Silicon oil filling machine

A technology of filling machine and silicone oil, applied in liquid distribution, special distribution device, packaging, etc., can solve the problems of waste of silicone oil, long time required, inaccurate filling amount, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

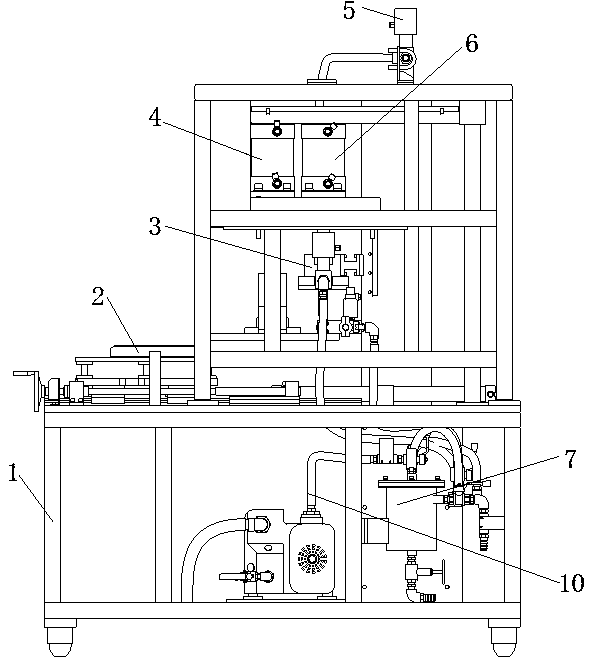

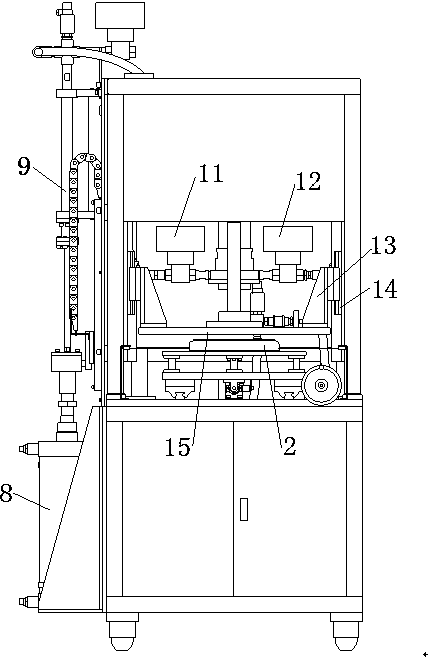

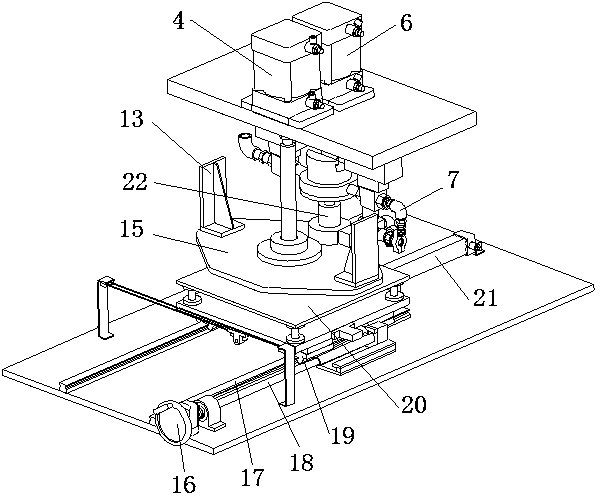

[0018] Such as figure 1 and figure 2 As shown, the structure of the silicone oil filling machine of the present invention mainly includes a frame 1, a positioning device 2, an oil supply device, a filling mechanism 3, a suction cleaning device and a vacuum pipeline. The positioning device 2, the oil supply device, the filling mechanism 3, the back suction cleaning device and the vacuum pipeline are all arranged on the frame 1, the filling mechanism 3 is located above the positioning device 2, and the filling mechanism 3 is connected with the oil supply device, the back suction cleaning The device is connected to the vacuum line. One end of the vacuum pipeline is connected with a vacuum pump 10 . The positioning device 2 is used for placement, movement and positioning of the crankshaft damper. The oil supply device is used for the delivery of silicone oil. The vacuum pump 10 and the vacuum pipeline are used to extract the air in the silicone oil shock absorber. Filling me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com