Capacitance type wind speed and wind direction transducer

A wind speed, direction and sensor technology, applied in instruments, fluid velocity measurement, velocity/acceleration/impact measurement, etc., can solve the problems of easy wear, large size, and high price, and achieve low temperature drift, low cost, and low power consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

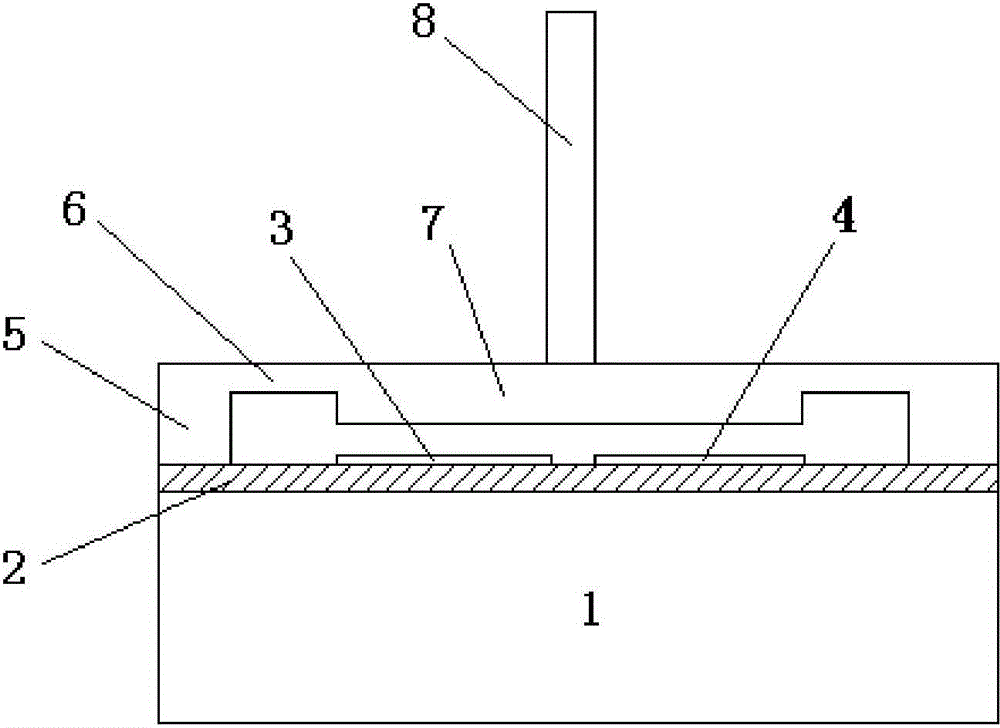

[0012] Below in conjunction with accompanying drawing, the present invention will be further described.

[0013] The small capacitive wind speed and direction sensor proposed by the invention uses the capacitance principle to measure wind speed and wind direction. It includes a substrate 1, an insulator 2 arranged on the surface of the substrate 1, a first capacitor bottom electrode 3 and a second capacitor bottom electrode 4 respectively arranged on the surface of the insulator 2 and separated by a certain distance, and a support anchor area connected to the insulator 2 5. The elastic membrane 6 connected to the support anchor area 5, the rigid thin plate 7 connected to the elastic membrane 6, and the wind rod 8 arranged on the rigid thin plate 7,

[0014] The wind pole 8 is located at the center of the rigid sheet 7, the first capacitor bottom electrode 3 and the second capacitor bottom electrode 4 are symmetrically placed relative to the center of the rigid sheet 7, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com