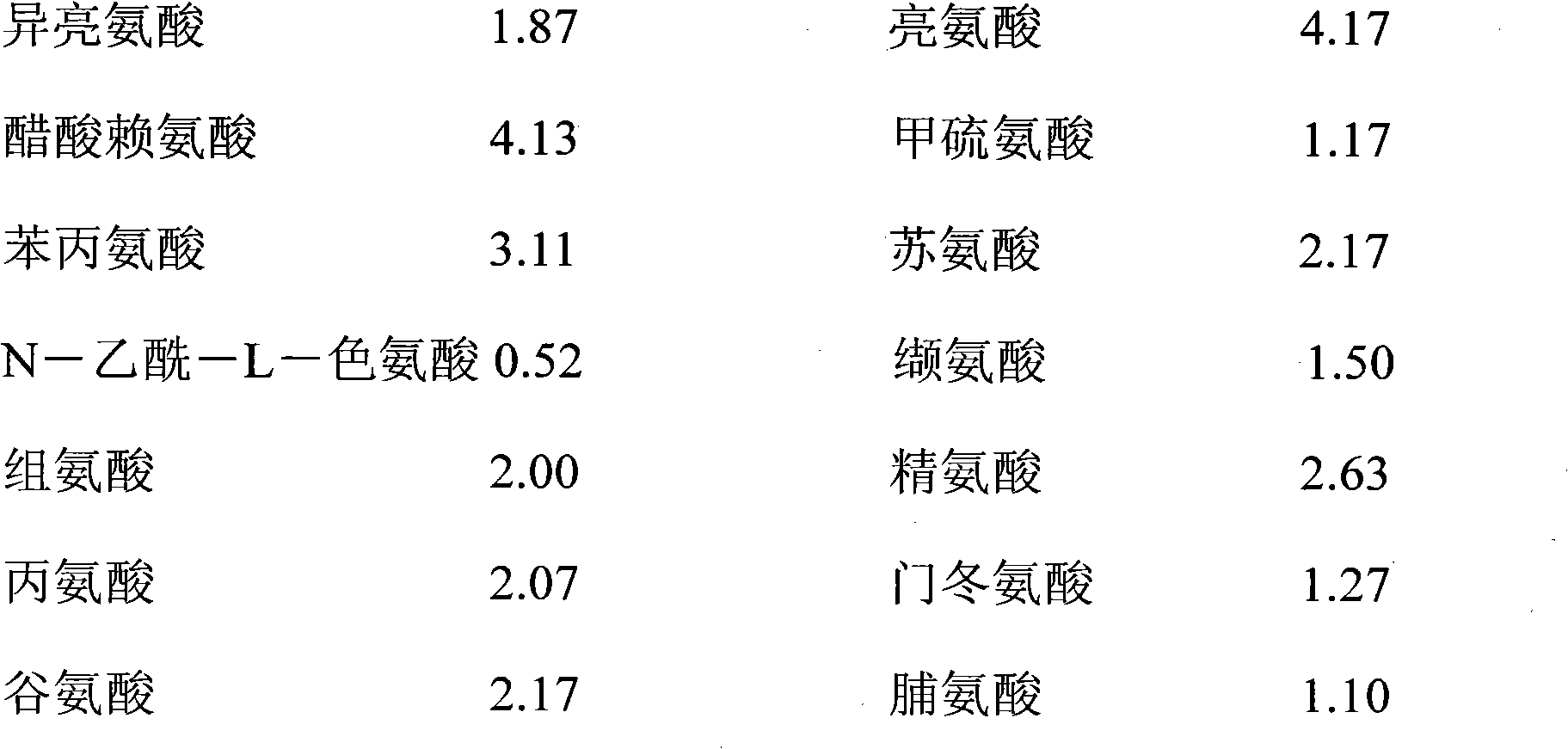

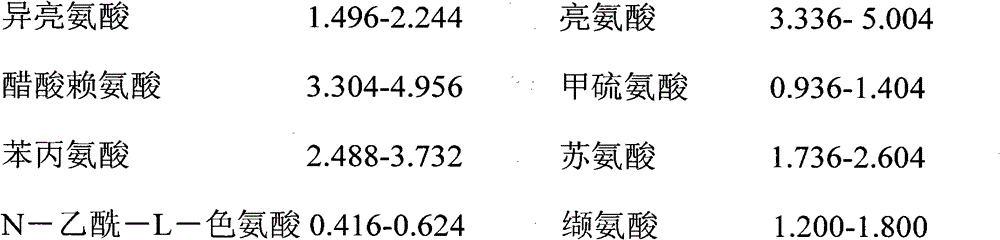

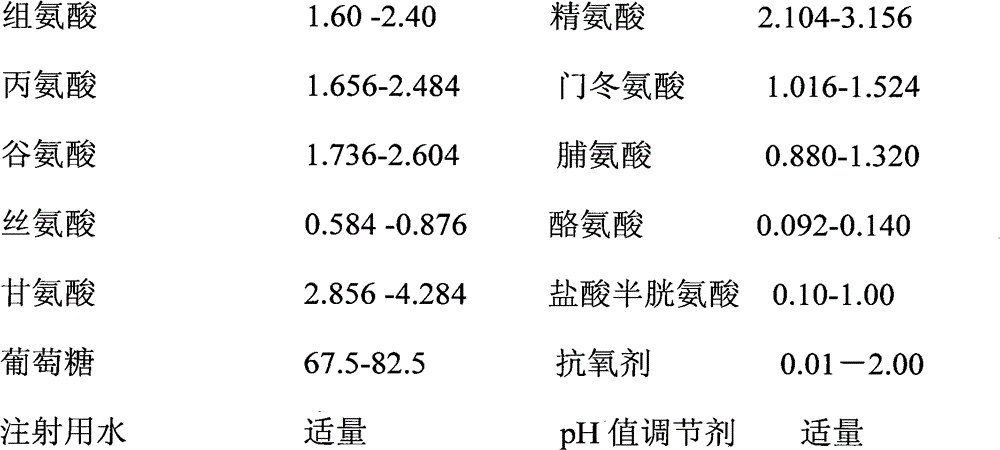

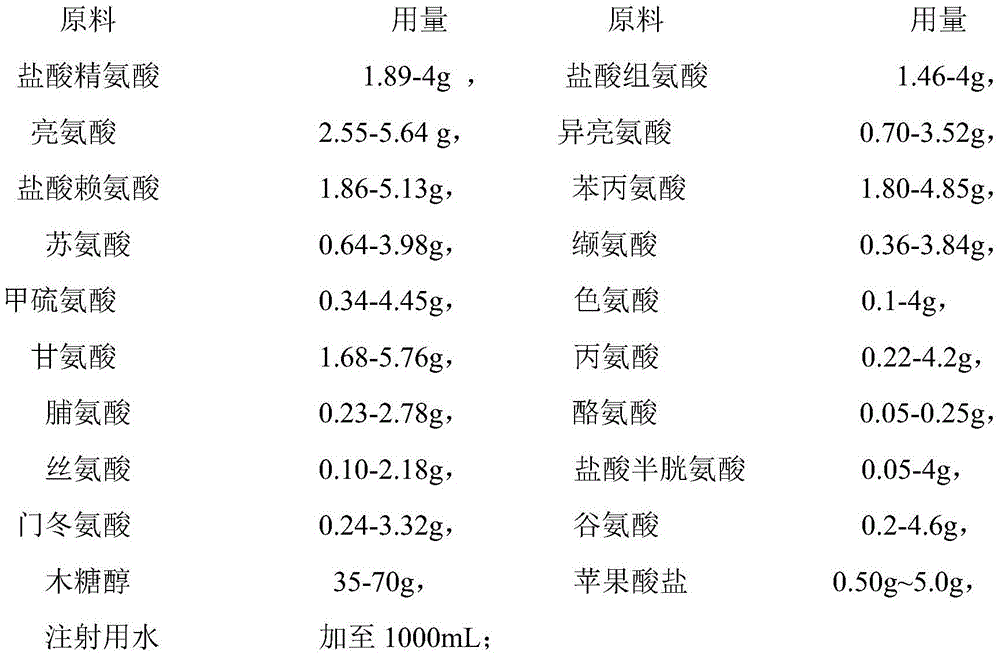

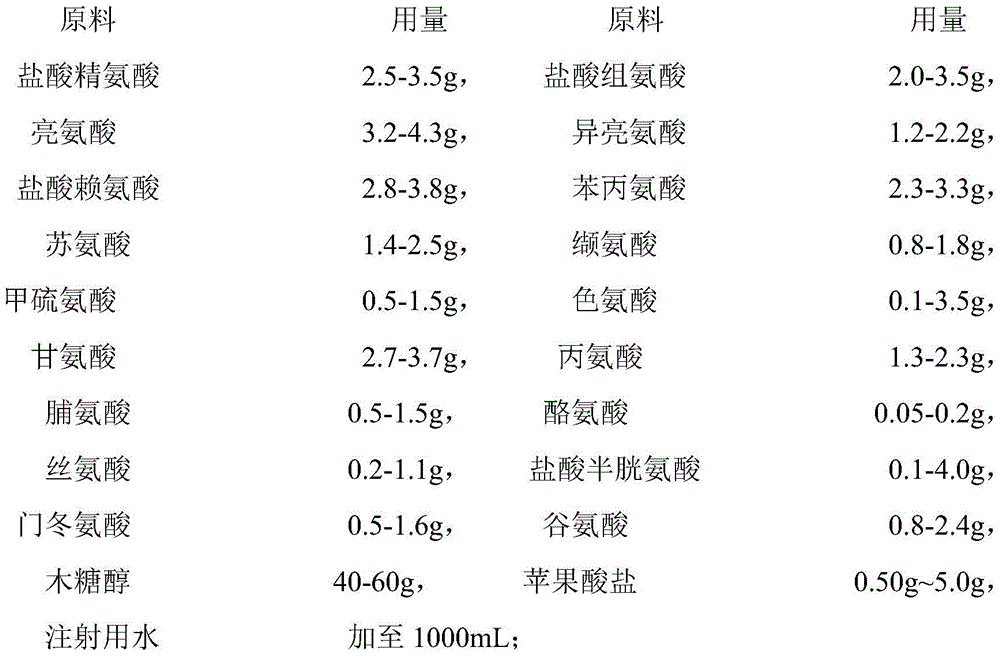

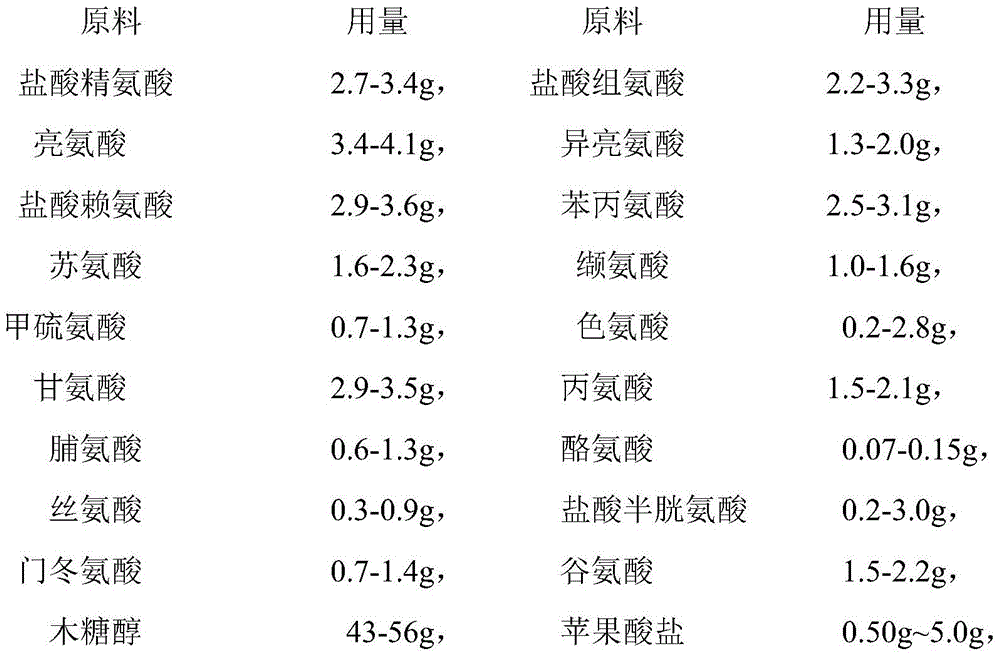

Pharmaceutical composition containing 18 amino acids

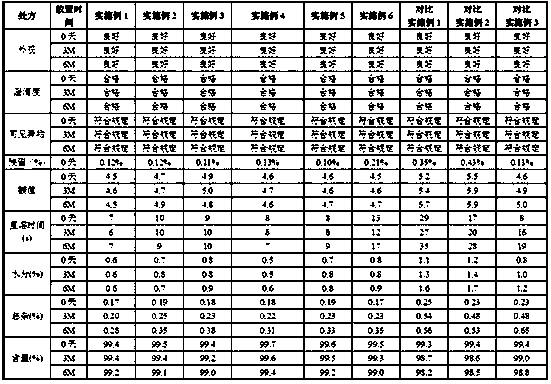

InactiveCN102626409AReduce residual oxygenAvoid huge investment in transformationOrganic active ingredientsPeptide/protein ingredientsSAFERAntioxidant

The invention discloses a pharmaceutical composition containing 18 amino acids. The pharmaceutical composition containing 18 amino acids is characterized in that raw materials of 18 amino acids and auxiliary materials of an antioxidant and a pH conditioning agent are prepared into compound amino acid injections (18AA-IV) having different concentrations, wherein the compound amino acid injection is the pharmaceutical composition containing 18 amino acids and has a pH value of 3.5 to 5.5. The pharmaceutical composition containing 18 amino acids does not contain a sulfite antioxidant and thoroughly prevents the damage of sulfites on the human body. Products of the pharmaceutical composition containing 18 amino acids are safer in clinical use. An accelerated stability test proves that the pharmaceutical composition (18AA-IV) containing 18 amino acids has the stability the same as or superior to the stability of commercial sulfite-containing like products.

