Preparation method of mixed sugar electrolyte injection and mixed sugar electrolyte injection prepared by preparation method

An electrolyte injection and sugar-mixed technology, which is applied in the field of medical injections, can solve the problems of introduction, high residual oxygen in the solution, and poor quality of mixed sugar-electrolyte injection, and achieve the effect of high clarity and less impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] According to one aspect of the present invention, a preparation method of mixed sugar electrolyte injection, the preparation method comprises the following steps:

[0041] (a), providing mixed sugar, electrolyte components, water and pH regulator as raw materials;

[0042] (b), using the raw materials provided in step (a) to prepare the solution;

[0043] The preparation of the solution includes the following steps: first, the mixed sugar and electrolyte components are dissolved in part of the water to obtain a solution A; then the pH regulator is added to the solution A, and the remaining water is added to mix to obtain a solution B, and the solution preparation is completed ;

[0044] In the step (b) solution preparation process, feed high-purity nitrogen through sterilization and filtration, and control the residual oxygen content of the solution during the preparation process to be 0.01-0.2 mg / L;

[0045] (c) The solution B formulated in step (b) is subjected to f...

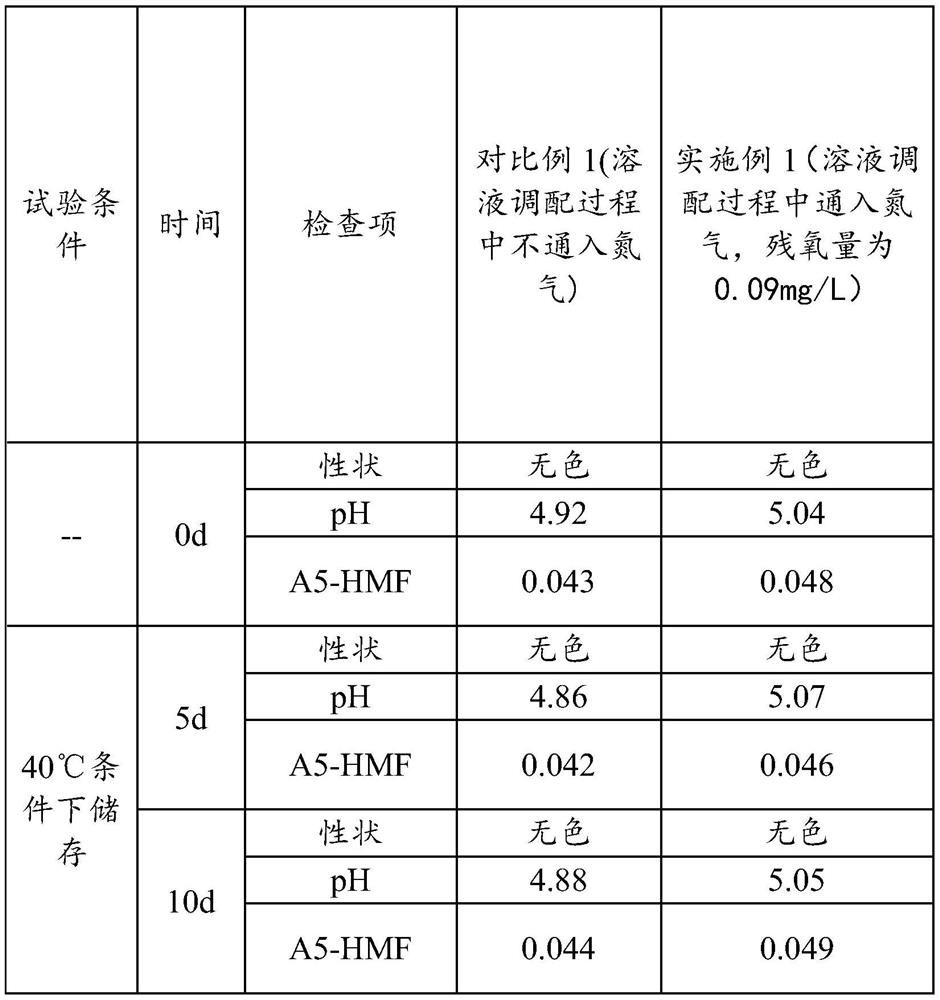

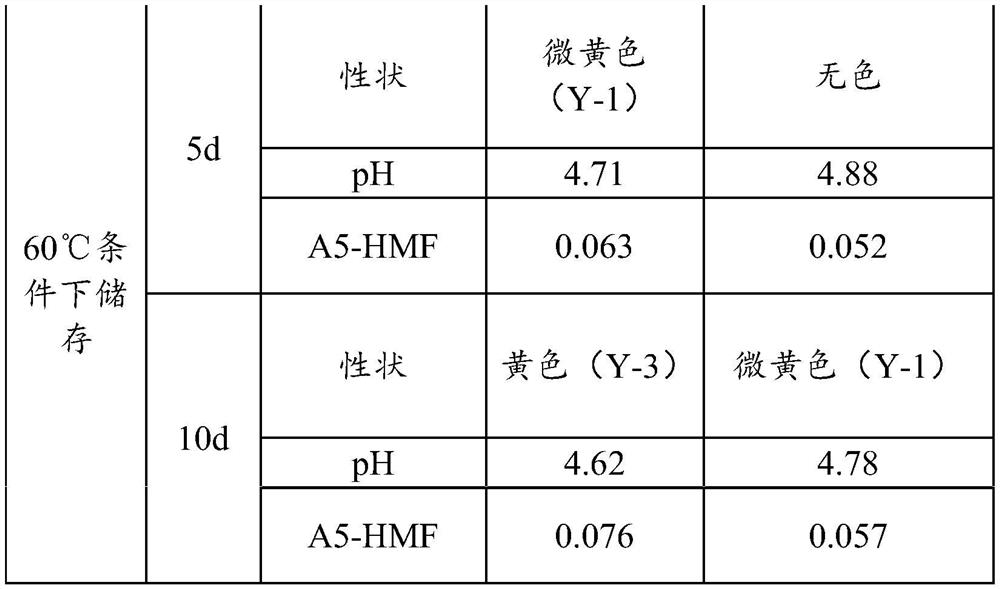

Embodiment 1

[0079] A preparation method of mixed sugar electrolyte injection, said preparation method comprising the following steps:

[0080] 1. Provide mixed sugar, electrolyte components, water and pH regulator as raw materials;

