Downhole motor

An engine and power technology, which is applied in the direction of engine components, machines/engines, and driving devices for drilling in boreholes, can solve problems such as limiting the scope of use, increasing drilling risks, and delaying drilling cycles, so as to speed up exploration and shorten the drilling time. The effect of improving the well construction period and increasing the drilling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in a variety of different ways defined and covered by the claims.

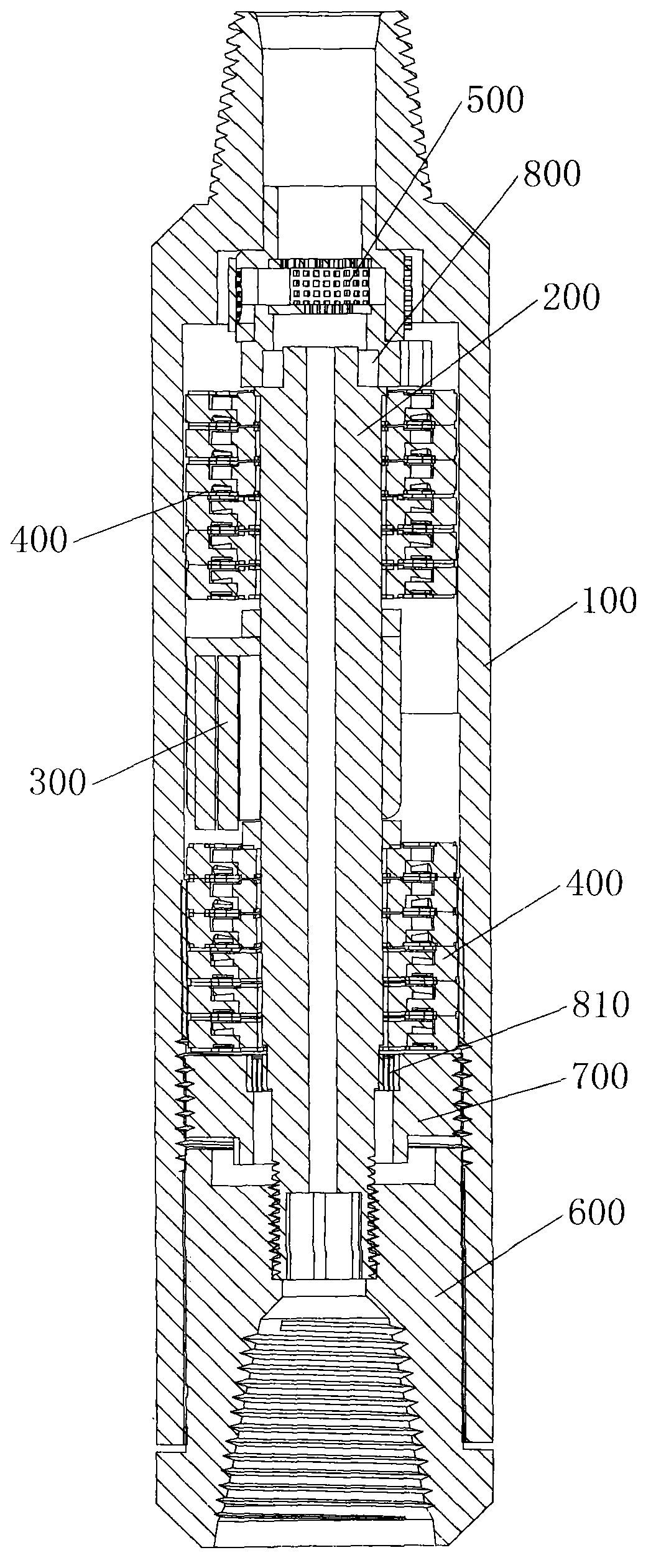

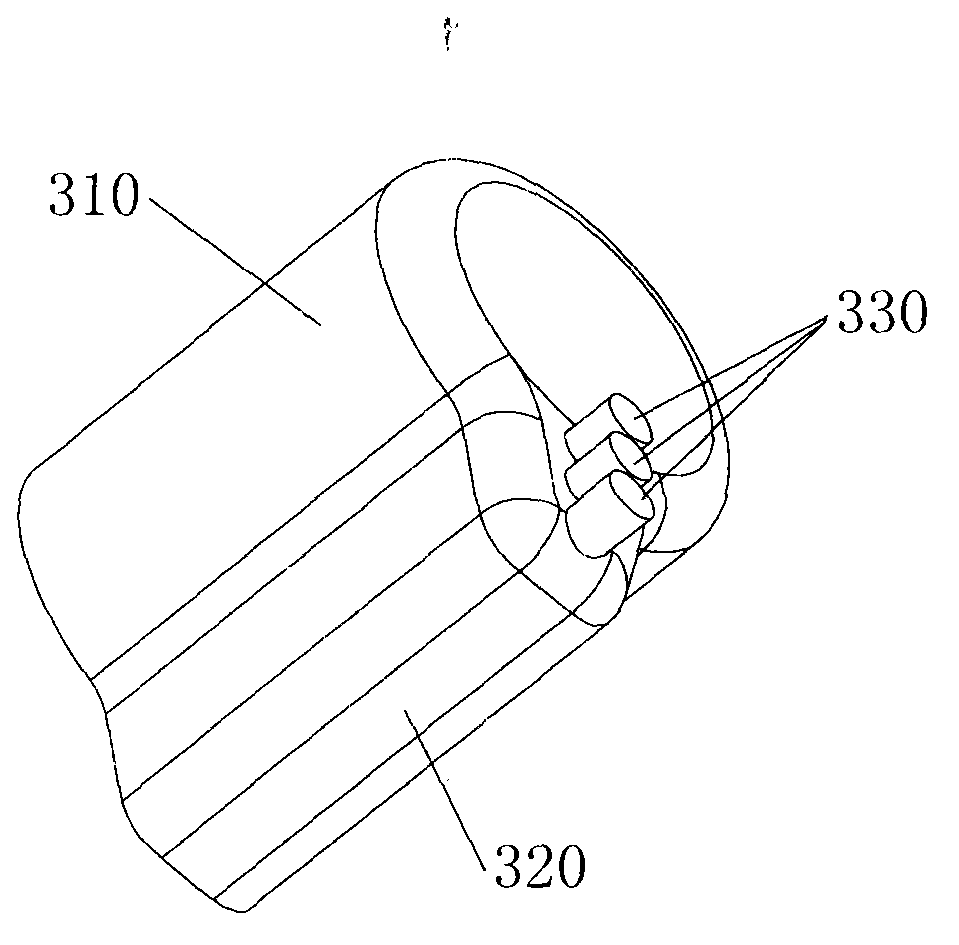

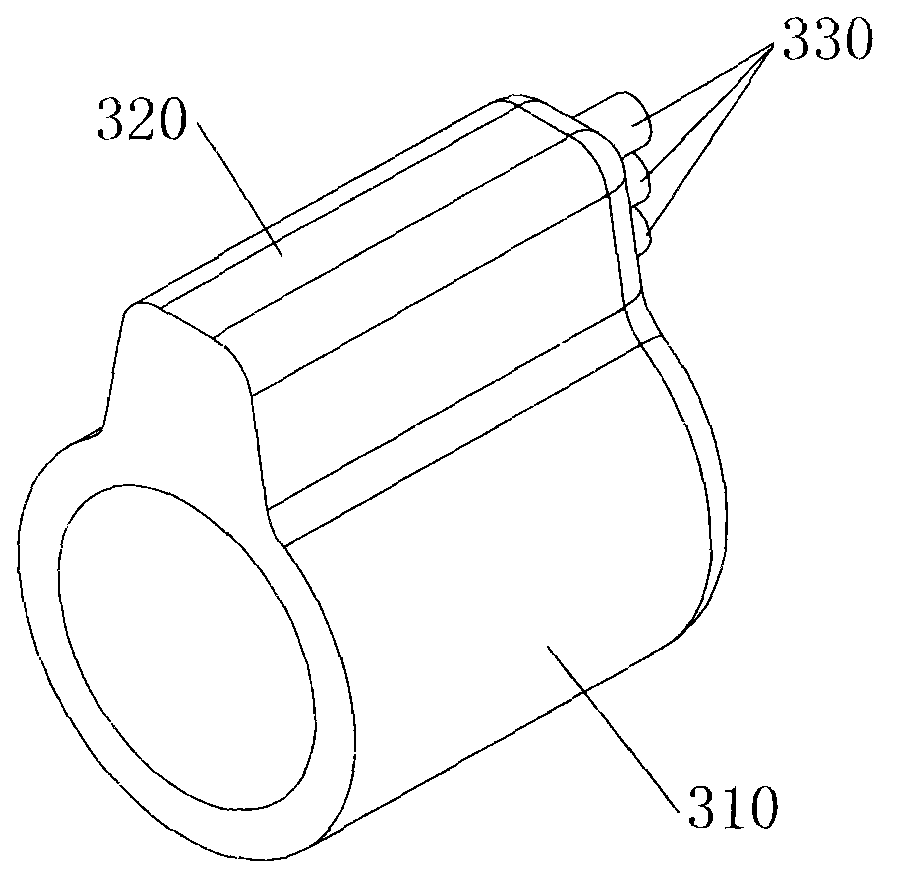

[0041] Such as figure 1 As shown, the bottom hole engine in the present invention includes: a housing 100; a mandrel 200, the mandrel 200 is pivotally installed in the housing 100; a power eccentric hammer 300, the power eccentric hammer 300 is installed on the mandrel 200; and At least one turbine assembly 400 is installed in the casing 100, and the mandrel 200 passes through the turbine assembly 400. Preferably, the number of the turbine assembly 400 is two, and the two turbine assemblies 400 are respectively provided with the upper and lower sides of the power eccentric hammer 300.

[0042] After the mud enters the upper inlet of the casing 100, it flows through the upper turbine assembly 400, the power eccentric hammer 300 and the lower turbi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com