Owner:郑飞雄

Formed product

ActiveUS20110210034A1Excellent oxygen barrier propertiesSuppresses deterioration of oxygen barrier propertySynthetic resin layered productsSacksPolymer scienceChemical compound

The formed product of the present invention is a formed product selected from the group consisting of a vertical form fill seal pouch, a container cover and a vacuum packaging pouch. The formed product is formed using a gas barrier layered product. The gas barrier layered product includes a base, and at least one layer with gas barrier properties that is stacked on the base. The layer is formed of a composition that includes a hydrolyzed condensate of a compound (L) and a neutralized product of a polymer (X) containing a carboxyl group or a carboxylic acid anhydride group. The compound (L) includes a compound (A) that contains M1 (Al, Ti or Zr) to which a hydrolyzable characteristic group is bonded and a compound (B) that contains Si to which a hydrolyzable characteristic group is bonded. At least part of —COO— group of the polymer (X) is neutralized with a metal ion having a valence of at least two. At least 80 mol % of the compound (B) is a compound expressed by a specific formula. The ratio of [the number of moles of M1 in the compound (A)] / [the number of moles Si in the compound (B)] is in the range of 0.1 / 99.9 to 35.0 / 65.0.

Owner:KURARAY CO LTD

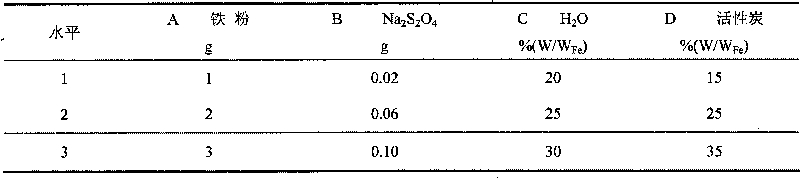

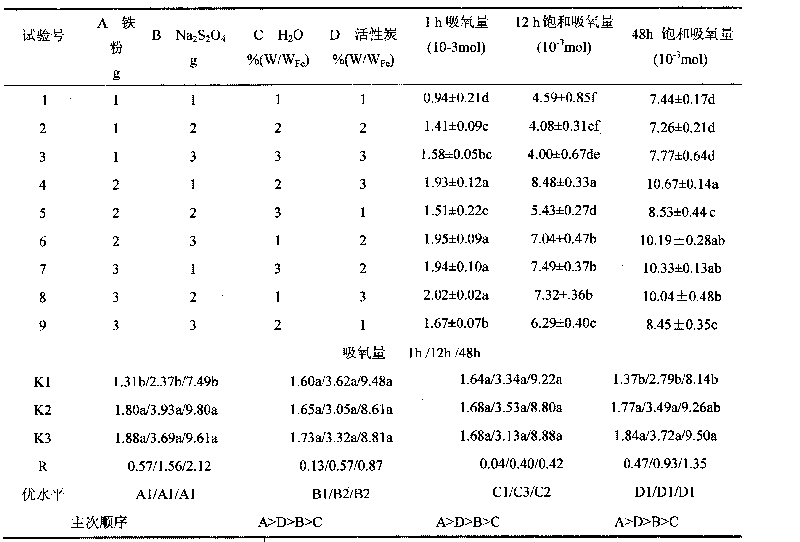

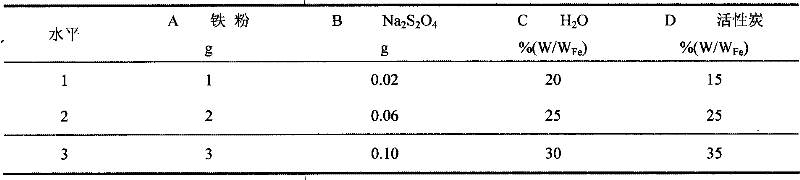

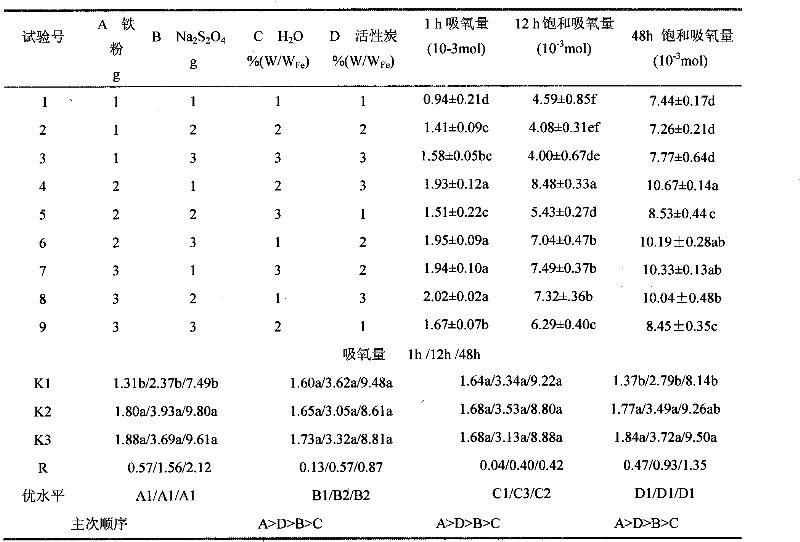

Mixed type special deoxidizer for ham and preparation method

InactiveCN101700053AGuaranteed oxygen removal effectImprove short-term rapid deoxygenation speedMeat/fish preservation using chemicalsActivated carbonFood packaging

The invention relates to a mixed type special deoxidizer for a ham and a preparation method, belonging to the field of food packaging. The special deoxidizer is prepared by adopting fast acting chalcogenide deoxidizer and slow acting iron-based deoxidizer, and comprises the following components according to following proportioning 2.10-2.70 parts of Fe, 0.25-0.35 part of activated carbon, 0.06-0.08 part of Na2S2O4, 15-25 percent of H2O (w / wFe), 5-10 percent of NaCl and 25-35 percent of Ca (OH)2 (w / wNa2S2O4). The special deoxidizer for ham prepared by mixing can fast remove residual oxygen in vacuum package, can absorb penetrative oxygen of the package for a long time, efficiently prevent the fast oxidation and browning of section of the ham, continuously and stably absorb the oxygen within 12h, maintain certain oxygen absorption ability for a long time, satisfy the requirements of special antioxidation package of the prior cutout ham and prolong the storage period of the ham.

