Snow melting bituminous mixture modifier and preparation method thereof

An asphalt mixture and modifier technology, which is applied in the field of asphalt materials, can solve the problems of non-renewable resource consumption, human lack of materials, and increase production costs, and achieve the effects of high cost performance, low cost, and reduced loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028]Simultaneously, the present invention also provides a kind of preparation method of snow-melting asphalt mixture modifier, and described preparation method comprises the following steps:

[0029] A. Add 80-90 parts by weight of seawater into the heating tank, heat to 40-60°C, and stir for 5-10 minutes;

[0030] B. After the stirring is completed, put 1 to 10 parts by weight of the porous material into the heating tank and soak for 20 to 80 minutes;

[0031] C. Filter out seawater, put the residue into an oven, and dry at 80-100°C for 1-5 hours to obtain a dried porous material;

[0032] D. Preheat the waste oil of 0-20 parts by weight to 100-140° C., immerse the dried porous material obtained in step C in the waste oil, stir for 10-30 minutes, and then filter the waste oil to obtain the obtained Describe snow-melting asphalt mixture modifier.

[0033] The present invention will be further described in conjunction with specific implementation examples below.

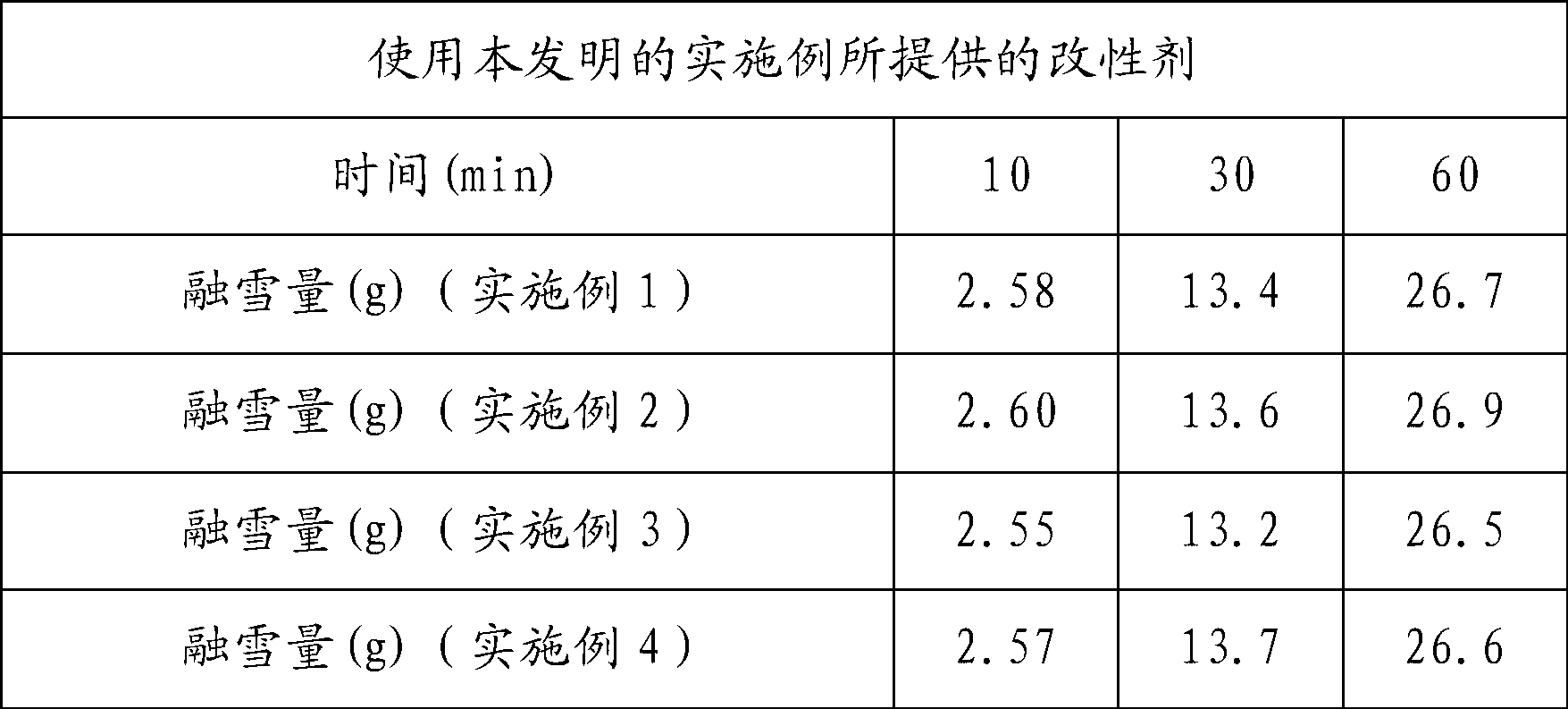

Embodiment 1

[0035] In parts by weight, pour 80 parts of seawater with a salinity of 10‰ into the heating tank, heat to 50°C, and stir rapidly for 5 minutes; then stop stirring, and put 5 parts of seawater with a particle size of 1 to 2 mm and a specific surface area of 350 to 600m 2 / g, activated carbon particles with a pore size of 1-150nm are immersed in a heating tank for 30 minutes; the seawater is filtered off, the residue is placed in an oven, and dried for 3 hours at 80°C; after that, 15 parts of waste oil are preheated and To 120°C, soak the dried activated carbon particles impregnated with seawater, stir rapidly for 15 minutes; finally filter out the waste oil, and the remaining residue is a new snow-melting asphalt mixture modifier.

Embodiment 2

[0037] In parts by weight, 90 parts of seawater with a salinity of 80‰ was poured into the heating tank, heated to 60°C, and stirred rapidly for 8 minutes; then the stirring was stopped, and 6 parts of seawater with a particle size of 0.01 to 0.5 mm and a specific surface area of 400~780m 2 / g, powdered activated carbon with a pore size of 2-100nm is immersed in a heating tank for 50 minutes; the seawater is filtered off, the residue is placed in an oven, and dried at 100°C for 3.5 hours; after that, 4 parts of waste oil are preheated, and Heat to 100°C, soak the dried activated carbon particles impregnated with seawater, stir rapidly for 20 minutes; finally filter out the waste oil, and the remaining residue is a new snow-melting asphalt mixture modifier.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com