a burner

A burner and combustion device technology, applied in the direction of burners, burners, gas fuel burners, etc., can solve the problems of incomplete combustion, poor combustion effect, high carbon monoxide concentration, etc., achieve sufficient mixing, reduce emission rate, and improve combustion efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

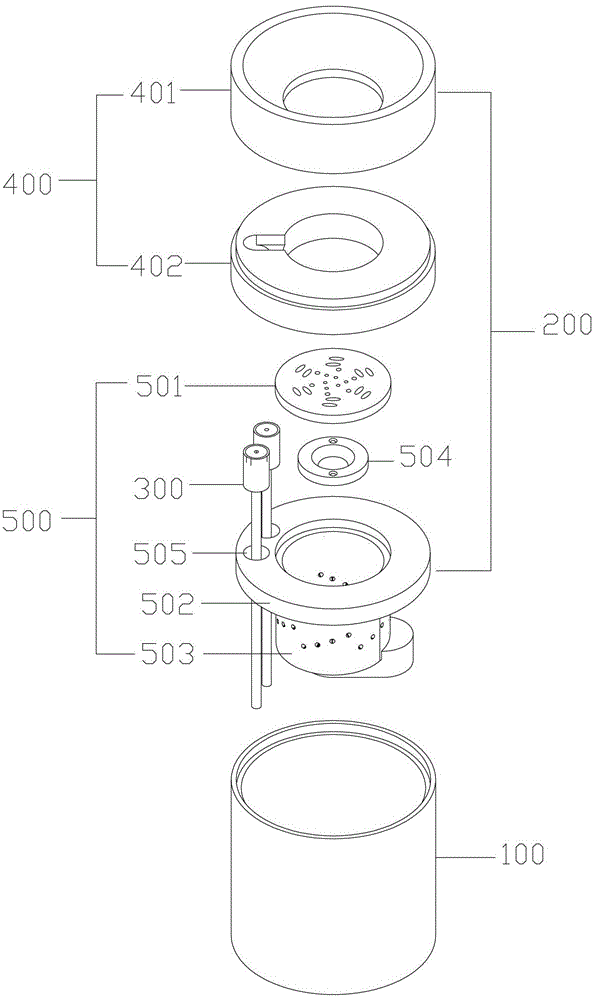

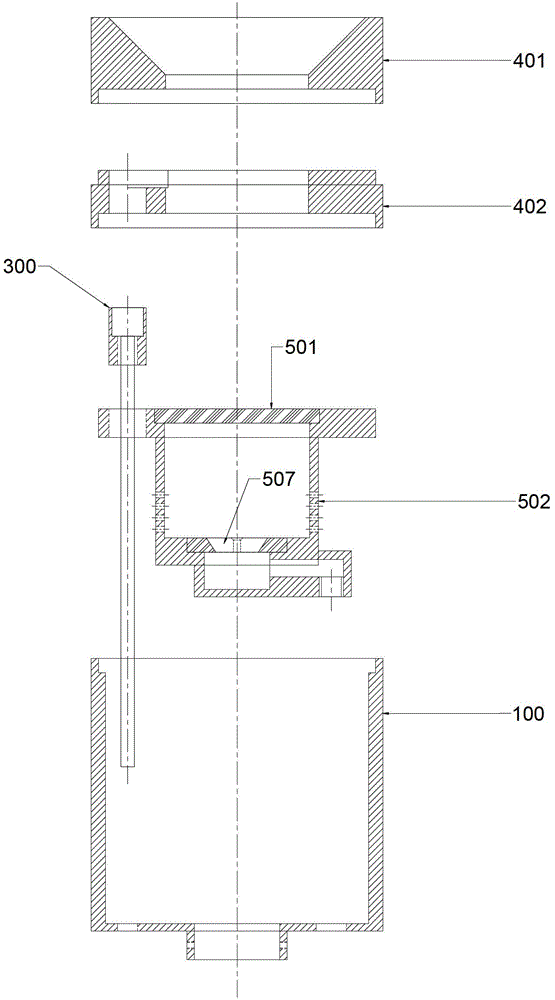

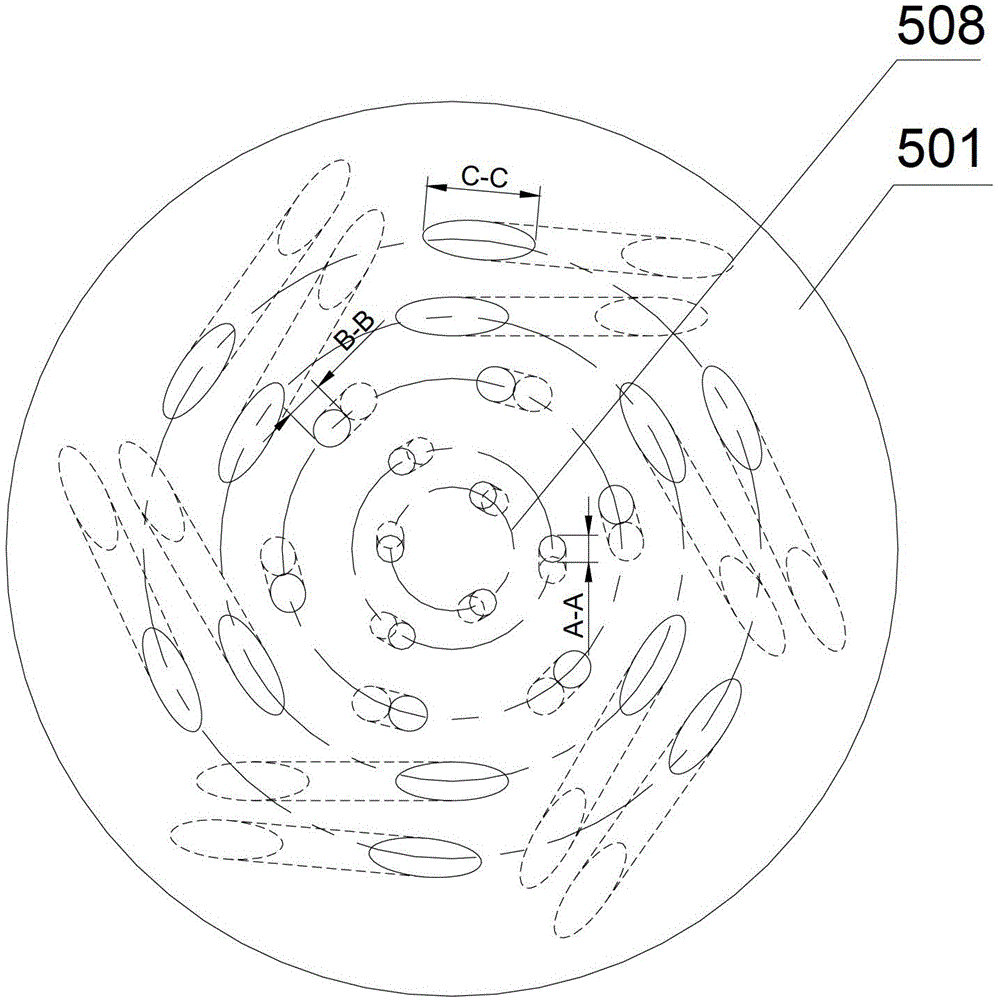

[0024] like Figure 1-2 As shown, in a preferred embodiment of the present invention, the burner includes a casing 100, and a furnace body 200 disposed in the casing, the furnace body 200 further includes an igniter 300, a combustion device 400 and an air-gas mixing device 500, air and gas The gas is mixed in the air-gas mixing device 500 , the mixed gas enters the combustion device 400 , and then is ignited by the igniter 300 to burn the mixed gas. In the present invention, a flame-stabilizing pad 501 for controlling the release of the mixture of air and gas is also provided between the combustion device 400 and the air-gas mixing device 500 . like image 3 As shown, the flame-stabilizing pad 501 is provided with multiple sets of air-gas passages 508 surrounding the center of the flame-stabilizing pad 501 (only one set of air-gas passages are marked in the figure), for the sake of distinction, in image 3 Each group of air and gas passages is marked with dotted lines, and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com