Owner:南京扬乾生物科技有限公司

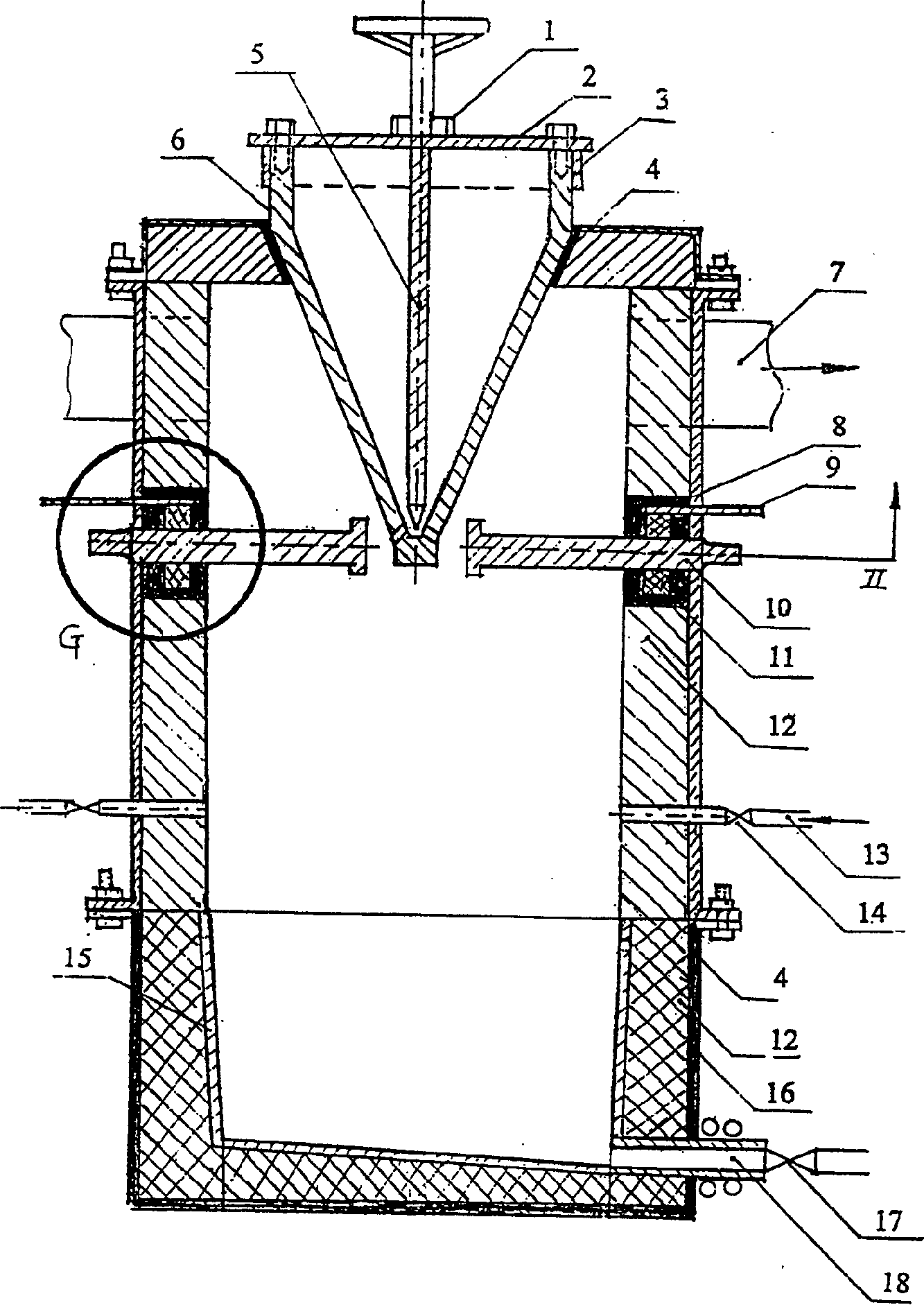

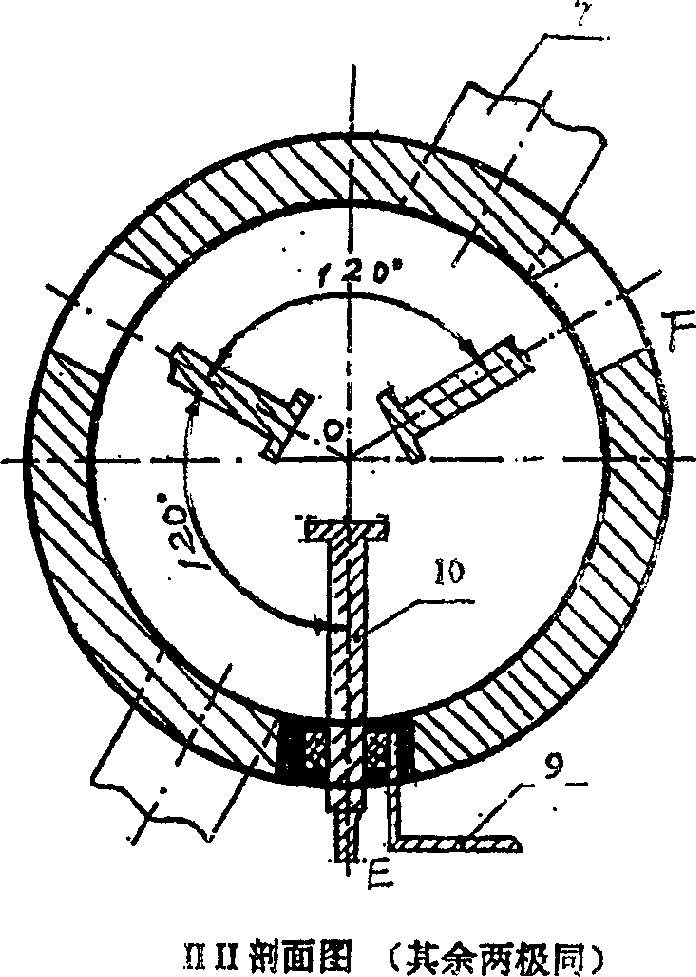

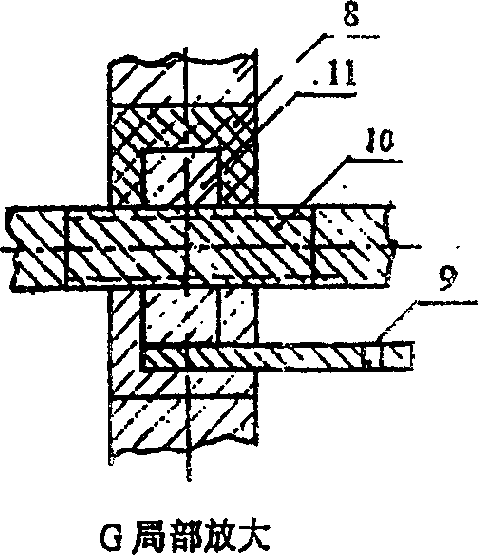

Device and method for producing medium and low melting point metals and oxide nitride powder

The present invention is apparatus and method for producing medium and low melting point metals and their oxide or nitride powder, and belongs to the field of interdisciplinary powder metallurgy and machine building technology. The present invention produces metal or alloy powder of melting point in 185-899 deg C in a triphase AC arc vaporizing apparatus, and the triphase AC arc vaporizing process after opening the conic valve is one process including the steps of forming reciprocating liquid flow bridge of molten metal among three electrodes, neck reducing, arcing, breaking liquid flow bridge to vaporize metal and re-forming liquid flow bridge. The present invention has the advantages of high production speed, high product quality, fine powder granularity, low power consumption, etc.

Owner:KUNMING UNIV OF SCI & TECH

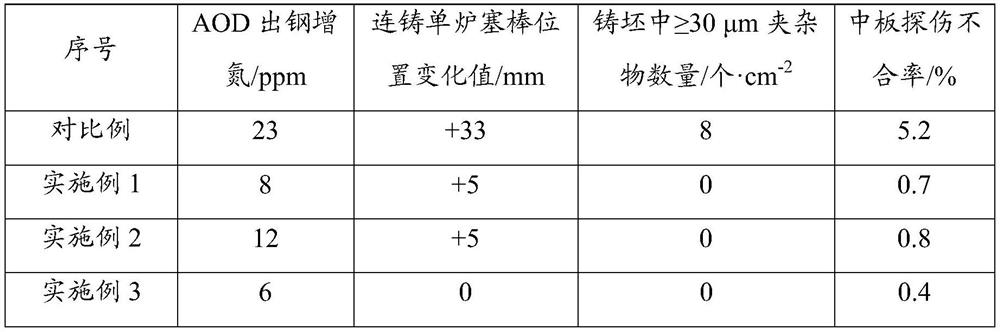

Control method for inclusions in high-titanium steel, high-titanium steel and preparation method of high-titanium steel

ActiveCN114381574AReduce burning loss and oxidationHigh yieldProcess efficiency improvementSlagTitanium

The invention belongs to the technical field of iron and steel smelting, and relates to a control method of high-titanium steel inclusions, high-titanium steel and a preparation method of the high-titanium steel. The control method for the high-titanium steel inclusions comprises the steps that (1) after AOD blowing is finished, silicon-aluminum composite deoxidation is adopted; (2) aluminum shots, lime and fluorite are added into the molten steel after slagging-off, and argon is blown from the bottom for stirring; (3) titanium alloy blocks are added for titanium alloying, the adding amount of the titanium alloy blocks is calculated according to the yield of 65-80%, and argon bottom blowing continues after titanium alloying; (4) tapping and keeping argon oxygen decarburization (AOD) bottom blowing argon; and (5) after the component temperature of the molten steel and the components of the slag are adjusted through the LF, pure calcium wires or silicon-calcium blocks are fed. According to the control method for the high-titanium steel inclusions, the defects of nozzle nodulation, 'fish formation 'of a continuous casting crystallizer and inclusion on the surface of a product or failure in flaw detection caused by precipitation of a large amount of TiN are overcome.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

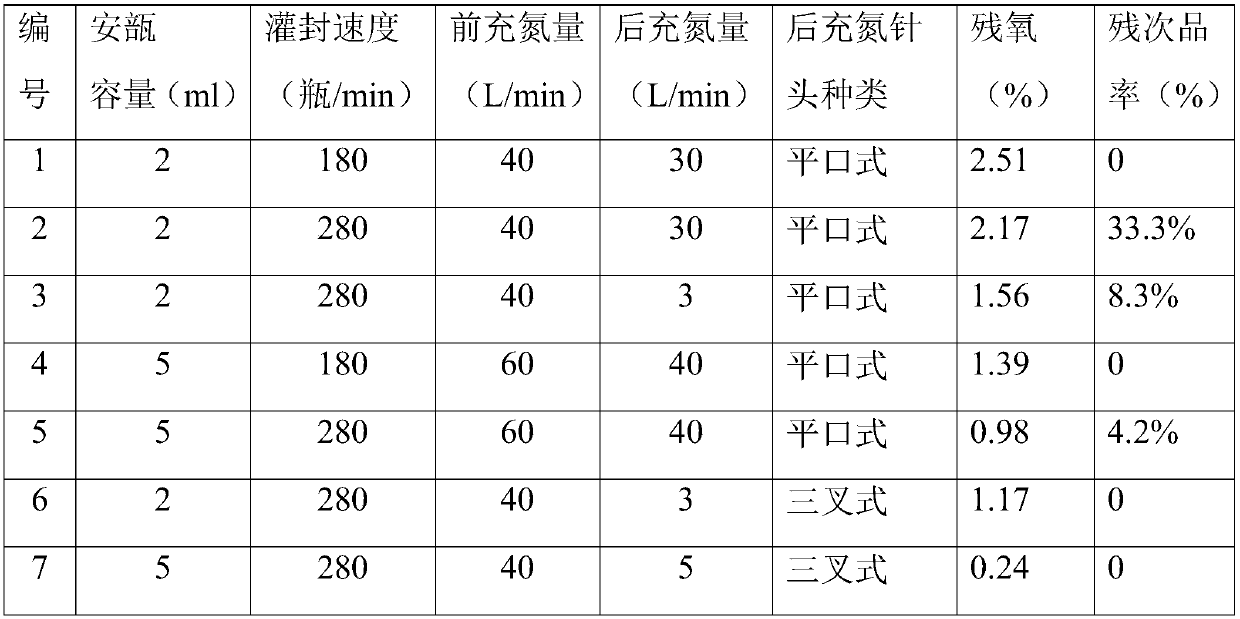

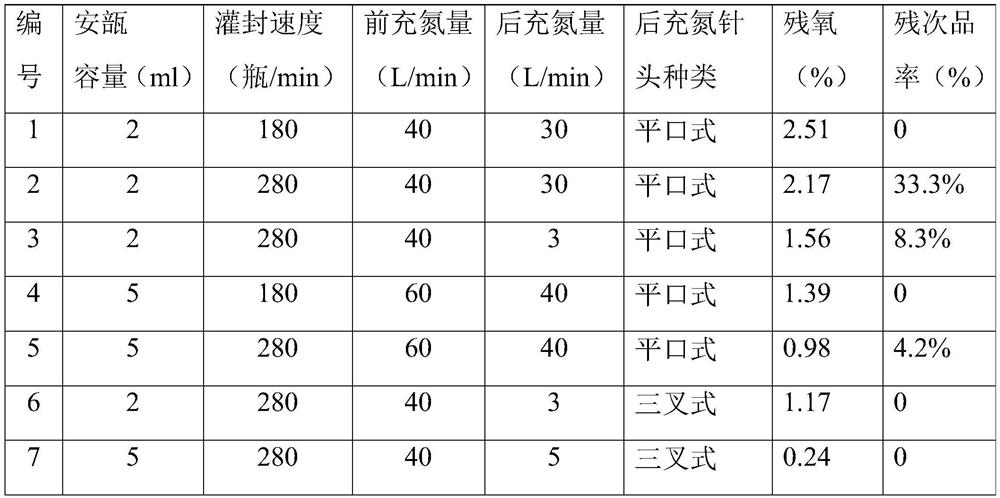

Method for controlling amount of residual oxygen in packages for medicine filling

ActiveCN111204487AReduce residual oxygenImprove oxidation stabilityPackaging by pressurising/gasifyingMedicineProcess engineering

The invention belongs to the field of medicine packages, and discloses a method for controlling the amount of residual oxygen at the top of an ampoule or a vial filled with pharmaceutical preparationand a production method of a filled finished product obtained by filling the ampoule or vial with the pharmaceutical preparation and sealing the ampoule or vial. According to the method, high fillingspeed and low after-nitrogen-filling amount are adopted, and the amount of the residual oxygen at the top of the ampoule or vial and the defective product occurrence rate are effectively controlled.

Owner:上海聚可医药科技有限公司

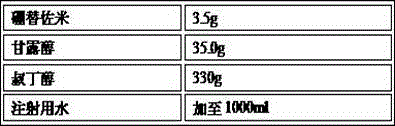

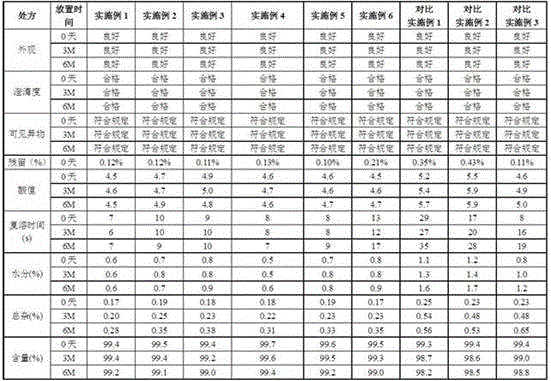

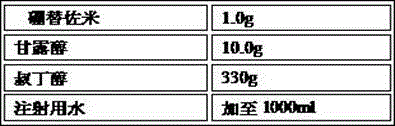

Bortezomib freeze-dried powder injection and preparation process thereof

ActiveCN106309385AImprove product stabilitySimple preparation processPowder deliveryDipeptide ingredientsFreeze dryBortezomib

The invention relates to a preparation process of freeze-dried powder injection containing bortezomib. The freeze-dried powder injection contains bortezomib and mannite. By controlling the oxygen content in a solution during preparation and a freeze-drying process, the stability of the bortezomib freeze-dried powder injection is greatly increased, and the re-dissolution time of the freeze-dried powder injection is shortened. The process provided by the invention is simple and easy, and is suitable for industrial production.

