Urban gas buried pipeline leakage detection and locating method and applications thereof

A buried pipeline and leakage detection technology, which is applied in the pipeline system, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of sensitivity affected by noise, difficult leakage sources, research and testing, etc., so as to avoid artificial Subjective judgment, high sensitivity, and the effect of saving detection costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0054] Instance 1 basic data

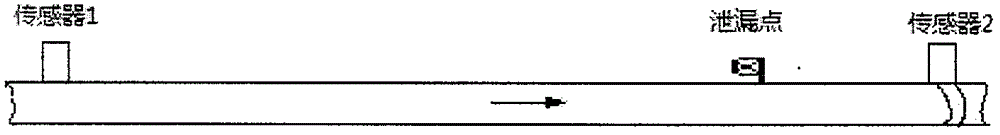

[0055] Pipe section 1 is located on Xinmin Road, Changzhou City. The pipe length is about 67.5m. It is a medium-pressure grade B cast iron pipe with a pipe pressure of about 45KPa and a pipe diameter of about 426mm. There are many joints, sleeves, valves and other connection ports on this pipe section, such as Image 6 As shown, No. 1 sensor is arranged on the tee at one end of the pipe section, No. 2 sensor is arranged on the valve at the other end, and the distance between the two sensors is 67.5m. It can be seen from the pipeline design layout that the positions 5m, 11m, 17m, 23m, 29m, 35m, 41m, 47m, 53m, 55.6m, and 61.6m away from No. 1 sensor are all the joints of pipes.

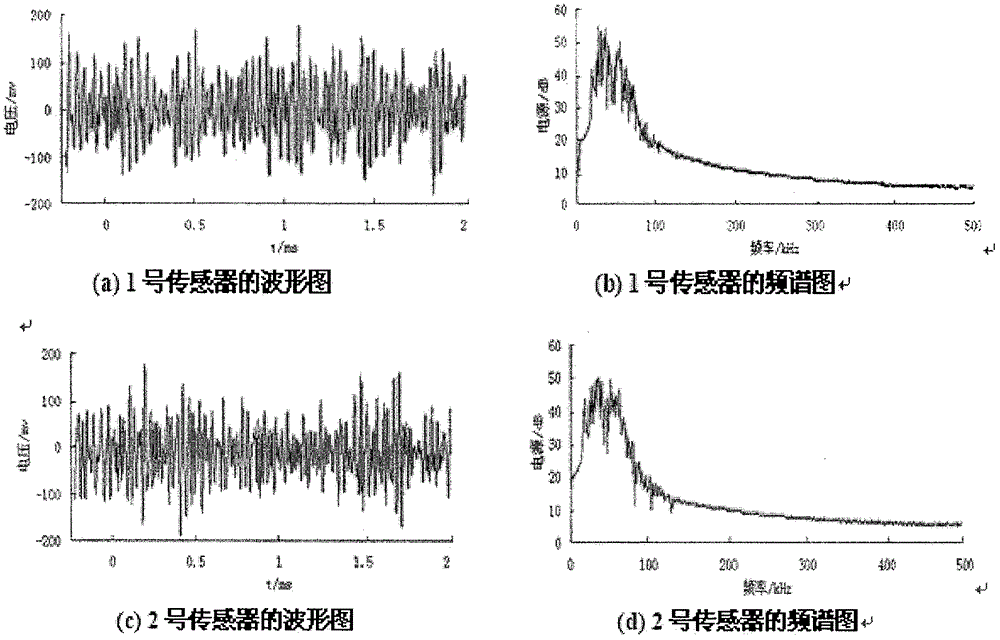

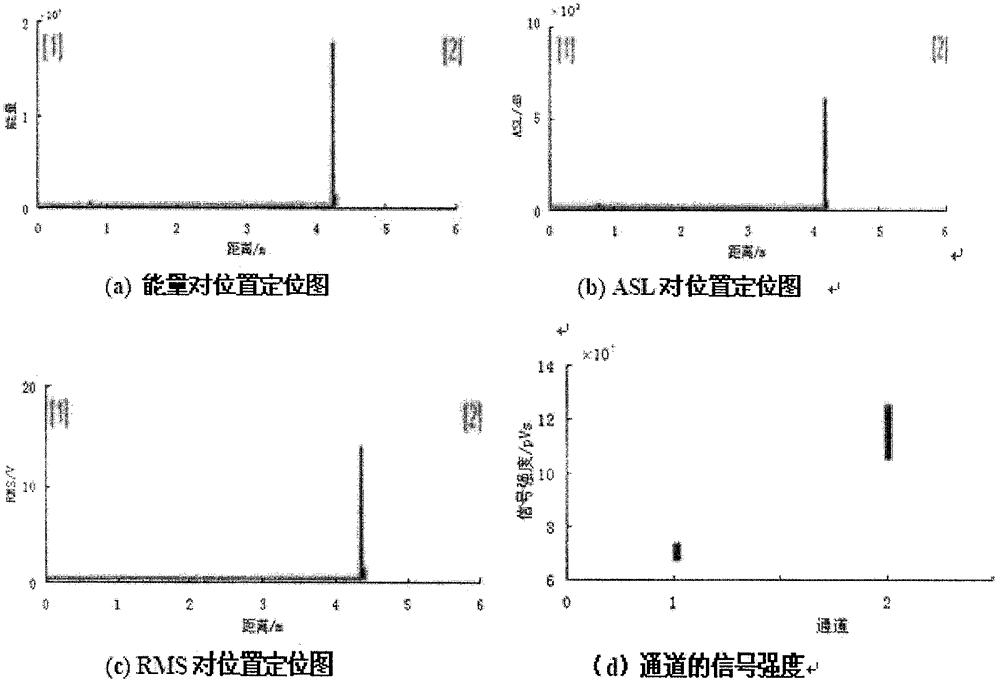

[0056] After testing, input suitable parameters such as the threshold system, and collected 3 sets of data, one of which is a set of positioning maps such as Figure 7 a, b, c, d.

[0057] From the positioning map, it is roughly judged that the leakage signal is more ob...

example 2

[0062] Instance 2 basic data

[0063] Pipe section 2 is located on Xinfeng Street, with a pipe length of about 84m, a medium-pressure grade B cast iron pipe, and a pipe diameter of about 426mm. There are many joints, sleeves, valves and other connection ports on this pipe section, such as Figure 9 As shown, No. 1 and No. 2 sensors are respectively arranged on the valves at both ends of the pipe section, and the distance between the two sensors is 84m.

[0064] It can be seen from the pipeline design layout that there is a sleeve at a distance of 0.8m from No. 1 sensor, two S-bends at 1.2m and 6.9m from No. m, 29.5m, 35.5m, 41.5m, 47.5m, 53.5m, 59.5m, 65.5m, 71.5m, and 77.5m are the plugs between pipes, sometimes with a long service life, and these parts may leak .

[0065] Three sets of test data were also collected. One set of positioning diagrams for each channel is shown in Figure 10 a, b, c, d.

[0066] From the positioning map, it can be roughly judged that there ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com