Device and method for producing medium and low melting point metals and oxide nitride powder

A technology for low melting point metals and nitrides, which is applied to the field of devices for producing medium and low melting point metals and oxygen or nitride powders, can solve the problems of low production efficiency, insufficient particle size, and difficult powder quality control, and achieves high production capacity, Excellent product quality and small equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

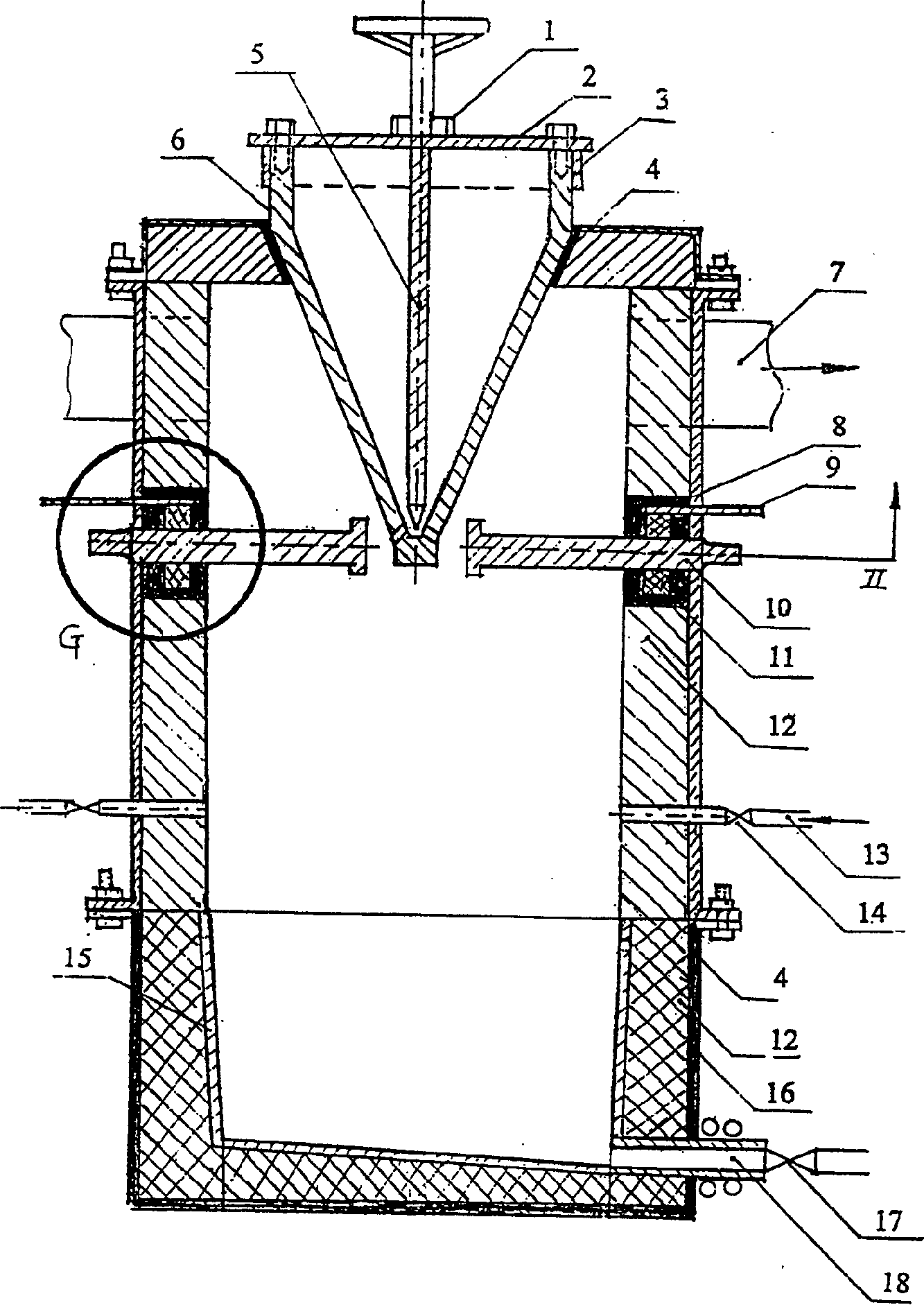

[0029] Implementation 1: Production of ultra-fine zinc powder by three-phase AC arc vaporization