Owner:JIANGSU HANSOH PHARMA CO LTD

Part cleaning device for machine tool

InactiveCN104923519AImprove cleaning efficiencyImprove efficiencyCleaning using liquidsControl valvesMachine tool

The invention relates to a part cleaning device for a machine tool. The part cleaning device comprises a cleaning tank and a power supply device, wherein a material loading tray is arranged in the cleaning tank, a vibrating motor is arranged on the bottom surface of the material loading tray, and a drain pipe is connected to the bottom end of the cleaning tank; the lower end of the drain pipe is connected with a degassing device which is connected with an ultrasonic wave generation chamber through a connecting pipe; the ultrasonic wave generation chamber is connected with a water tank through an overflow pipe, and a heating device is arranged in the water tank; a water pipe is connected to one side of the water tank, and a spray pipe is arranged at the upper end of the cleaning tank; the spray pipe is connected with a water supply pipe, and a control valve is arranged on the water supply pipe; the vibrating motor, the degassing device, the ultrasonic wave generation chamber and the heating device are respectively connected with the power supply device. The part cleaning device disclosed by the invention solves the problems that the cleaning efficiency for parts of the machine tool is low, the parts are difficult to clean, and cleaning liquid cannot be recycled to cause waste.

Owner:SUZHOU YASIKE PRECISION CNC CO LTD

Edaravone sodium chloride injection liquid and preparation method thereof

ActiveCN110090225ASolve the problem of inconvenient long-term clinical medication due to the need for dilution and compatibilityImprove neurological symptomsOrganic active ingredientsNervous disorderVitamin CInjury brain

The invention relates to an edaravone sodium chloride injection liquid and a preparation method thereof. 100 ml of the injection liquid comprises 20-40 mg of edaravone, 0.6-1.0 g of sodium chloride, 100-150 mg of propylene glycol, 2.5-3.5 g of vitamin C, and 0.3-1.0 g of sodium hydrogen carbonate, wherein the pH is adjusted to 3.5-5.0. The preparation process of the injection liquid comprises thesteps: liquid preparation, filtration, filling, capping, sterilization and lamp inspection; liquid preparation adopts a two-step preparation method, and the preparation process adopts low temperaturepreparation. The adopted method is simple to operate and low in cost, and the prepared edaravone sodium chloride injection liquid has good drug stability and fewer side effects, can effectively reducethe generation of impurities, has high patient compliance with medication and safety, can be used for improving neurological symptoms, daily living activities and function disorder caused by acute cerebral infarction, and can effectively prevent and treat brain injury.

Owner:JINAN KANGHE MEDICAL TECH

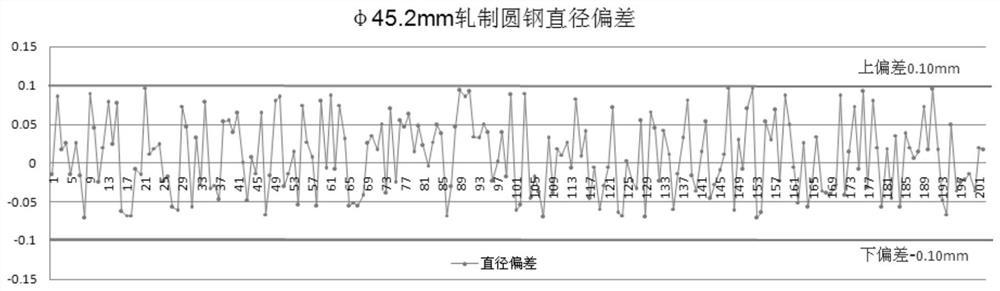

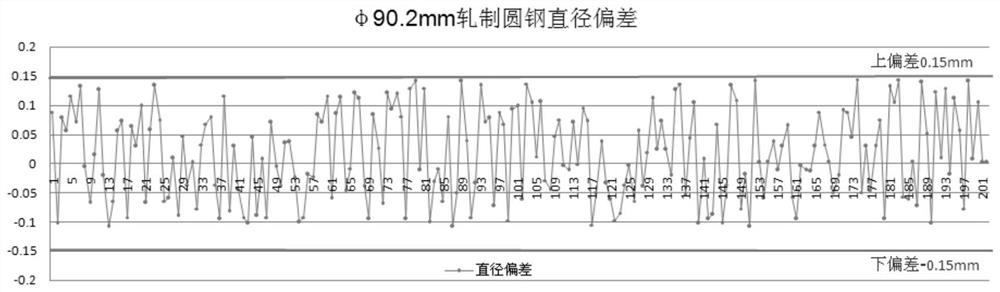

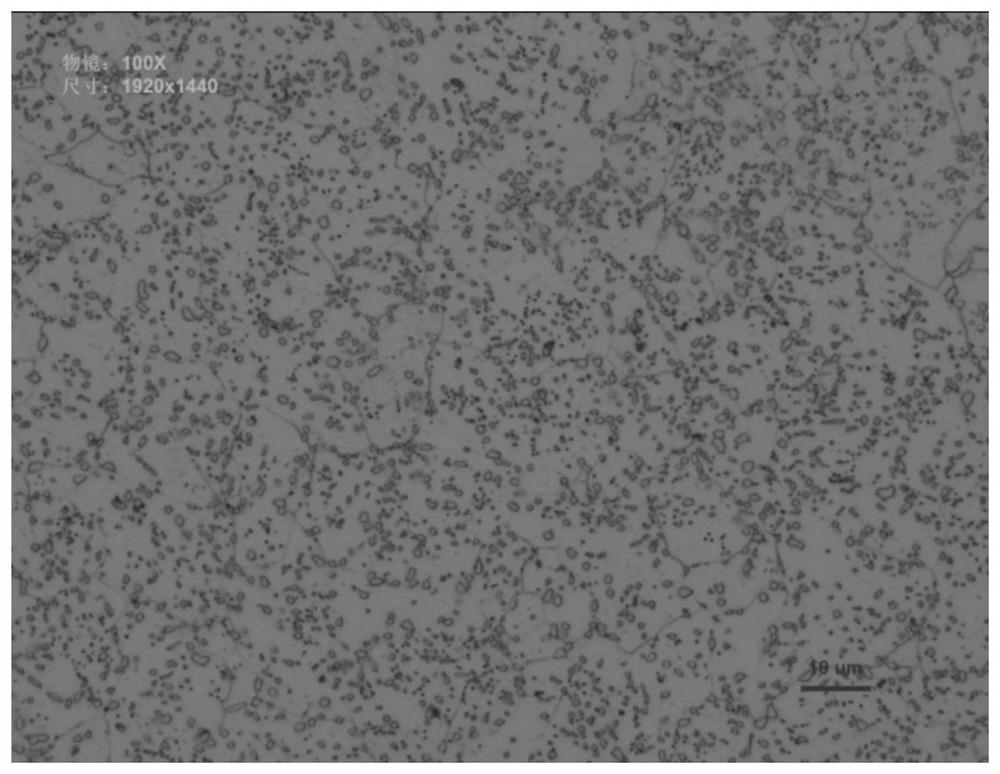

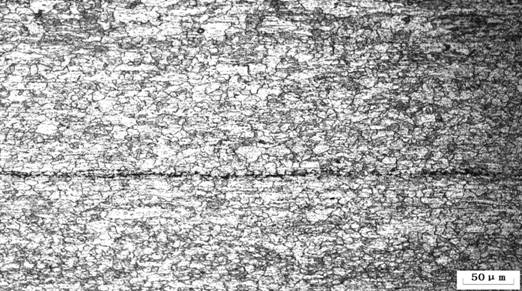

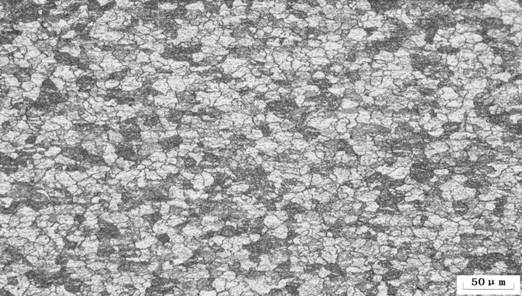

Low-silicon medium-carbon gear steel suitable for cold forging machining and manufacturing method thereof

ActiveCN112981233AInhibits the tendency to work hardeningStrong deoxygenation abilityFurnace typesHeat treatment furnacesGear wheelPearlite

The invention relates to low-silicon medium-carbon gear steel suitable for cold forging machining and a manufacturing method thereof. The steel comprises, by mass percent, 0.35-0.45% of C, smaller than or equal to 0.08% of Si, 0.30%-0.60% of Mn, 0.20-0.50% of Cr, smaller than or equal to 0.020% of P, 0.010-0.040% of S, smaller than or equal to 0.10% of Cu, smaller than or equal to 0.05% of Ni, smaller than or equal to 0.05% of Mo, smaller than or equal to 0.050% of Al, larger than or equal to 0.005% of N, 0.0005-0.0035% of B, smaller than or equal to 0.010% of Ti, smaller than or equal to 0.0020% of [O], smaller than or equal to 0.15% of (Cu+Ni+Mo) and the balance Fe and inevitable impurity elements Round steel with the specification being phi 45 mm to phi 90 mm is formed, and the size precision is smaller than or equal to + / -0.15 mm. According to GB / T 4162-2008, ultrasonic flaw detection on the interior of the round steel meets the A-level requirement. The outer layer of the section of the round steel is a partial decarburized layer, the depth of the partial decarburized layer is smaller than or equal to 0.5% d of the nominal diameter of the round steel, the core part is a matrix structure, the matrix structure is ferrite and spheroidized pearlite, and the spheroidization rate reaches 90% or above.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

A control method of residual oxygen in filling medicine packaging

ActiveCN111204487BReduce residual oxygenImprove oxidation stabilityPackaging by pressurising/gasifyingMedicineDrugs preparations

The invention belongs to the field of pharmaceutical packaging, and discloses a method for controlling the residual oxygen at the top of an ampoule or a vial in a pharmaceutical preparation, and a production method for filling a finished product in which the pharmaceutical preparation is filled and sealed in the ampoule or vial. The method adopts high filling speed and low post-filling nitrogen amount, and effectively controls the residual oxygen at the top of the ampoule or vial and the occurrence rate of defective products.

Owner:上海聚可医药科技有限公司

Nitrogen-charged packaging method

InactiveCN106697381AIncrease replacement rateSolve the problem that the amount of nitrogen filling is difficult to controlPackaging meatPackaging under special atmospheric conditionsNitrogenNitrogen gas

The invention belongs to the technical field of food packaging, in particular to a nitrogen-charged packaging method. According to the nitrogen-charged packaging method, selection of the vacuumizing degree and the quantity of charged nitrogen changes intelligently along with the weights of contents in packages, the main embodiment lies in that under the condition that the weights of products in packaging bags are different, the numerical value of the vacuum degree switching point corresponding to vacuumizing and the numerical value of the nitrogen switching point for nitrogen charging can change, and specifically, when the weight of the product in each packaging bag is 4-6 g, the vacuum degree is 0.08-0.12 MPa, and the quantity of charged nitrogen is 7-9 MPa. In this way, the packaging stability of the products is guaranteed, and the problem that the quantity of charged nitrogen is difficult to adjust and control when irregular food is packaged is solved; and airtightness of the packaging bags is better guaranteed, the original flavor of the products is maintained, the shelf life of the products is prolonged, and oxidization of greases and the like is restrained.

