Power matching controlling simulation testing system of automobile crane

A truck crane, simulation test technology, applied in general control system, control/adjustment system, electrical test/monitoring, etc., can solve problems such as safety accidents, central controller installation, construction machinery equipment damage, etc., so as not to waste energy , easy debugging, and cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

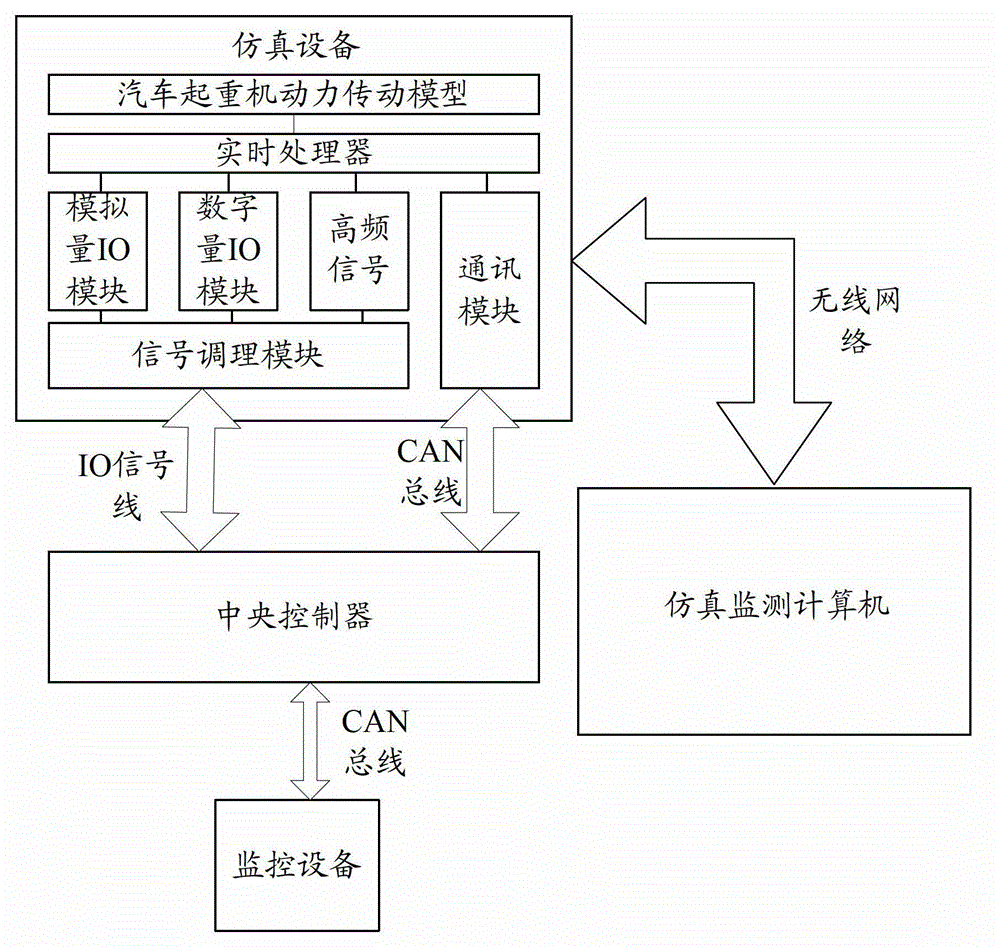

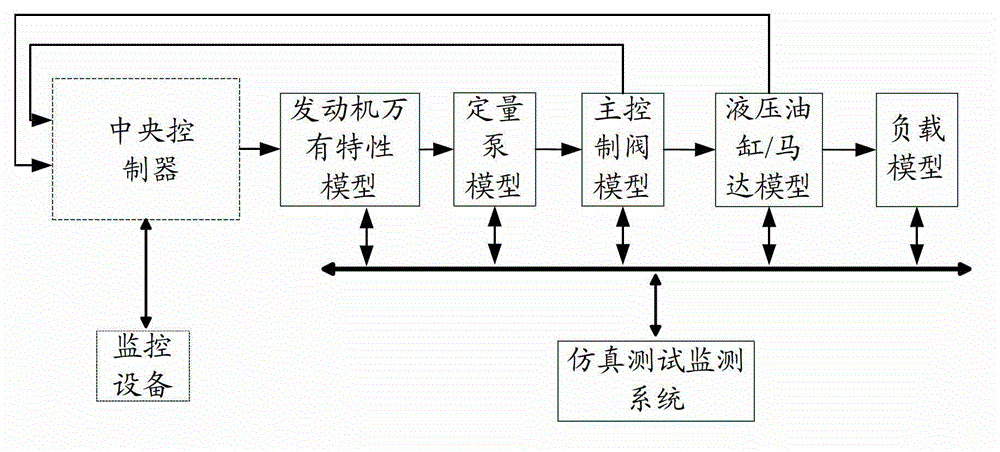

[0022] Please also refer to figure 1 and figure 2 The power matching control simulation test system of the truck crane of the present invention includes simulation equipment, simulation monitoring computer, central controller and monitoring equipment.

[0023] The simulation device simulates the powertrain of the truck crane and produces output information. The power transmission system of the truck crane includes the engine, the metering pump, the main control valve, the hydraulic cylinder and the hydraulic motor. The engine drives the quantitative pump to output hydraulic oil, and the hydraulic oil reaches the hydraulic cylinder or hydraulic motor through the main control valve to drive the load.

[0024] The simulation equipment specifically includes the power transmission model of the truck crane, a real-time processor, an analog IO (Input-Output, input-output) module, a digital IO module, a high-frequency signal module, a communication module and a signal conditioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com