Tungsten filament rope coiling machine charge coupled device (CCD) image capture display method and detecting device thereof

A technology of magnified display and detection device, which is applied in the direction of optical testing for flaws/defects, and can solve problems such as tungsten wire rope monitoring and achieve the effect of convenient observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

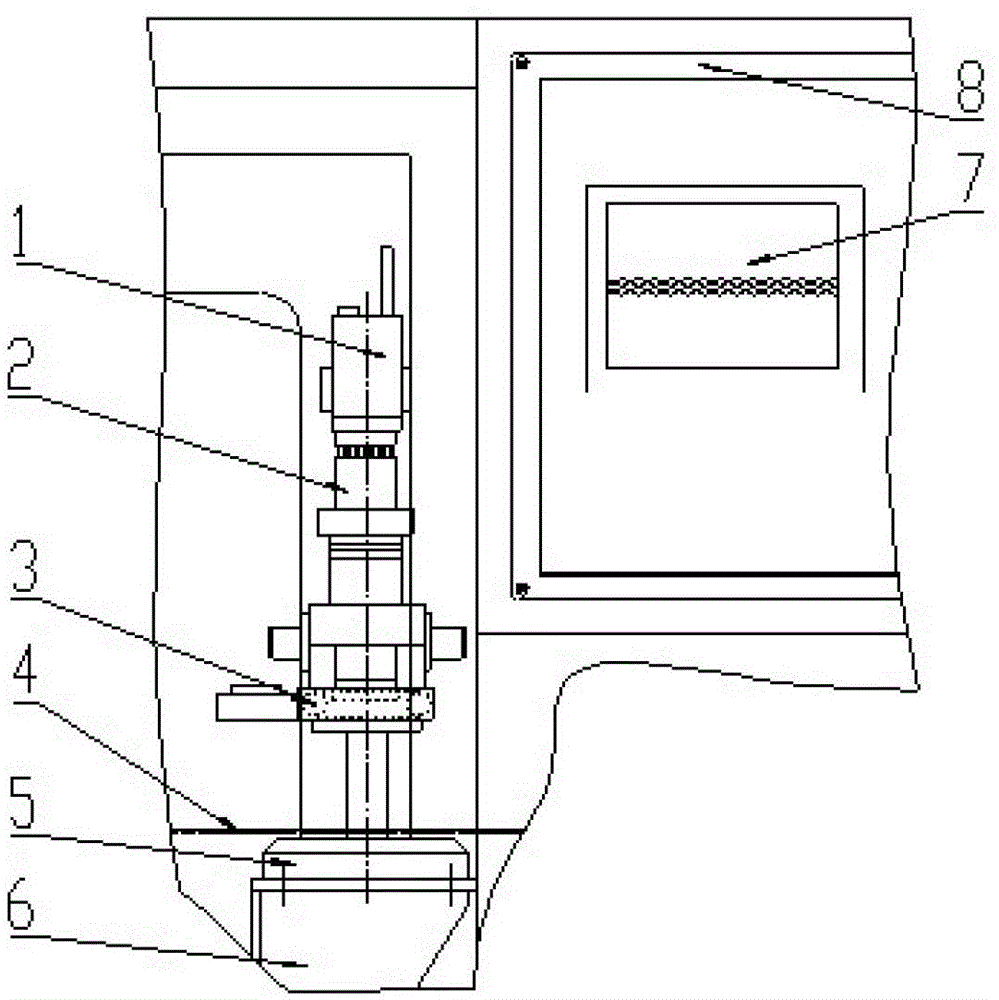

[0010] In order to observe and inspect the winding state of the fine tungsten wire rope (or strand) better, the present invention adopts a CCD image-taking enlargement display detection device in the tungsten wire rope winding machine equipment. Its principle is to image the monitored work piece and enlarge it with a precision microscope. The image is placed on the CCD chip, and the CCD processes the image into electrical information and sends it to the display processing system, which is enlarged and displayed on the display surface.

[0011] As shown in the figure, the CCD magnification display detection device is fixedly connected with the seat 6 on the tungsten wire rope winding machine through the microscope base 5 . The light source 3 directly shines on the tungsten wire rope 4 to make the camera clearer. The microscope 2 captures and enlarges the tungsten wire rope 4, and its image is placed on the CCD1 chip, and the image is processed into electrical information and se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com