Owner:SHUNHUA DUCK INDAL DEVMET LINWU COUNTY HUNAN

Production method of high-carbon martensitic stainless steel steckel mill

ActiveCN113172089AControl heating rateReduce decarbonizationTemperature control deviceProcess efficiency improvementMartensitic stainless steelHeating furnace

The invention discloses a production method of a high-carbon martensitic stainless steel steckel mill, and relates to high-carbon steel produced by the steckel mill and a production process of the high-carbon steel. The process technology focuses on overcoming the defects of decarburization, peeling, edge cracking, layering and the like of high-carbon martensitic stainless steel, the defects of decarburization, peeling, edge cracking, layering and the like of the high-carbon martensitic stainless steel caused by long rolling time of the steckel mill are effectively overcome by controlling the tapping temperature, heating furnace residual oxygen, pass reduction, vertical roll rolling force, a descaling system and other processes, and the surface quality and the yield are improved.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

A pharmaceutical composition containing 18 kinds of amino acids

InactiveCN102626409BReduce residual oxygenAvoid huge investment in transformationOrganic active ingredientsPeptide/protein ingredientsSAFERAntioxidant

Owner:郑飞雄

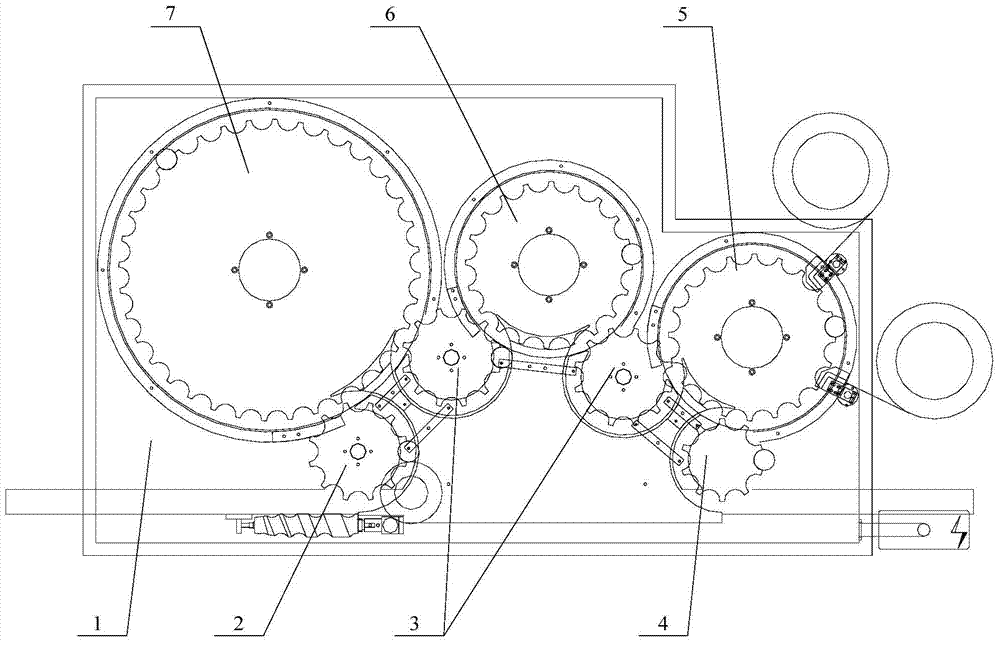

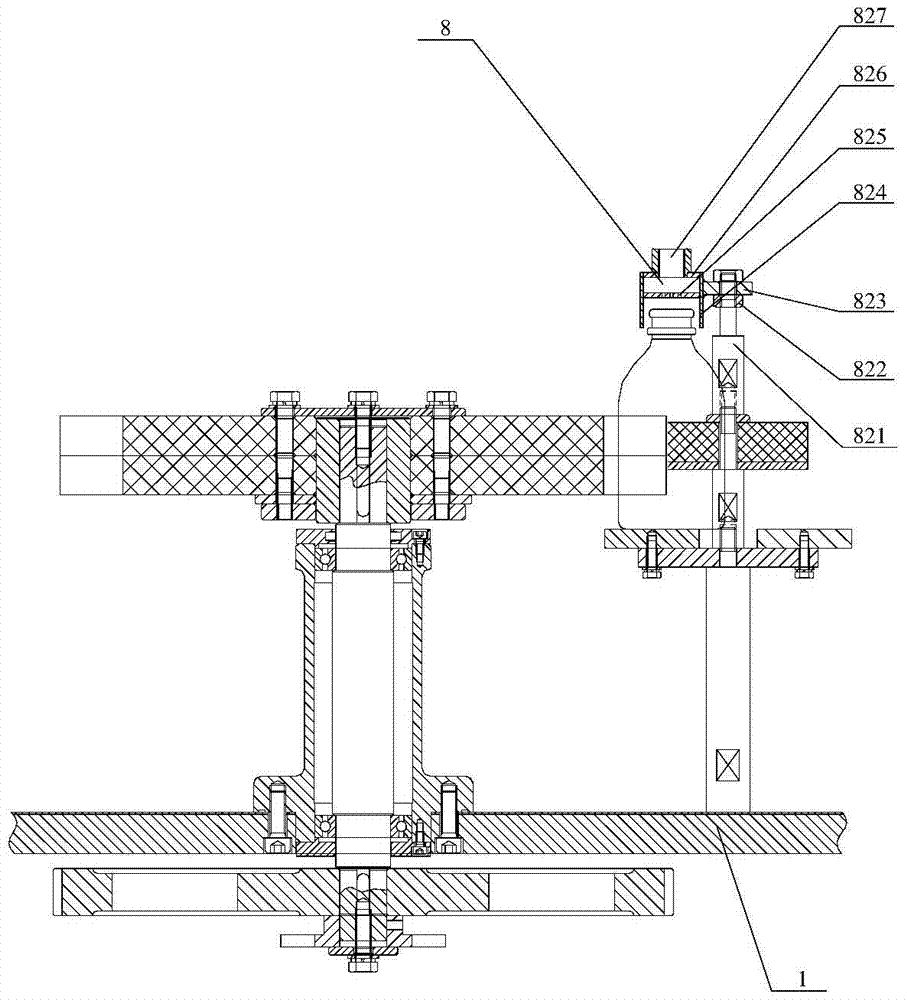

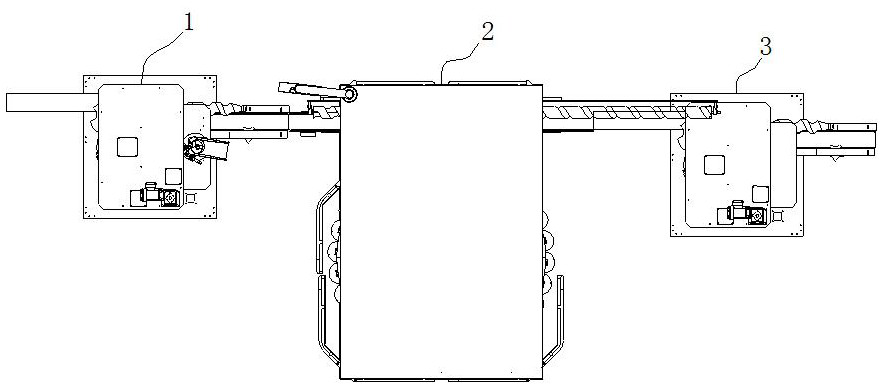

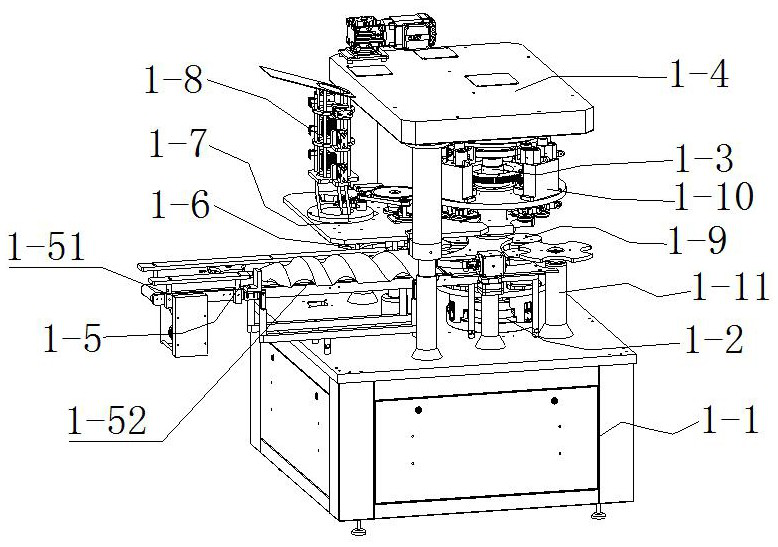

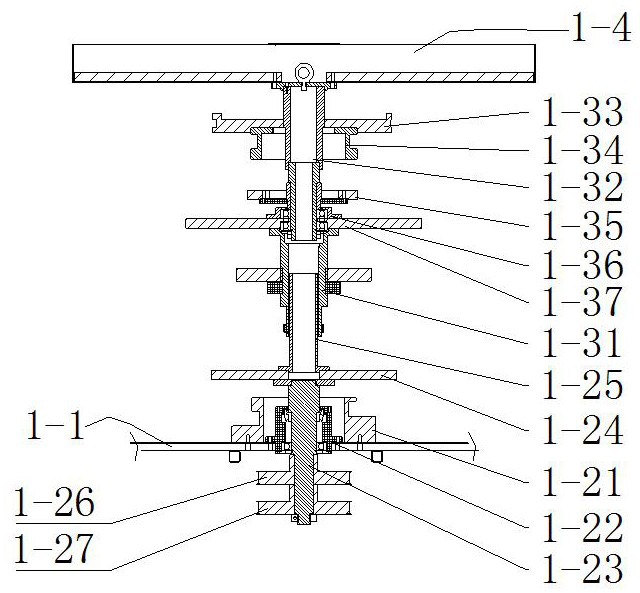

A large infusion liquid filling nitrogen filling stopper press machine

ActiveCN105217553BReduce residual oxygenLow costClosure using stoppersBottle-handling machinesProduction lineTamponade

The invention discloses a large infusion liquid filling nitrogen-filling stoppering machine, which comprises a frame and a bottle-feeding station, a filling station, a nitrogen-filling station after filling, and a corking station arranged on the frame and connected in sequence. The station and the bottle outlet station, the filling station and the nitrogen filling station after filling, the nitrogen filling station after filling and the corking station are all connected by a transition station. Among them, the bottle entry station and the transition station Each position is equipped with a nitrogen protection device for injecting nitrogen into the bottle body and mouth of the glass infusion bottle and forming a nitrogen coverage area at the mouth of the bottle; it can be seen that by adding a nitrogen protection device, the infusion bottle can be placed between each station. It is always in an environment full of nitrogen when traveling between spaces, which can effectively reduce the amount of residual oxygen in the bottle and make it meet the general control requirements. It does not need to seal and repeatedly vacuumize the infusion bottle. The cost is low and the production speed is not affected. It matches the production speed of other equipment on the production line, so it has excellent cost performance.

Owner:长沙汇一制药机械有限公司

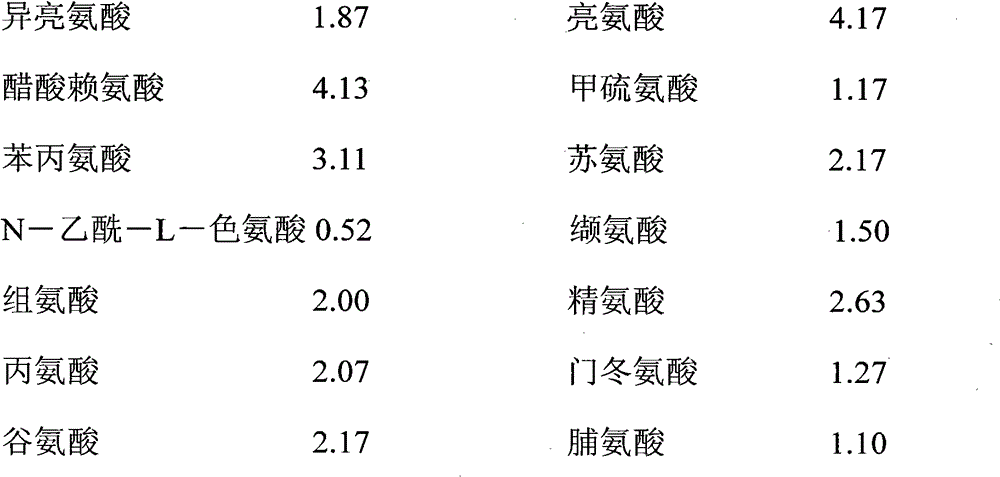

Pharmaceutical composition containing 17 amino acids

ActiveCN102552251BWidely used clinical populationMeet registration requirementsOrganic active ingredientsMetabolism disorderArginineTyrosine

The invention relates to a pharmaceutical composition containing 17 amino acids. The pharmaceutical composition comprises the following raw materials and auxiliary materials: proline, serine, alanine, isoleucine, leucine, tyrosine, glutamic acid, phenylalanine, arginine, lysine acetate, valine, threonine, histidine, tryptophan, methionine, acetylcysteine, glycine, sorbitol, and sodium bisulfite. The product is free of chlorine ion, and is wider in application crowd range; in the production, an acid or a base is not additionally added for adjusting the pH value; and the product is prepared according to the component ratio, and has the pH value of 5.5-7.0. Therefore, the pharmaceutical composition meets the pharmaceutical registering requirements that the material consumption is reduced and the production cost is lower, and has equivalent or better quality and stability as compared with the commercially available products.

