Oil well pump

A technology for oil well pumps and pump barrels, which is applied in the field of oil well pumps controlled by double valves. It can solve the problems of steam lock, opening and closing delay of oil well pumps with fixed valve balls, low pump efficiency and mechanical recovery efficiency of heavy oil, and improve pump efficiency. and mechanical mining efficiency, and solve the effect of opening and closing lag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

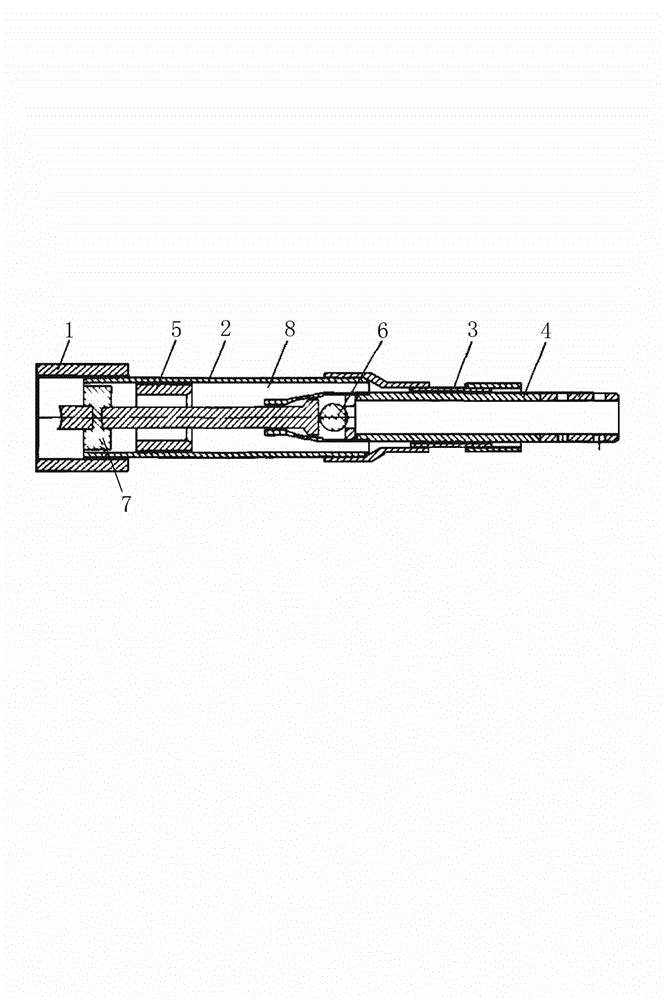

[0008] An oil well pump according to the present invention comprises a pump head 1, a pump barrel 2 and a plunger barrel 3, the pump head 1 is fixedly arranged at one end of the pump barrel 2, and the plunger barrel 3 is fixedly arranged at the other end of the pump barrel 2, And a part of the plunger barrel 3 extends to the inside of the pump barrel 2, the plunger rod 4 is movably arranged inside the plunger barrel 3, and the inside of the pump barrel 2 is also fixedly provided with a floating valve body 5, and the floating valve body 5 is set Between the plunger barrel 3 and the pump head 1, it is characterized in that the plunger rod 4 extends from the inside of the plunger barrel 3 to the inside of the pump barrel 2 and passes through the floating valve body 5. On the plunger rod 4 A fixed valve 6 and a floating valve cover 7 are respectively provided, the floating valve cover 7 is matched with the floating valve body 5, and the fixed valve 6 is arranged inside the plunger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com