Parking mechanism and control method applied to automated mechanical transmission (AMT)

A transmission control and parking mechanism technology, applied in the direction of transmission control, mechanical equipment, components with teeth, etc., can solve the problems of no gear shifting mechanism, no P gear parking function, etc., to achieve convenient control and easy Manufacturing, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Further illustrate structure of the present invention below in conjunction with accompanying drawing:

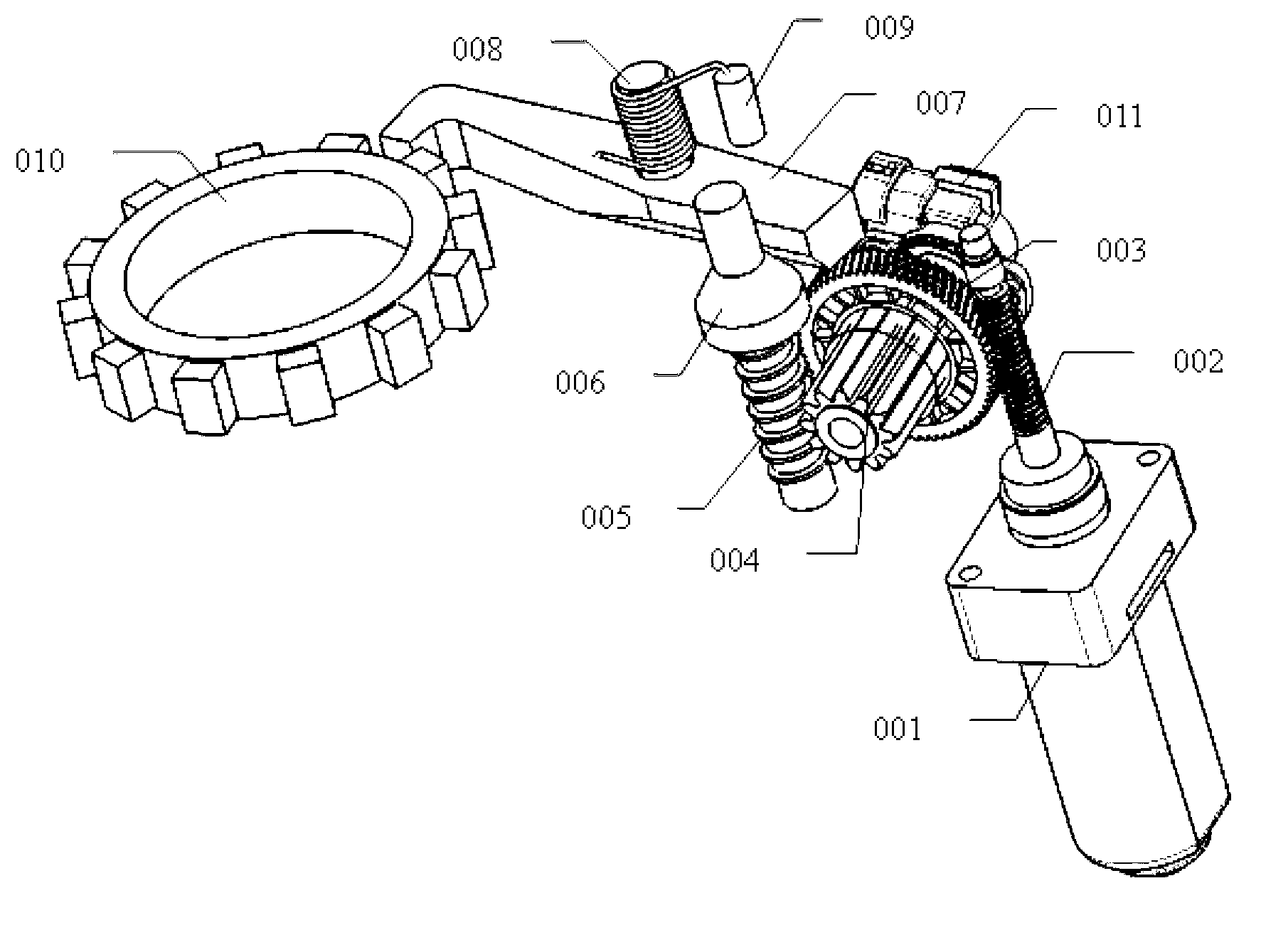

[0025] Such as figure 1 As shown, the P gear mechanical actuator provided by the present invention includes a parking motor 001 outside the transmission case, a worm gear assembly inside the transmission case, a gear 004, a screw 005, a parking ratchet 010 and a parking ratchet Claw 007.

