Connecting structure for wide glue line

A technology for connecting structures and glue joints, applied in building components, building structures, walls, etc., can solve the problems of complex installation process, poor appearance, cracking glue joints, etc., and achieve good thermal insulation effect, convenient installation, and improved thermal insulation performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

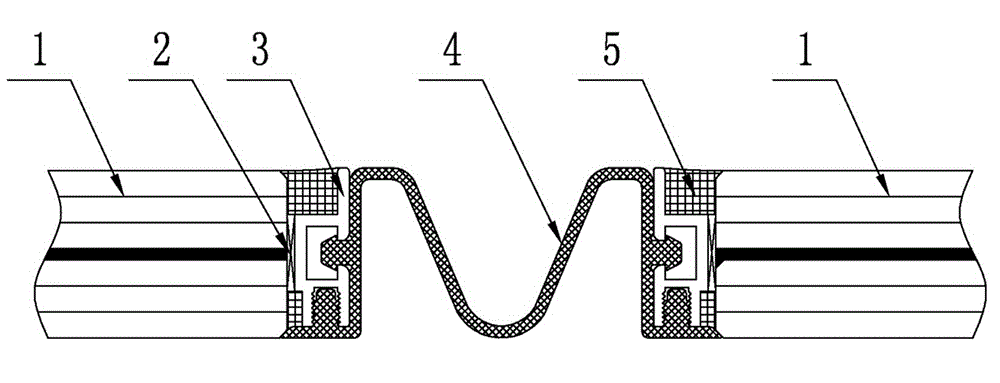

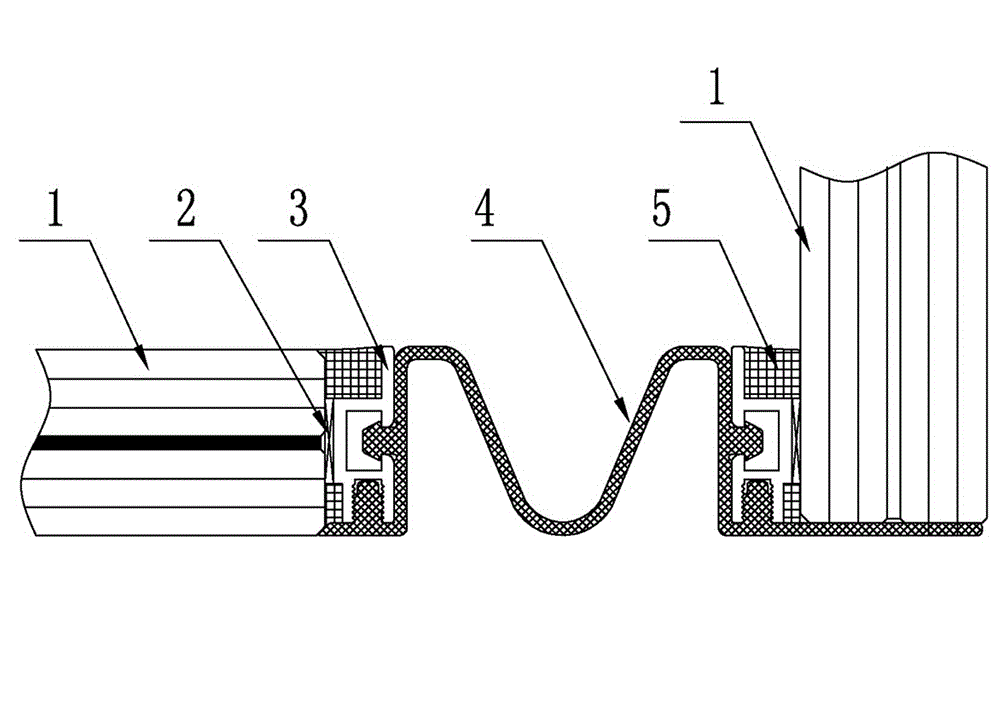

[0016] Combine below figure 1 and figure 2 The present invention is described in further detail. The wide glue seam connection structure includes a surface material 1, a metal profile 3 fixed on the surface material, an elastic pad 2 arranged between them, a structural glue 5 connecting the surface material 1 and the metal profile 3, and the most important Organ tape4. Among them, the organ rubber strip 4 has a long outer edge protection, and the metal profile 3 has a rubber strip notch and is connected to the surface material 1 through the structural glue 5. There is an elastic pad 2 between the metal profile 3 and the surface material 1, and the organ glue The strip 4 is pressed into the strip notch of the metal profile 3, and the long outer edge of the organ strip 4 covers the metal profile 3, and the long edge of the organ strip 4 is closely attached to the surface material 1 at the corner of the curtain wall. At the edge of the cross glue joint, the organ rubber strip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com