A nitrogen pre-filling device for an air flow packing machine

A dispensing machine and pre-filling technology, which is applied in the direction of packaging objects, packaging, transportation and packaging under special gas conditions, can solve the problems of increasing the amount of raw powder feeding, increasing production costs, affecting the internal quality of drugs and drug properties, etc. To achieve the effects of ensuring the drug properties, reducing the oxidation rate, and facilitating installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with embodiment the present invention is described in further detail:

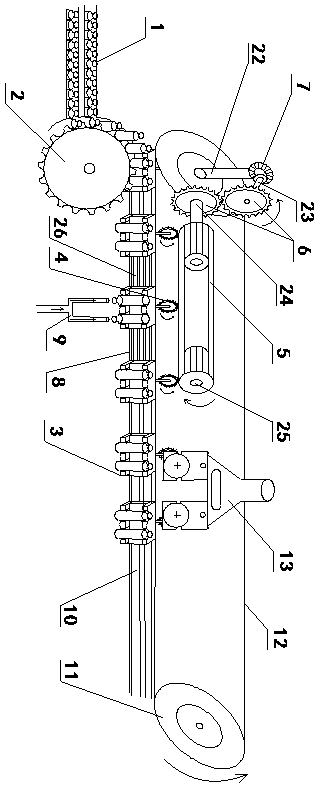

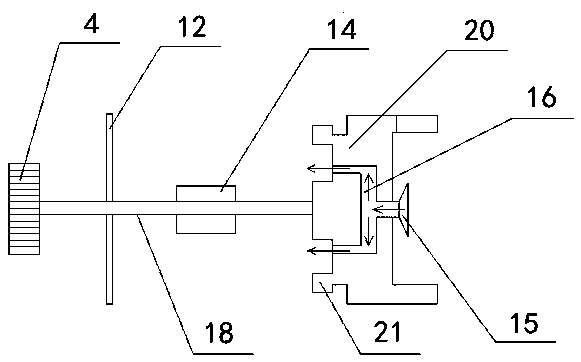

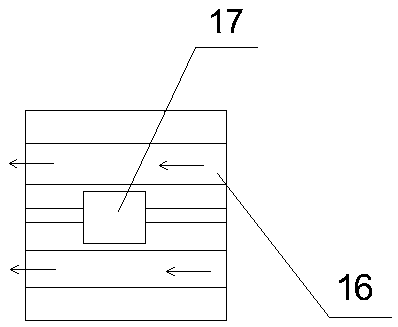

[0028] Such as figure 1 As shown, a nitrogen pre-filling device for an air flow packing machine includes a bottle feeding mechanism, a track block 3 with a guard rail, a transmission mechanism, a turning mechanism and a nitrogen charging mechanism.

[0029] The bottle-feeding mechanism comprises a bottle-feeding track 1 and a bottle-feeding dial 2, and the bottle-feeding track 1 comprises two rows of horizontal grooves side by side, and the bottle-feeding dial 2 is arranged horizontally, and its axis is vertical. The contact point between the bottle feeding track 1 and the bottle feeding dial 2 is at the left end of the bottle feeding dial 2, the contact point between the bottle feeding dial 2 and the track block 3 is at the rear end of the bottle feeding dial 2, and at the end of the bottle feeding dial 2 The difference between the above two places is 90 degrees.

[0030] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com