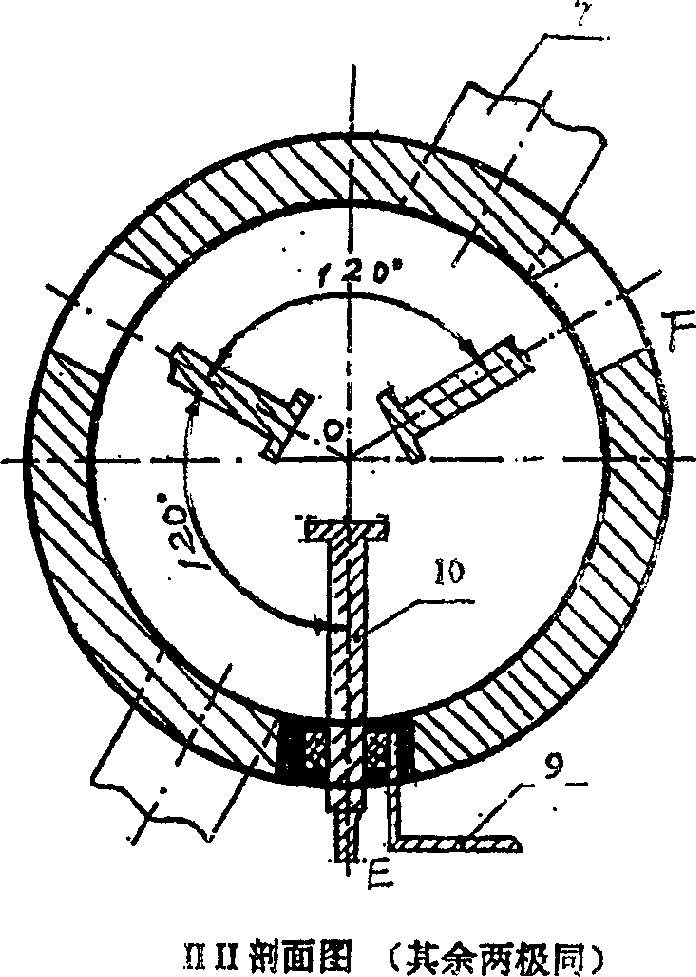

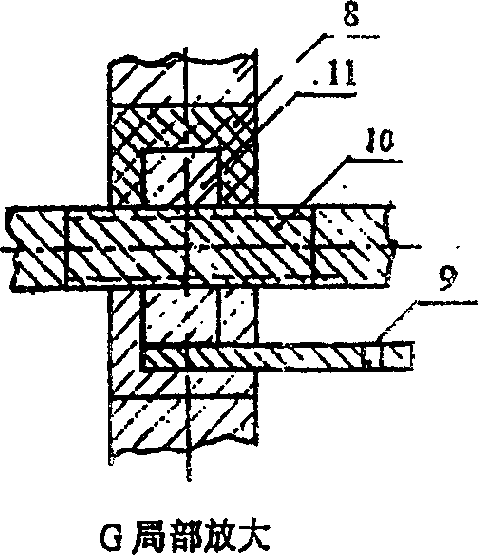

[0030] use figure 1 The operation process of the shown device to produce ultra-fine zinc powder is as follows: put No. 4 zinc (about 60 kg) into the graphite crucible, heat the crucible in a well-type resistance furnace to melt the zinc, and the zinc melt is overheated to 570 ℃, and then lift the zinc crucible with a crane to transfer the zinc melt into the conical graphite container of the three-phase arc vaporization device (6), and adjust the temperature of the zinc liquid in the conical graphite zinc container to not be lower than 470 ℃ (a 5KW spiral conical electric heating tube can be used below this temperature). Start the three-phase transformer to make the voltage of the three-phase live line to the neutral line reach 115 volts, and then start the conical control valve, and the zinc liquid will be ejected from the three horizontal thin runners (20), and the impact will ...

Embodiment 2

[0032] Implementation 2: Production of ultrafine Al by three-phase AC arc vaporization 2 o 3 powder

[0033] use figure 1 The device shown produces Al 2 o 3 Powder, with No. 4 aluminum as raw material, its equipment and operation process are all identical with embodiment 1, and difference only has three points: (1) the aluminum liquid that transfers in the conical graphite container (6) from resistance melting furnace should keep Above 720°C, and below 720°C, the spiral conical auxiliary electric heater should be started to raise the temperature above this temperature; (2) The protective gas fed into the vaporizer is no longer nitrogen or argon, but industrial oxygen with a purity of 99.5% . This oxygen will oxidize the aluminum vapor formed during arc vaporization to Al 2 o 3 (3) When producing metal oxides, the sealing measures of the powder collection system do not need to be strict, and proper air leakage is also beneficial to further oxidize the unoxidized aluminum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com