Owner:湖北长联杜勒制药有限公司

Production method for reducing burning loss in Cr-Mo steel blank continuous furnace

PendingCN112815702AReduce burning lossReduce oxidationFurnace componentsFurnace typesTemperature controlHeating furnace

The invention discloses a production method for reducing burning loss in a Cr-Mo blank continuous heating furnace. The Cr-Mo steel alloy elements and the mass percentage meet the requirements of GB / T 713-2014. The method mainly comprises the steps of controlling the distances between a fuel spraying nozzle and an air nozzle in the furnace and a blank; controlling the lengths and the temperatures of a preheating section, a heating section and a soaking section in the continuous heating furnace; controlling the air-fuel ratio in the furnace to be 0.95-1.1, wherein the air-fuel ratio of the heating section is slightly larger than that of the soaking section; controlling the micro-positive pressure in the furnace, wherein the pressure is 0.3-0.5 MPa; and controlling the blank to enter the furnace while the blank is hot, wherein the temperature of the blank entering the furnace is 200-300 DEG C. According to a Cr-Mo steel plate produced through the method, the burning loss rate is controlled to be low during blank heating and is controlled to be 0.02-0.05%; the thickness of an iron sheet on the surface of the blank is small and is controlled to be 1-3 mm; and the surface quality of the rolled steel plate is good, and the grinding rate of the steel plate is 2-10%.

Owner:WUYANG IRON & STEEL

A high-speed vacuum filling and protective gas device

ActiveCN113955192BQuality improvementEasy to operatePackaging under vacuum/special atmosphereStructural engineeringPumping vacuum

Owner:CHANGZHOU JOYO AUTOMATION EQUIP CO LTD

Mixed type special deoxidizer for ham and preparation method

InactiveCN101700053BGuaranteed oxygen removal effectImprove short-term rapid deoxygenation speedMeat/fish preservation using chemicalsActivated carbonFood packaging

The invention relates to a mixed type special deoxidizer for a ham and a preparation method, belonging to the field of food packaging. The special deoxidizer is prepared by adopting fast acting chalcogenide deoxidizer and slow acting iron-based deoxidizer, and comprises the following components according to following proportioning 2.10-2.70 parts of Fe, 0.25-0.35 part of activated carbon, 0.06-0.08 part of Na2S2O4, 15-25 percent of H2O (w / wFe), 5-10 percent of NaCl and 25-35 percent of Ca (OH)2 (w / wNa2S2O4). The special deoxidizer for ham prepared by mixing can fast remove residual oxygen in vacuum package, can absorb penetrative oxygen of the package for a long time, efficiently prevent the fast oxidation and browning of section of the ham, continuously and stably absorb the oxygen within 12h, maintain certain oxygen absorption ability for a long time, satisfy the requirements of special antioxidation package of the prior cutout ham and prolong the storage period of the ham.

Owner:南京扬乾生物科技有限公司

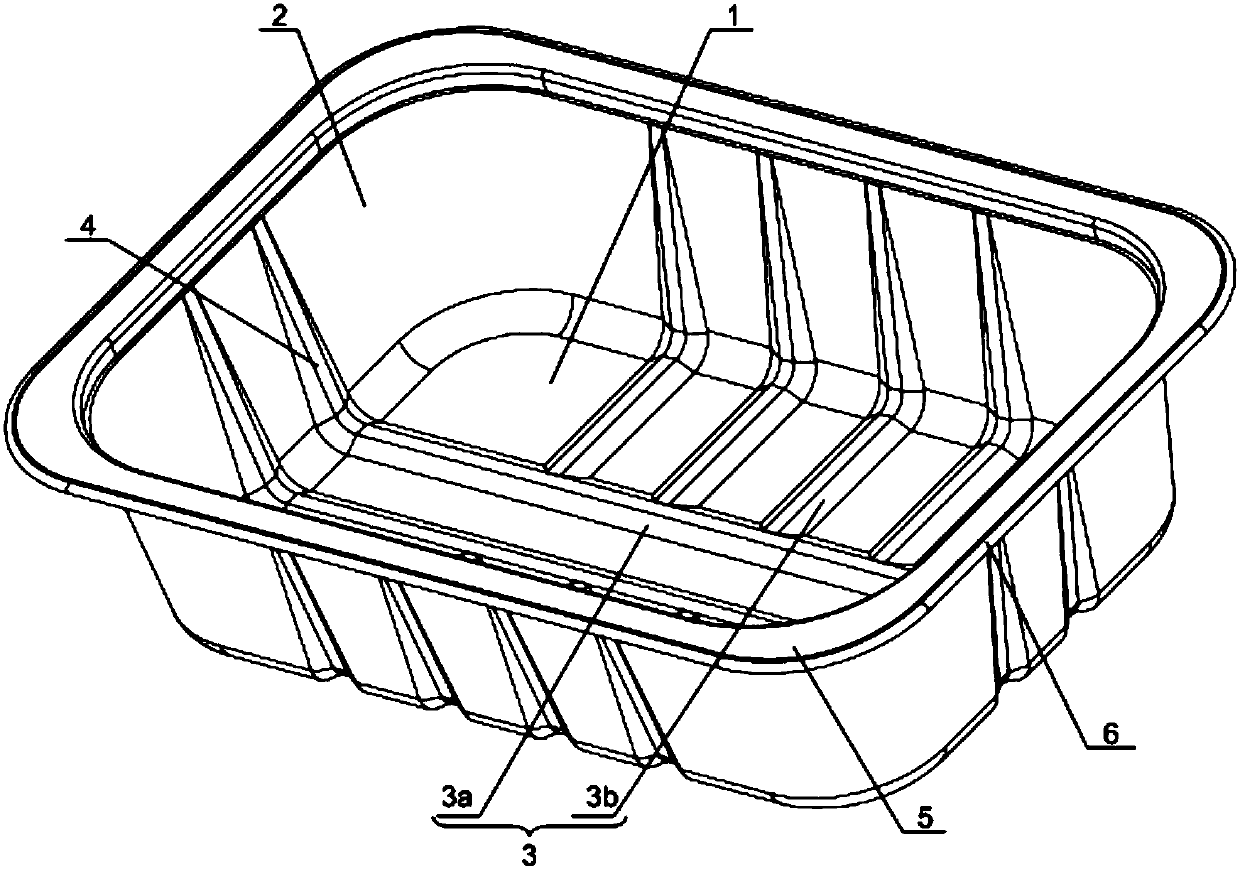

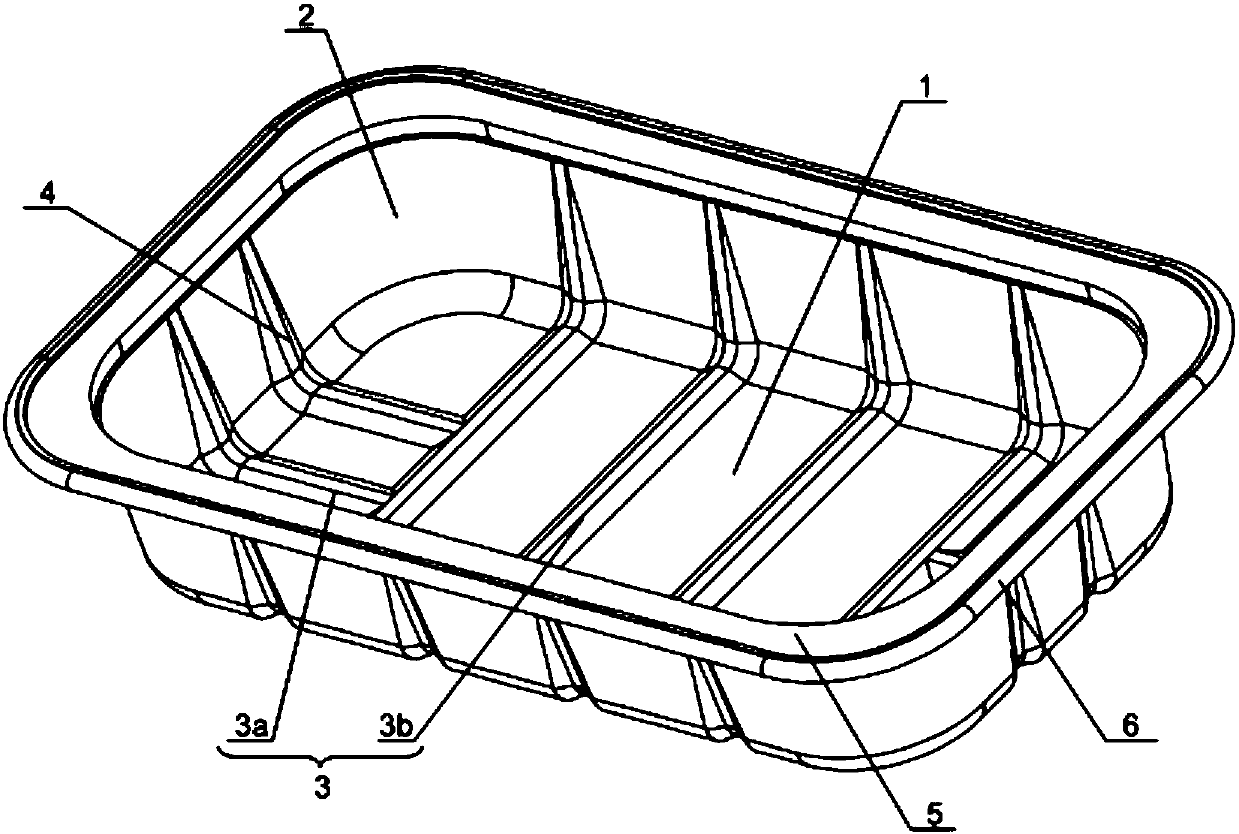

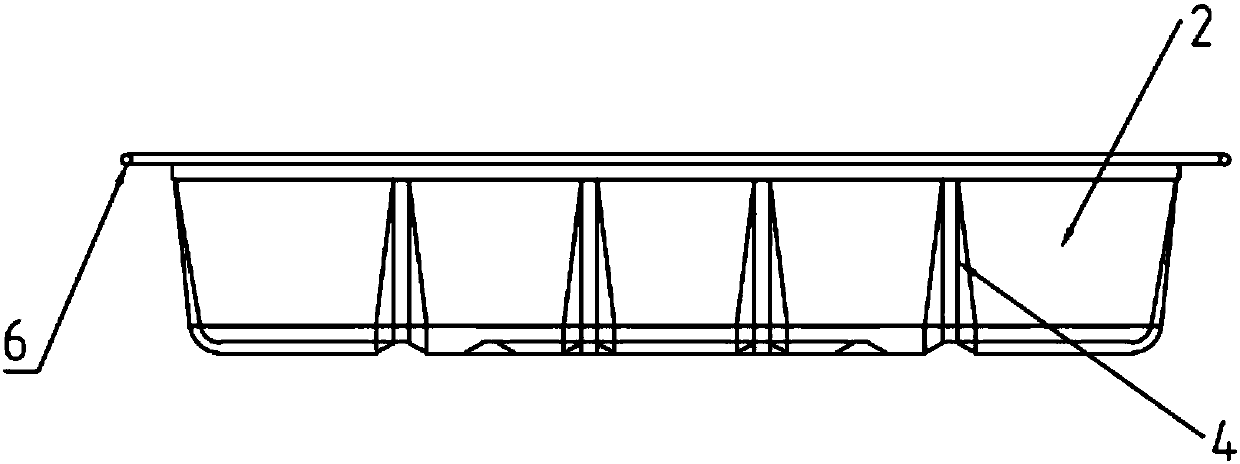

Aluminum foil container structure for food modified atmosphere packaging

PendingCN107618718AExtended shelf lifeUniform shelf lifeTray containersMetallurgyModified atmosphere

The invention discloses an aluminum foil container structure for food modified atmosphere packaging. The aluminum foil container structure comprises an aluminum foil box, the aluminum foil box is composed of an aluminum foil base plate and an aluminum foil circumferential side plate, one end of the aluminum foil circumferential side plate is provided with a smooth opening, the aluminum foil circumferential side plate is arranged in an inclined manner relative to the aluminum foil base plate, and the area of an opening plane of the aluminum foil circumferential side plate is larger than the area of the aluminum foil base plate; the aluminum foil base plate is provided with first reinforcing ribs inwards protruding towards the interior of the aluminum foil box, the aluminum foil circumferential side plate is provided with second reinforcing ribs inwards protruding towards the interior of the aluminum foil box, and the first reinforcing ribs and the second reinforcing ribs are communicated into a whole. The reinforcing ribs are connected into a whole, the rigidity of the box is improved, and meanwhile, the material thickness can be reduced; during air exchanger, air in most space isolated by the reinforcing ribs and located at the bottom of the container can be pumped out, the oxygen remaining rate is reduced to the maximum degree, and the food refreshing time is greatly prolonged. During food baking, heating is more even, and foods tightly attached to the box bottom cannot be burned in baking. In addition, an aluminum foil material can be repeatedly used and can be melted into an aluminum pig at the high temperature, and therefore environment protecting is achieved.

