Bio-enzyme corrosion inhibitor for circulating water system and application method thereof

A technology of circulating water system and corrosion inhibitor, which is applied in the field of environmental engineering, can solve the problems of excessive sewage discharge and downstream sewage treatment costs, increased fresh water consumption, and low water quality concentration ratio, so as to increase the corrosion inhibition effect and prevent corrosion. , easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

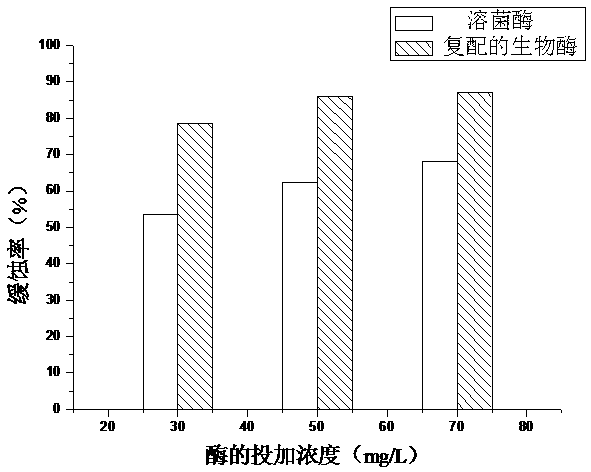

[0022] A biological enzyme corrosion inhibitor for slowing down the corrosion of carbon steel in a circulating water system consists of 1 part of lipase and 1.5 parts of lysozyme in terms of weight fraction. The activity of the lipase is >40000u / g; the activity of the lysozyme is >10000u / g.

[0023] A method for slowing down carbon steel corrosion in a circulating water system by using a biological enzyme corrosion inhibitor, comprising the following steps:

[0024] ① Weigh an appropriate amount of lipase and lysozyme and mix them evenly to obtain a biological enzyme corrosion inhibitor; the mass ratio of lipase and lysozyme in the biological enzyme corrosion inhibitor is 1:1.5;

[0025] ② dissolving the prepared biological enzyme corrosion inhibitor in water to obtain an aqueous solution of the biological enzyme corrosion inhibitor;

[0026] ③The experimental water was taken from the circulating water system of a refining and chemical enterprise in Qingdao. The concentration...

Embodiment 2

[0046] A biological enzyme corrosion inhibitor for slowing down the corrosion of carbon steel in a circulating water system consists of 1 part of lipase and 2 parts of lysozyme in terms of weight fraction. The activity of the lipase is >40000u / g; the activity of the lysozyme is >10000u / g.

[0047] A method for slowing down carbon steel corrosion in a circulating water system by using a biological enzyme corrosion inhibitor, comprising the following steps:

[0048] ① Weigh an appropriate amount of lipase and lysozyme and mix them evenly to obtain a biological enzyme corrosion inhibitor; the mass ratio of lipase and lysozyme in the biological enzyme corrosion inhibitor is 1:2;

[0049] ② dissolving the prepared biological enzyme corrosion inhibitor in water to obtain an aqueous solution of the biological enzyme corrosion inhibitor;

[0050] ③The experimental water was taken from the circulating water system of a refining and chemical enterprise in Qingdao. The concentration of ...

Embodiment 3

[0054] A biological enzyme corrosion inhibitor for slowing down the corrosion of carbon steel in a circulating water system consists of 1 part of lipase and 2.5 parts of lysozyme in terms of weight fraction. The activity of the lipase is >40000u / g; the activity of the lysozyme is >10000u / g.

[0055] A method for slowing down carbon steel corrosion in a circulating water system by using a biological enzyme corrosion inhibitor, comprising the following steps:

[0056] 1. Weigh an appropriate amount of lipase and lysozyme, and mix them uniformly to obtain a biological enzyme corrosion inhibitor; the mass ratio of lipase and lysozyme in the biological enzyme corrosion inhibitor is 1:2.5;

[0057] ② dissolving the prepared biological enzyme corrosion inhibitor in water to obtain an aqueous solution of the biological enzyme corrosion inhibitor;

[0058] ③The experimental water was taken from the circulating water system of a refining and chemical enterprise in Qingdao. The concentr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion rate | aaaaa | aaaaa |

| Corrosion rate | aaaaa | aaaaa |

| Corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com