Racking machine with nitrogen charging device

A filling machine and capping technology, which is applied in the direction of packaging, transportation and packaging, and special packaging items, etc., can solve the problems that the quality of medicines cannot be guaranteed, and achieve the effects of saving production time, prolonging storage time, and high nitrogen filling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, the present invention is described in further detail:

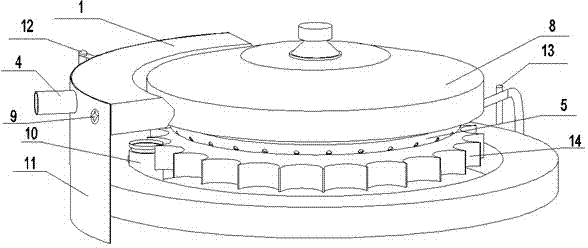

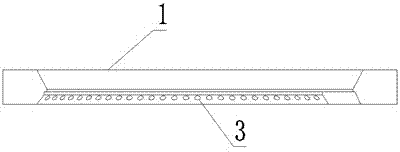

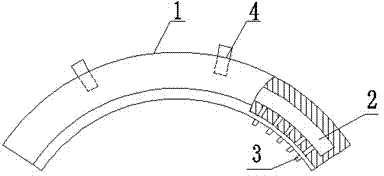

[0021] A subpacking machine with a nitrogen charging device, including a rotary capping machine and a nitrogen charging device, such as figure 1 As shown, the rotary capping machine is mainly composed of a capping tower 8 and a transfer wheel 14. The nitrogen filling device includes an arc nitrogen sealing body 1 and a nitrogen filling semicircle 5, an arc nitrogen sealing body 1 and a nitrogen filling semicircle Ring 5 is two independent nitrogen filling systems controlled by different valves and using different nitrogen sources respectively. The two systems can be used together or independently. Such as figure 1 As shown, the column I12 fixes the arc-shaped nitrogen sealing body 1 on the outside of the capping tower 8, but is not directly connected to the capping tower 8. Such as figure 2 , 3 with Figure 4 As shown, there is a gas chamber 2 inside the arc nit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com