Owner:NINGBO TIMES ALUMINUM FOIL MFG

A kind of compound amino acid injection 18aa-v composition and preparation method thereof

ActiveCN103800323BInhibit or alleviate degradationGood effectOrganic active ingredientsPeptide/protein ingredientsAntioxidantTryptophan

The invention belongs to the technical field of medicines and particularly discloses a compound amino acid injection solution 18AA-V composition. The composition is composed of following components: arginine hydrochloride, histidine hydrochloride, leucine, isoleucine, lysine hydrochloride, phenylalanine, threonine, valine, methionine, tryptophan, glycine, alanine, proline, tyrosine, serine, cysteine hydrochloride, aspartate, glutamic acid, xylitol, malate and injection water; the composition does not contain a sulfite antioxidant; the malate is used as a pH (Potential Hydrogen) value adjusting agent, a metal ion chelating agent or a stabilizing agent; the bioavailability of various amino acids can also be improved; the cysteine hydrochloride is used as the antioxidant; nitrogen is filled in the whole production process to reduce the residual oxygen in the product, so that the quality of the product is better than that of similar compound amino acid injection solution products available on the market and the clinical utilization is safer.

Owner:湖北一半天制药有限公司

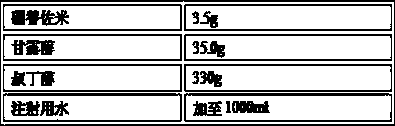

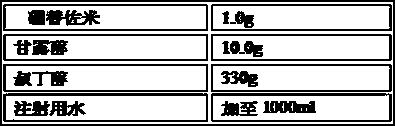

Bromhexine hydrochloride injection as well as preparation method and application thereof

PendingCN114699369AReduce residual oxygenImprove stabilityOrganic active ingredientsPharmaceutical delivery mechanismBenzoic acidBromhexina

The invention belongs to the technical field of bromhexine hydrochloride injection, and provides bromhexine hydrochloride injection as well as a preparation method and application thereof. According to the bromhexine hydrochloride injection provided by the invention, every 100 mL of the bromhexine hydrochloride injection consists of the following components: 0.1-1 g of bromhexine hydrochloride; the content of methyl p-hydroxybenzoate is 0.05 to 0.1 g; the content of propyl p-hydroxybenzoate is 0.01 to 0.06 g; the content of DL-tartaric acid is 0.1 to 0.35 g; a pH regulator and water for injection. The bromhexine hydrochloride injection provided by the invention takes methyl p-hydroxybenzoate and propyl p-hydroxybenzoate as bactericidal preservatives, so that the stability of the bromhexine hydrochloride injection is ensured under the condition of lower content.

Owner:QINGDAO AGRI UNIV

Bortezomib freeze-dried powder injection and preparation process thereof

ActiveCN106309385BReduce moisture contentLow oxygenPowder deliveryDipeptide ingredientsFreeze-dryingDissolution

The invention relates to a preparation process of freeze-dried powder injection containing bortezomib. The freeze-dried powder injection contains bortezomib and mannite. By controlling the oxygen content in a solution during preparation and a freeze-drying process, the stability of the bortezomib freeze-dried powder injection is greatly increased, and the re-dissolution time of the freeze-dried powder injection is shortened. The process provided by the invention is simple and easy, and is suitable for industrial production.

Owner:JIANGSU HANSOH PHARMA CO LTD

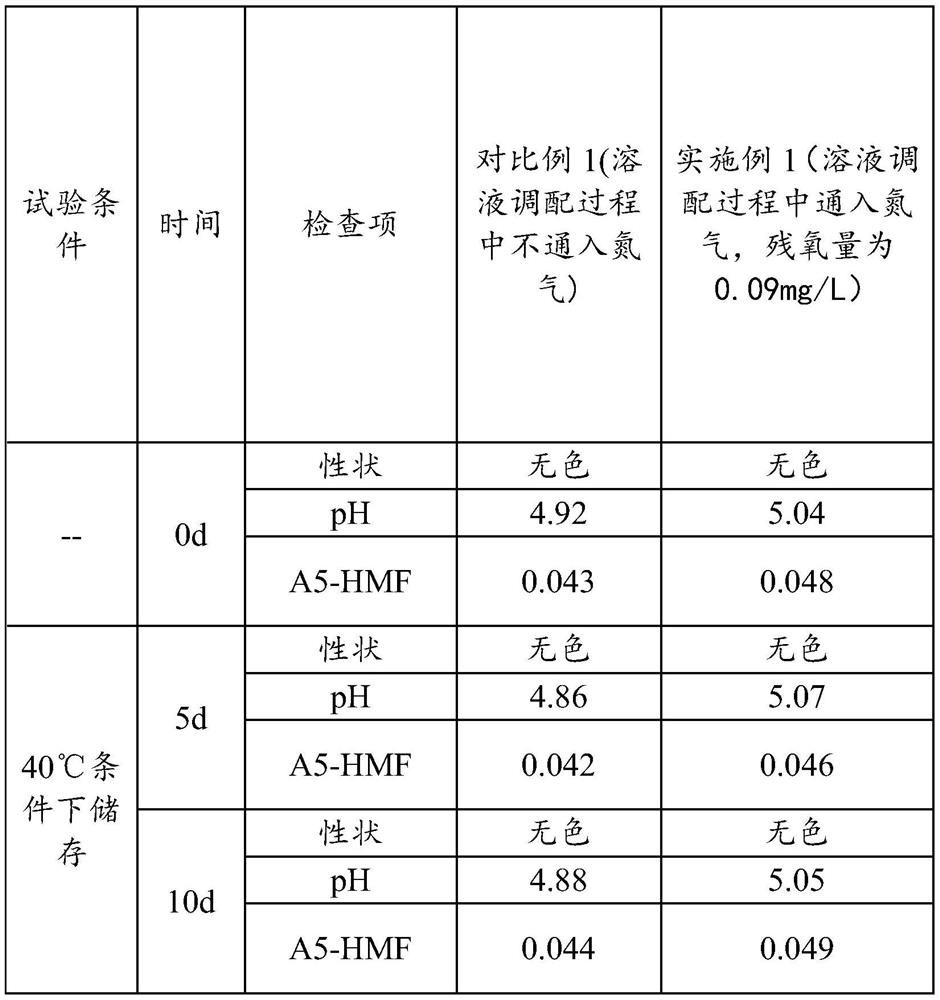

Preparation method of mixed sugar electrolyte injection and mixed sugar electrolyte injection prepared by preparation method

InactiveCN112603888ALess impuritiesHigh clarityHydroxy compound active ingredientsInorganic phosphorous active ingredientsPhysical chemistrySugar

The invention provides a preparation method of a mixed sugar electrolyte injection and the mixed sugar electrolyte injection prepared by the preparation method, which relate to the technical field of medical injections. According to the preparation method, the mixed sugar, the electrolyte component, the water and the pH regulator are used as raw materials to blend the solution. The preparation method comprises the following steps of firstly, dissolving mixed sugar and electrolyte components in part of water to obtain a solution A, adding a pH regulator into the solution A, adding the balance of water, and uniformly mixing to obtain a solution B, and sequentially carrying out refined filtration, filling and sterilization on the solution B to obtain the mixed sugar electrolyte injection. According to the preparation method, high-purity nitrogen subjected to sterilization and filtration is introduced in the solution blending process, and the residual oxygen content of the solution in the blending process is controlled to be 0.01-0.2 mg / L, so that the residual oxygen content in the solution is effectively reduced, degradation of related substances in the blended solution is greatly reduced, the product is purer, and the product quality is improved.