[0026] The worm gear assembly consists of a worm 002 and a worm gear 003 on the worm shaft. One end of the worm shaft protrudes from the transmission case and is connected to the P gear sensor 011. The signal is transmitted to the TCU to determine the position of the P gear cam, so as to decide when to send a working signal to the parking motor, and realize the control of the P gear in turn. The parking motor is connected with the worm, and the worm is meshed with the worm gear.

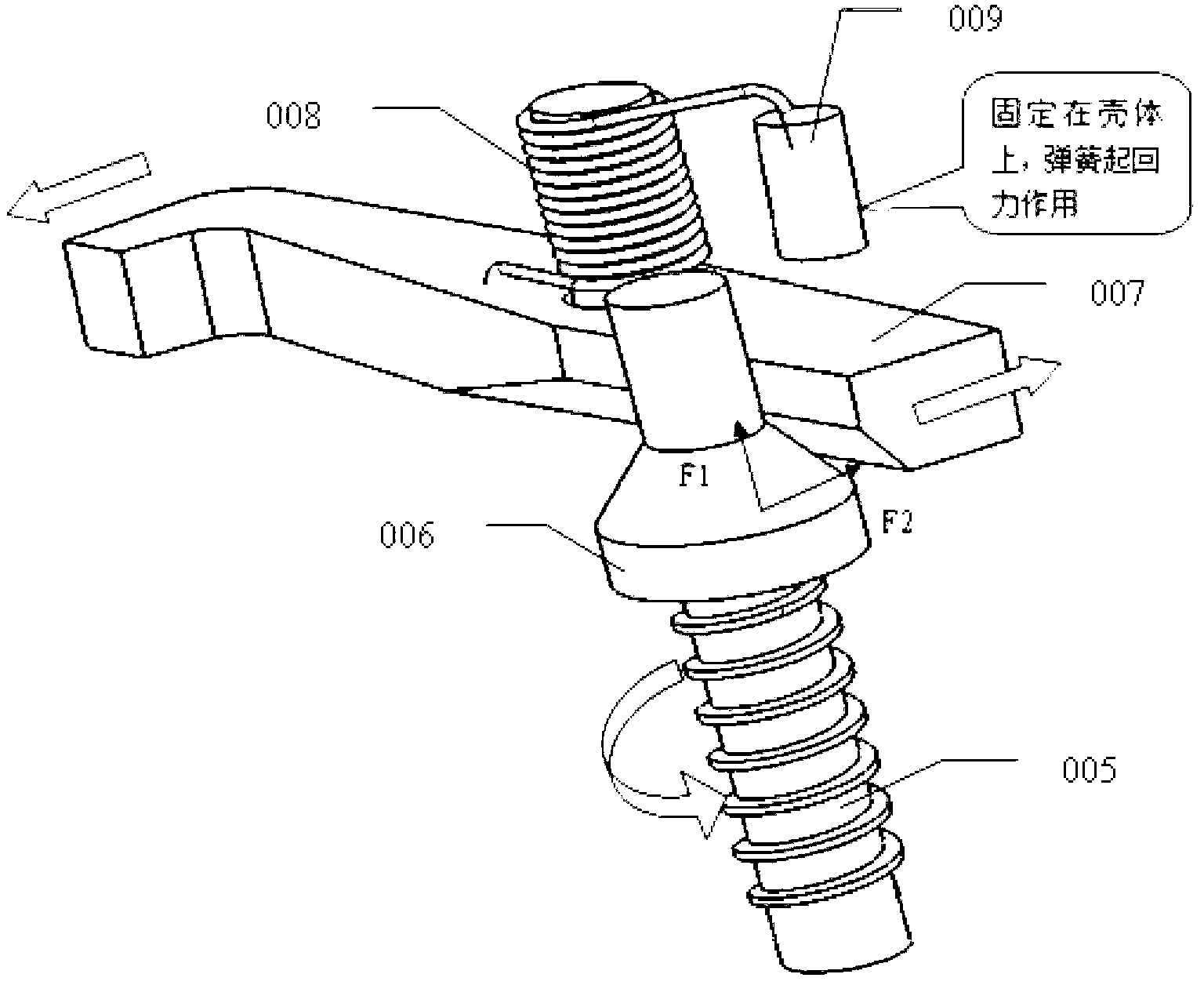

[0027] A gear 004 is coaxially installed on the worm shaft, which meshes with the screw 005. The up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com