Seed rolling pelleting equipment

A technology for making pellets and equipment, applied in the direction of seed coating/seed dressing, etc., can solve the problems of high seedless rate, high multi-seed rate, low production efficiency, etc., and achieve low seedless rate, high single-seed rate, high adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

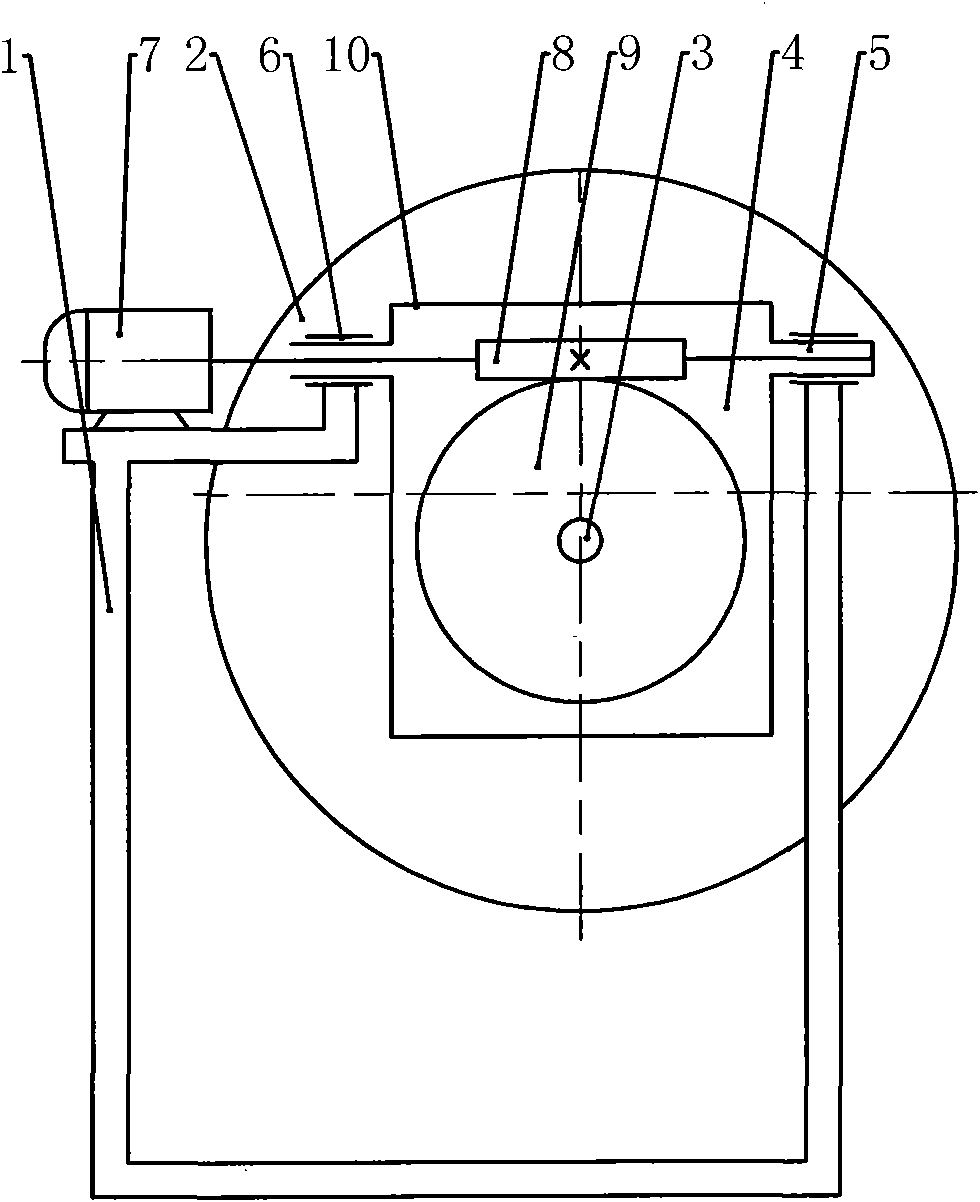

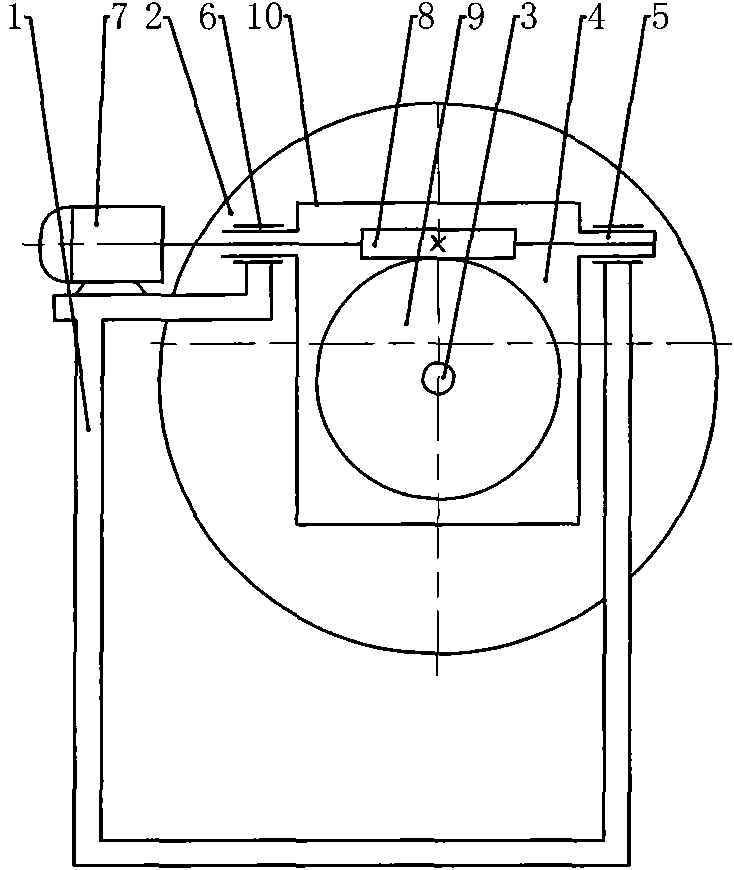

[0009] Such as figure 1 As shown, the present invention consists of a frame (1), a rotary kettle (2), a central shaft (3), a worm gear reducer (4), a support shaft (5), a sliding bearing seat (6), a stepless speed regulating motor (7) and other components. The central shaft (3) is installed on the outside of the rotary