Owner:CHINA OTSUKA PHARM CO LTD

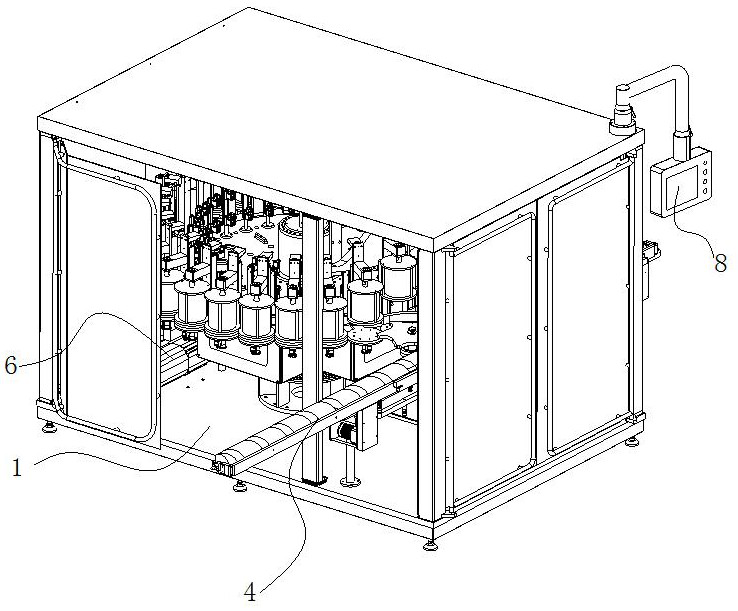

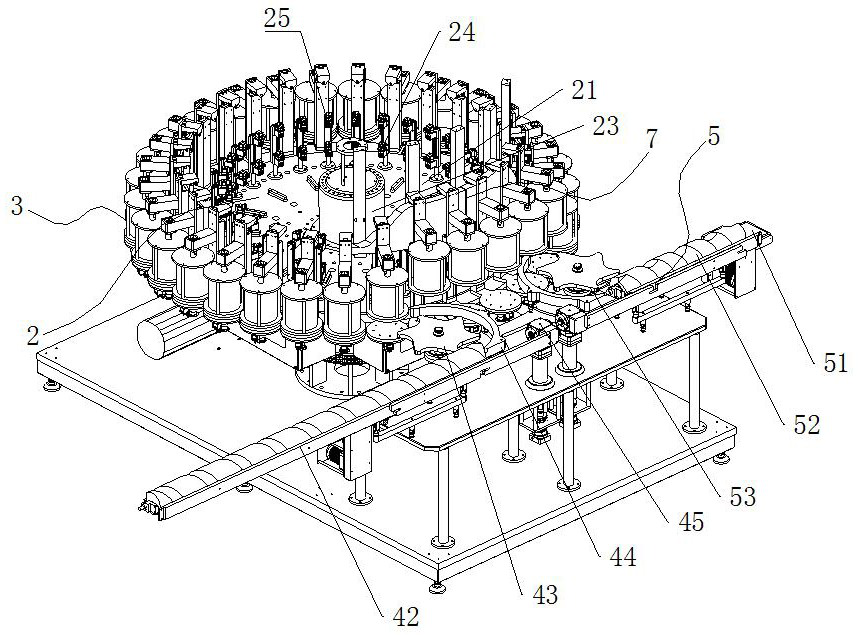

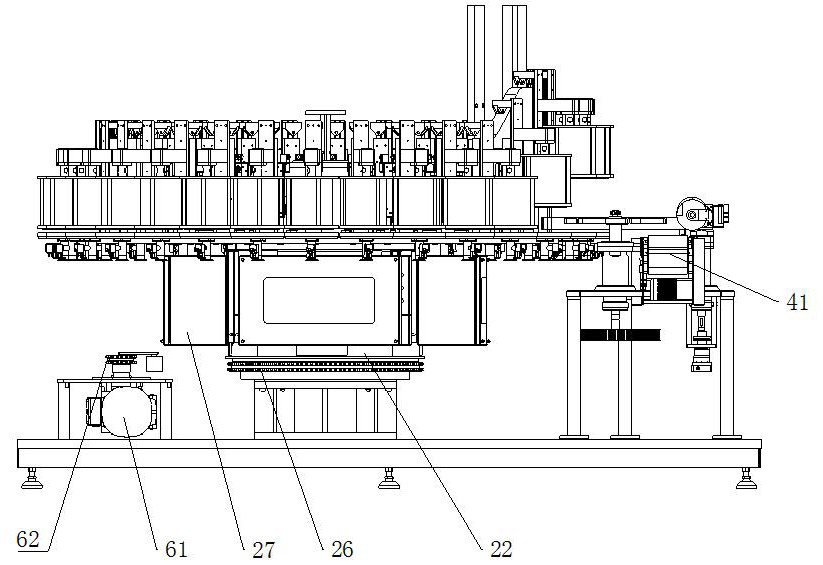

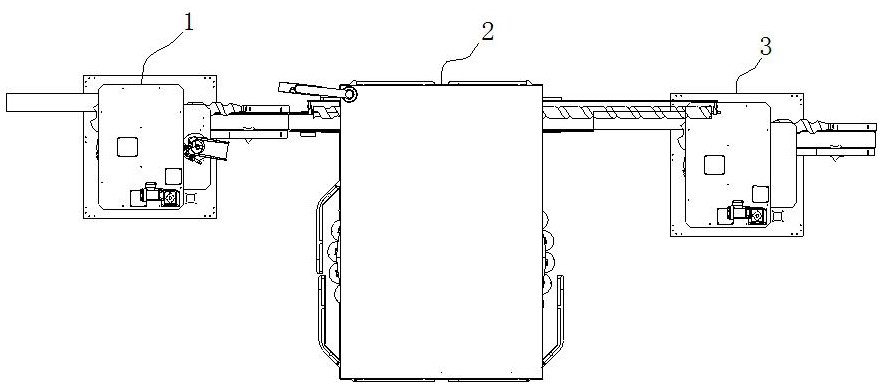

A High-speed Vacuumizing, Filling and Protecting Gas-Sealing Can Production Line

ActiveCN113955193BQuality improvementEasy to operatePackaging by pressurising/gasifyingFeed driveElectric machinery

Owner:CHANGZHOU JOYO AUTOMATION EQUIP CO LTD

A deep deoxidation device and its application

ActiveCN104694705BImprove deoxygenation capacityFast deoxygenationDispersed particle separationChemical reactionEngineering

Owner:CENT SOUTH UNIV

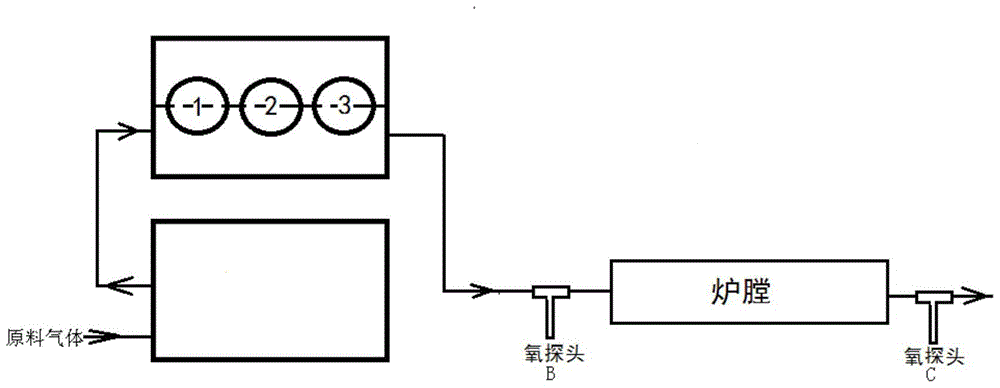

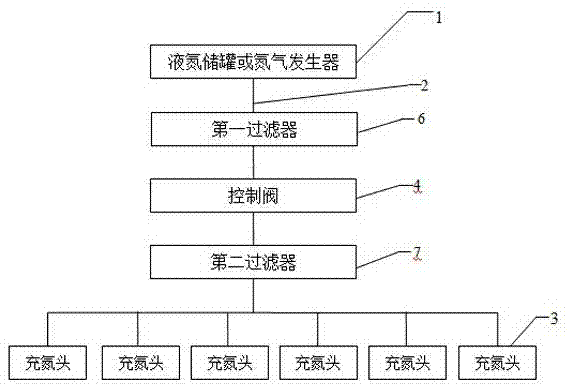

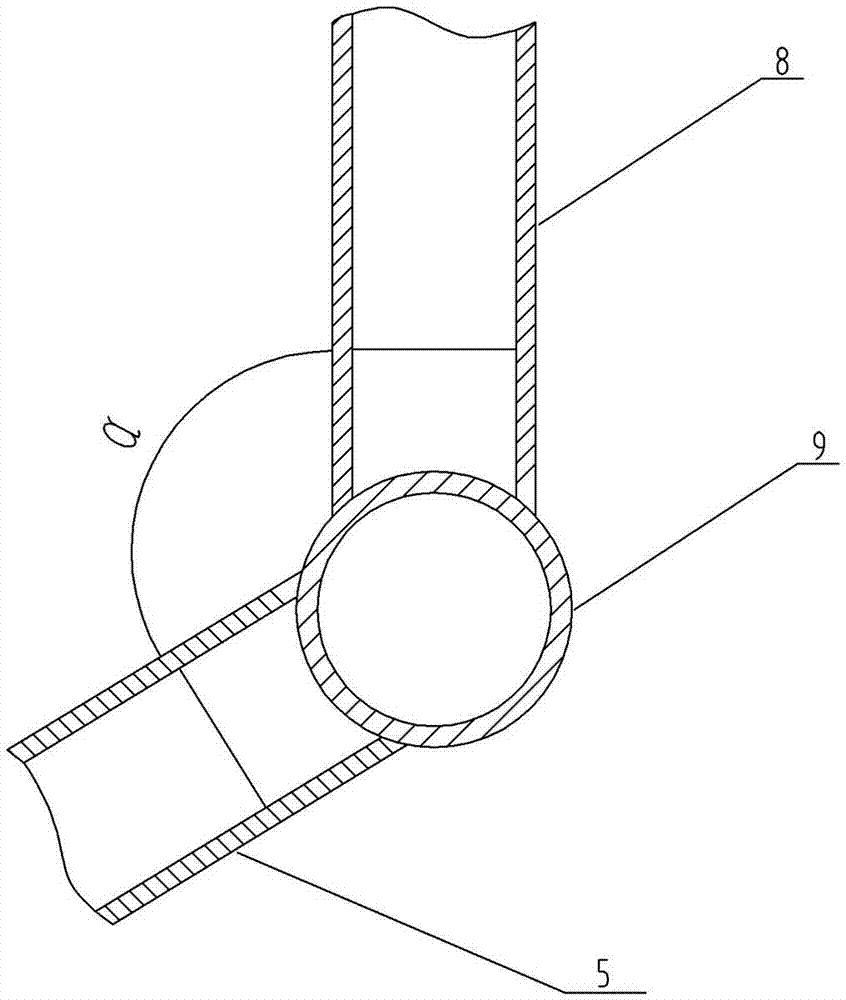

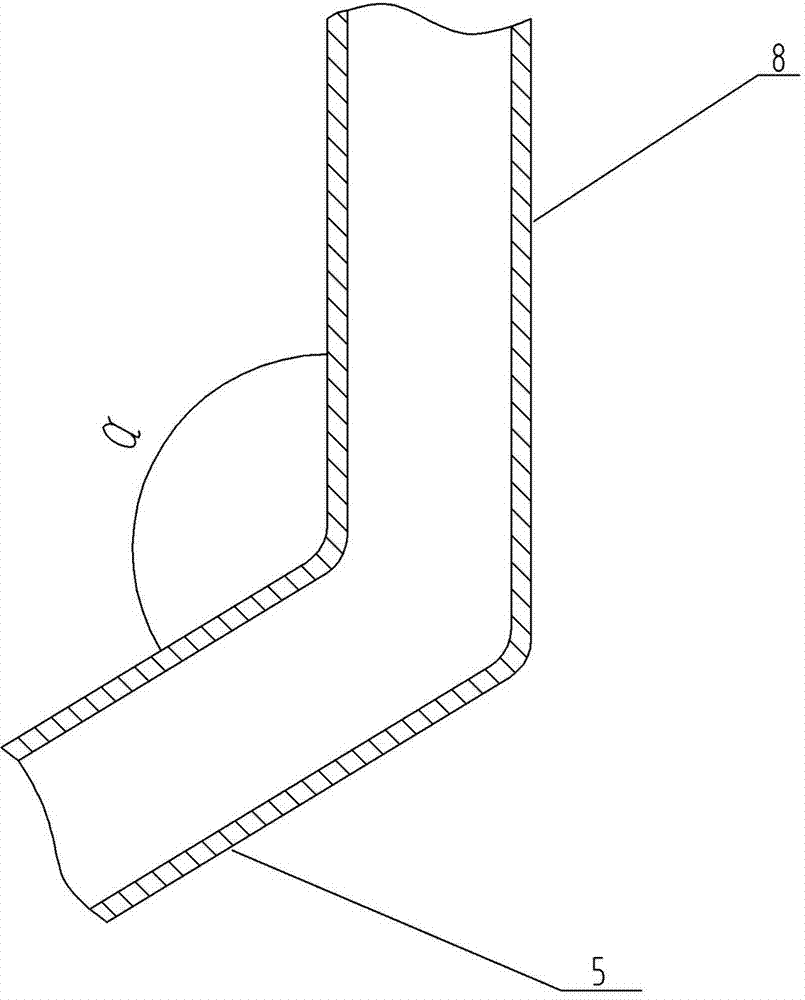

Method for controlling amount of remaining oxygen in powder injection preparation

ActiveCN102910312BGuaranteed chargingReduce residual oxygenPackaging by pressurising/gasifyingNitrogen generatorOxygen

The invention discloses a method for controlling the amount of remaining oxygen in a powder injection preparation, and the method comprises the steps that nitrogen from a liquid nitrogen storage tank or a nitrogen generator enters a filter through a conveying tube to be purified; the nitrogen purified in the previous step is filled in a powder injection package bottle by a nitrogen charging head; an included angle between 15 degrees to 75 degrees is formed between a gas outlet tube and a wall of the powder injection package bottle in the nitrogen charging process; and the bottle is sealed by a gland after being filled with the nitrogen. According to the method, as the included angle formed between the gas outlet tube of the nitrogen charging head and the wall of the powder injection package bottle is controlled, the nitrogen is blown out at a certain angle; the nitrogen is well charged into a container; furthermore, the nitrogen gas does not blow a powdery drug at the bottom of the bottle directly; the powdery drug is not blown out of the bottle; the method can reduce the amount of the remaining oxygen in the bottle significantly; the amount of the remaining oxygen is controlled to be less than 1.2%; and the stability of the drug is improved effectively.

Owner:GUANGZHOU BAIYUNSHAN PHARMA HLDG CO LTD BAIYUNSHAN PHARMA GENERAL FACTORY

High-speed vacuumizing and protective gas filling can sealing production line

ActiveCN113955193AQuality improvementEasy to operatePackaging by pressurising/gasifyingProduction lineElectric machinery

The invention relates to the technical field of food packaging, in particular to a high-speed vacuumizing and protective gas filling can sealing production line. The production line comprises a high-speed can pre-sealing machine, a high-speed vacuumizing and protective gas filling device and a high-speed solid can sealing machine which are connected through a conveying chain. The high-speed can pre-sealing machine is provided with a can sealing rack, a driving rotation mechanism, a pressing wheel transmission mechanism, a lifting mechanism, a can feeding mechanism, a can cover conveying drive mechanism, a cover discharging mechanism, a cover falling mechanism, a can hoisting and lifting mechanism, a pressing head mechanism, a can discharging mechanism and a drive mechanism. The production line is compact in structure, small in occupied area, high in can sealing and vacuumizing efficiency and capable of meeting the requirement of modern high-speed production. The can pre-sealing machine and the solid can sealing machine only need one motor to drive the driving rotation mechanism so as to drive the whole device to operate together. The production line can adapt to various can heights. The height is adjusted, and the vertical movement of a pressing head part and a pressing wheel rotating part can be completed through the forward and reverse rotation of a lifting motor, so that the distance between a can hoisting and lifting platform and a pressing head and a pressing wheel is adjusted. And manual adjustment is reduced to the greatest extent.

Owner:CHANGZHOU JOYO AUTOMATION EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com