[0081] The composition of the raw materials is as follows: 730g of sodium chloride, 410g of acetic acid, 1140g of dipotassium hydrogen phosphate trihydrate, about 490g of citric acid, 185g of calcium chloride, 255g of magnesium chloride, 0.7g of zinc sulfate, 210g of sodium bisulfite, Anhydrous glucose 30000g, fructose 15000g, xylitol 7500g, water for injection about 440000 parts;

[0082] 2. Use a blending tank with a stirring paddle for liquid preparation, add 80% pre-prepared volume of water for injection, heat to boil, remove residual oxygen in the water for injection, and cool down at 40°C;

[0083] 3. Put sodium chloride, sodium acetate, dipotassium hydrogen phosphate trihydrate, citric acid, calcium chloride, magnesium chloride, zinc sulfate, sodium b...

Embodiment 2

[0087] A preparation method of mixed sugar electrolyte injection, said preparation method comprising the following steps:

[0088] 1, with embodiment 1;

[0089] 2. Use a blending tank with a stirring paddle for liquid preparation, add 80% pre-prepared volume of water for injection, heat to boil, remove residual oxygen in the water for injection, and cool down at 50°C;

[0090] 3. Put sodium chloride, sodium acetate, dipotassium hydrogen phosphate trihydrate, citric acid, calcium chloride, magnesium chloride, zinc sulfate, sodium bisulfite, anhydrous glucose, fructose, xylitol into the liquid mixing tank in sequence , stir for 30 minutes after putting in to dissolve all the raw materials, adjust the pH value of the solution to 5.06 with citric acid solution, add water for injection to the full amount, stir for 30 minutes and then take a sample to detect the intermediate. During the blending process, the sterilized Filtered high-purity nitrogen to control the residual oxygen o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com