kettle (2) and is concentric with the rotary center of the rotary kettle (2), and the central shaft (3) is inserted into the rotation center hole of the turbine (9) of the worm gear reducer (4), and the worm gear The supporting shaft (5) is installed on the housing (10) of the reducer (4), and the inside of the supporting shaft (5) is hollow, coaxial with the worm (8), and the worm (8) passes through the hollow supporting shaft (5 ) is mechanically connected with the stepless speed regulation motor (7), the stepless speed regulation motor (7) is fixed on the frame 1, and the worm gear reducer (4) is installed on the on rack 1.

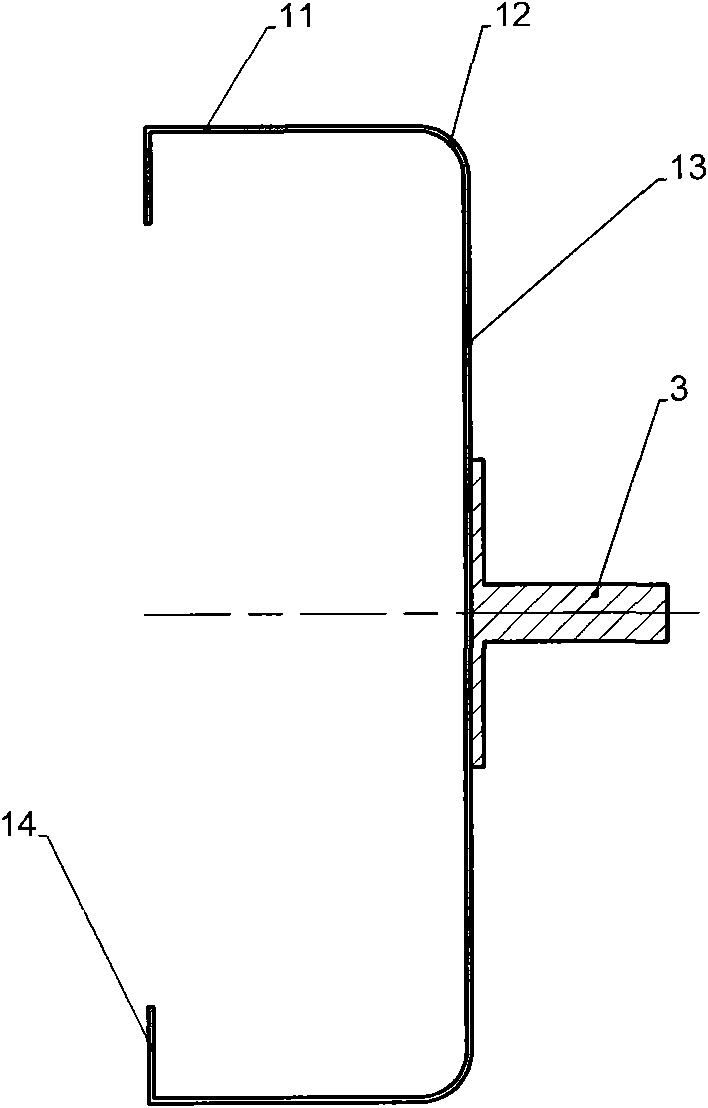

[0010] Such as figure 2 As s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com