Seed coating agent and coated seeds for desert control and aerial seeding, and preparation method of agent

A technology of coated seeds and coating agents, applied in the fields of coated seeds and their preparation, afforestation seed drought-resistant coating agents, and coating agents for seeds used in aerial sowing for sand control and afforestation, can solve the problems of low survival rate, pilling hardness and Disintegration conflicts and other problems, to achieve the effect of improving the seed rate, not easy to stick, and high seed rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

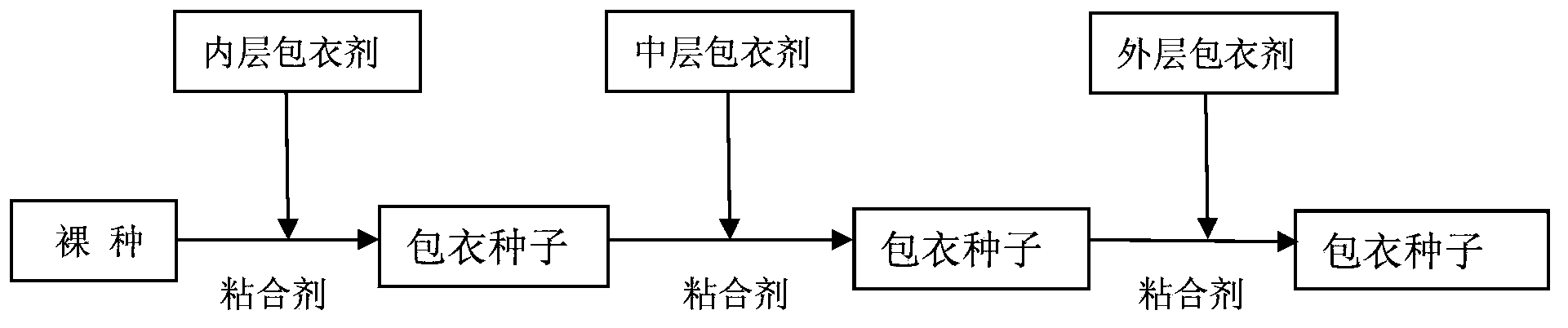

Method used

Image

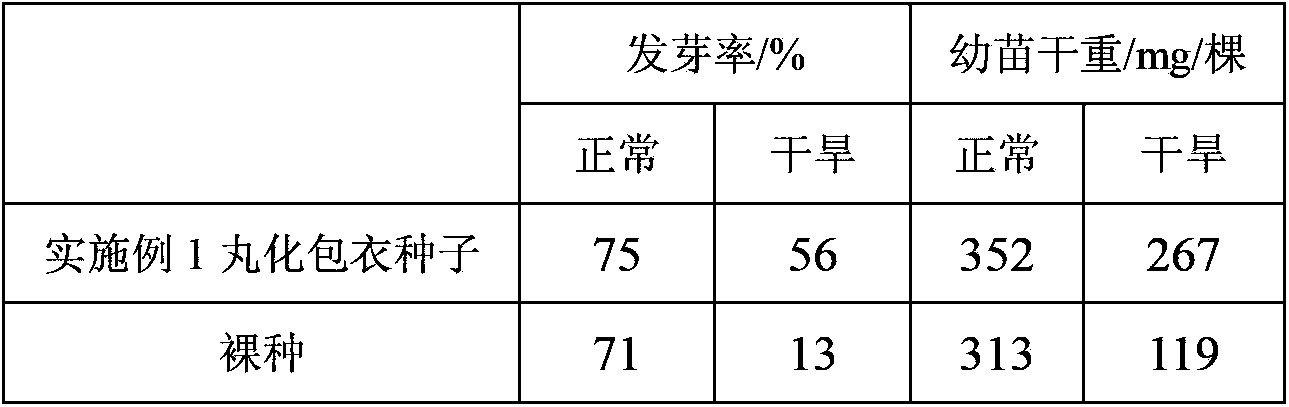

Examples

Embodiment 1

[0059] Embodiment 1 prepares Caragana drought-resistant coated seeds

[0060] 1. Caragana seed pretreatment

[0061] Adopt natural winnowing or mechanical winnowing to remove impurities, dust and unfulfilled seeds, and obtain Caragana pretreated seeds;

[0062] 2. Preparation of coating agent

[0063] 1) Prepare inner coating agent

[0064] 1-A) Grinding the water retaining agent, attapulgite clay, and talc separately to obtain water retaining agent powder, attapulgite clay powder, and talc powder with a particle size ≥ 200 mesh;

[0065] 1-B) Mix water-retaining agent powder, attapulgite clay powder, and talcum powder evenly to prepare an inner layer coating agent for later use. The weight ratio of water-retaining agent powder, attapulgite clay powder, and talc powder is 20:100: 47. The water-retaining agent is French Eisen water-retaining agent;

[0066] 2) Preparation of intermediate layer coating agent

[0067] 2-A) Separately pulverize potassium nitrate, potassium di...

Embodiment 2

[0084] Embodiment 2 prepares Caragana drought-resistant coated seeds

[0085] 1. Caragana seed pretreatment

[0086] Adopt natural winnowing or mechanical winnowing to remove impurities, dust and unfulfilled seeds, and obtain Caragana pretreated seeds;

[0087] 2. Preparation of coating agent

[0088] 1) Prepare inner coating agent

[0089] 1-A) Grinding the water retaining agent, attapulgite clay, and talc separately to obtain water retaining agent powder, attapulgite clay powder, and talc powder with a particle size ≥ 200 mesh;

[0090] 1-B) Mix the water-retaining agent powder, attapulgite clay powder, and talc powder evenly to prepare the inner layer coating agent for later use. The weight ratio of water-retaining agent powder, attapulgite clay powder, and talc powder is 10:100: 40. The water-retaining agent is French Eisen water-retaining agent;

[0091] 2) Preparation of intermediate layer coating agent

[0092] 2-A) Separately pulverize potassium nitrate, potassium...

Embodiment 3

[0109] Embodiment 3 prepares flower bar drought-resistant coated seed

[0110] 1. Pretreatment of flower stick seeds

[0111] Use natural winnowing or mechanical winnowing to remove impurities, dust and unfulfilled seeds, and obtain flower stick pretreated seeds;

[0112] 2. Preparation of coating agent

[0113] 1) Prepare inner coating agent

[0114] 1-A) Grinding the water retaining agent, attapulgite clay, and talc separately to obtain water retaining agent powder, attapulgite clay powder, and talc powder with a particle size ≥ 200 mesh;

[0115] 1-B) Mix the water-retaining agent powder, attapulgite clay powder, and talcum powder evenly to prepare the inner layer coating agent, and set it aside. The weight ratio of water-retaining agent powder, attapulgite clay powder, and talc powder is 25:100: 60. The water-retaining agent is French Eisen water-retaining agent;

[0116] 2) Preparation of intermediate layer coating agent

[0117] 2-A) Separately pulverize potassium n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com