Super capacitor and manufacturing technique of super capacitor

A technology of supercapacitor and production process, which is applied in the manufacture of hybrid/electric double layer capacitors, hybrid box/shell/package, etc. It can improve the sealing performance and working stability, improve the safety and stability of use, and reduce the scrap rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

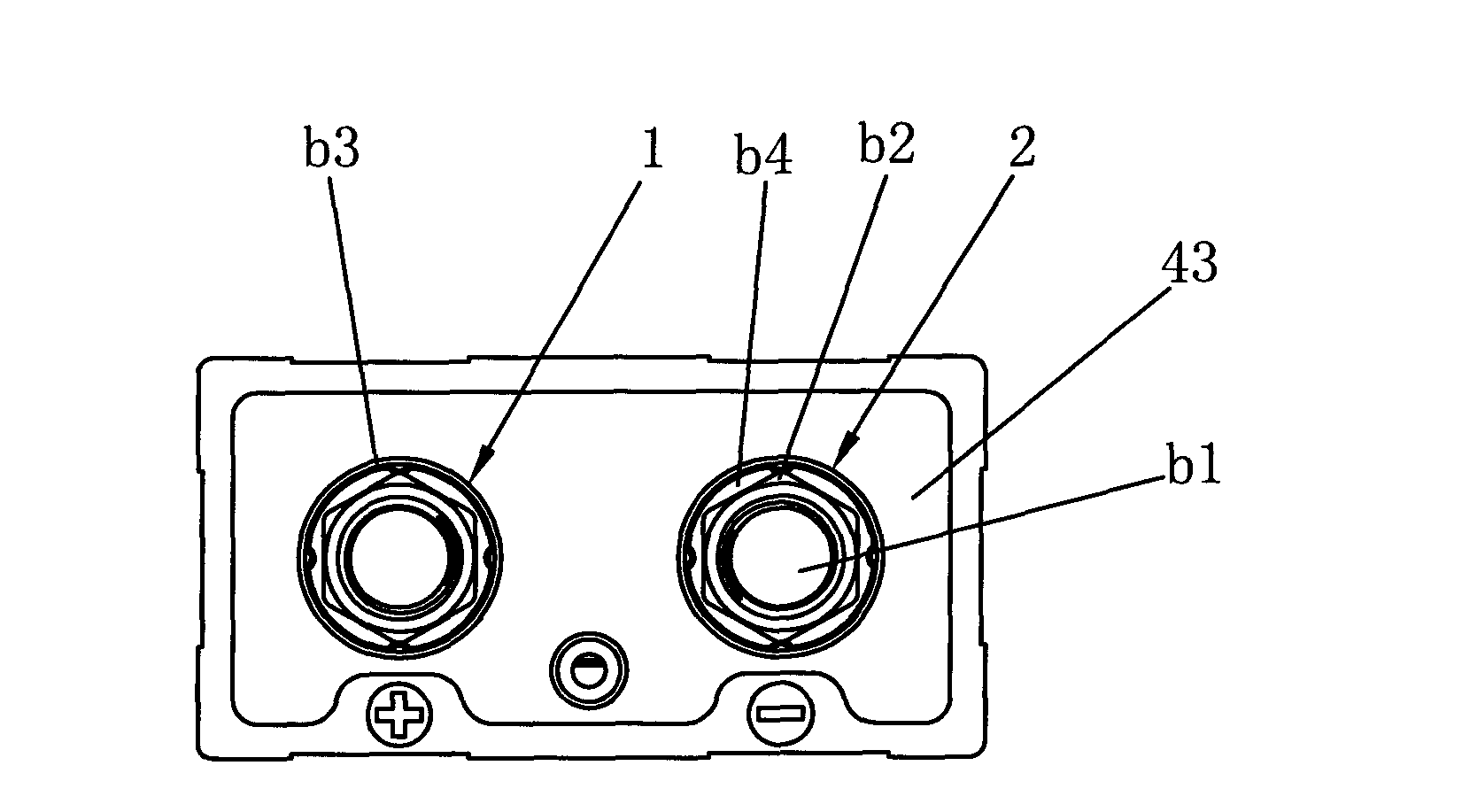

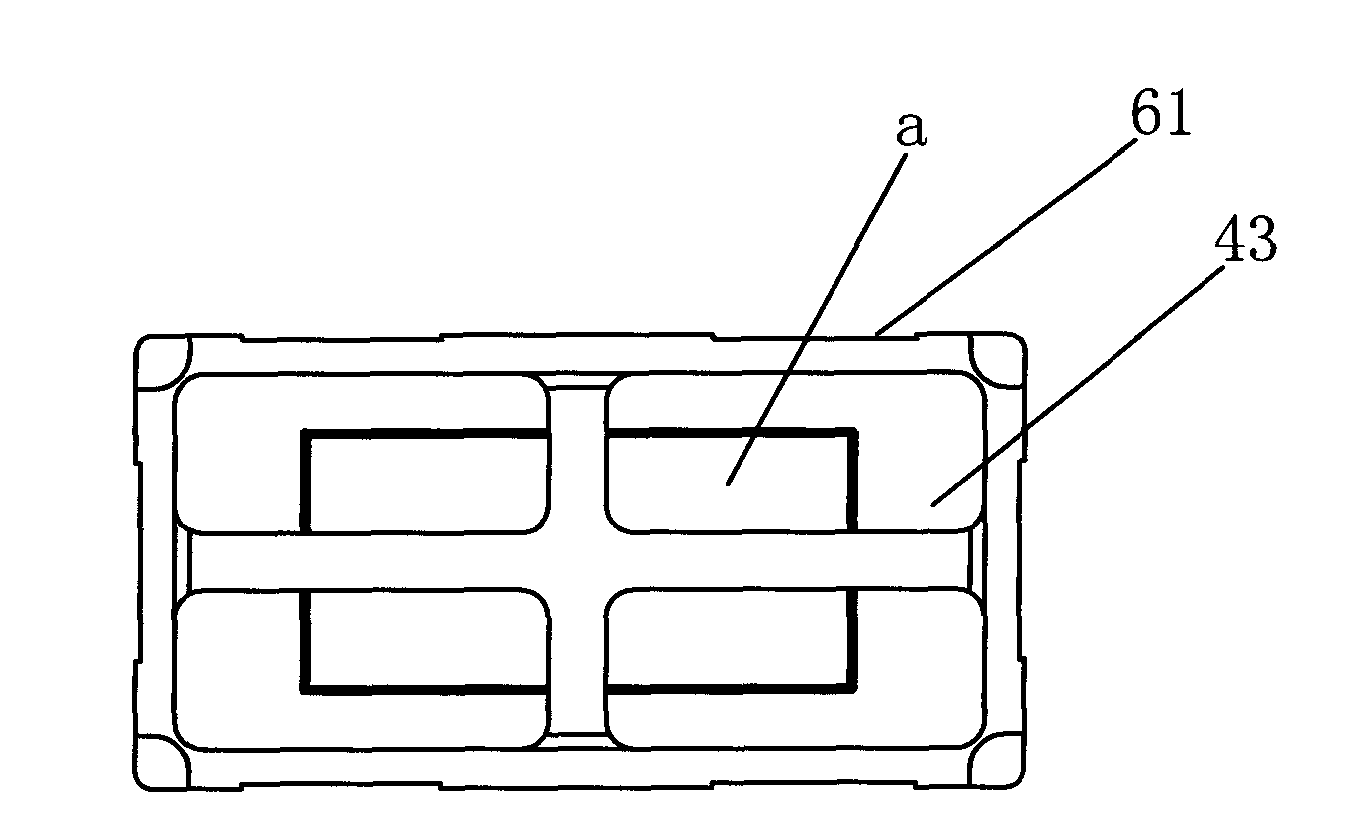

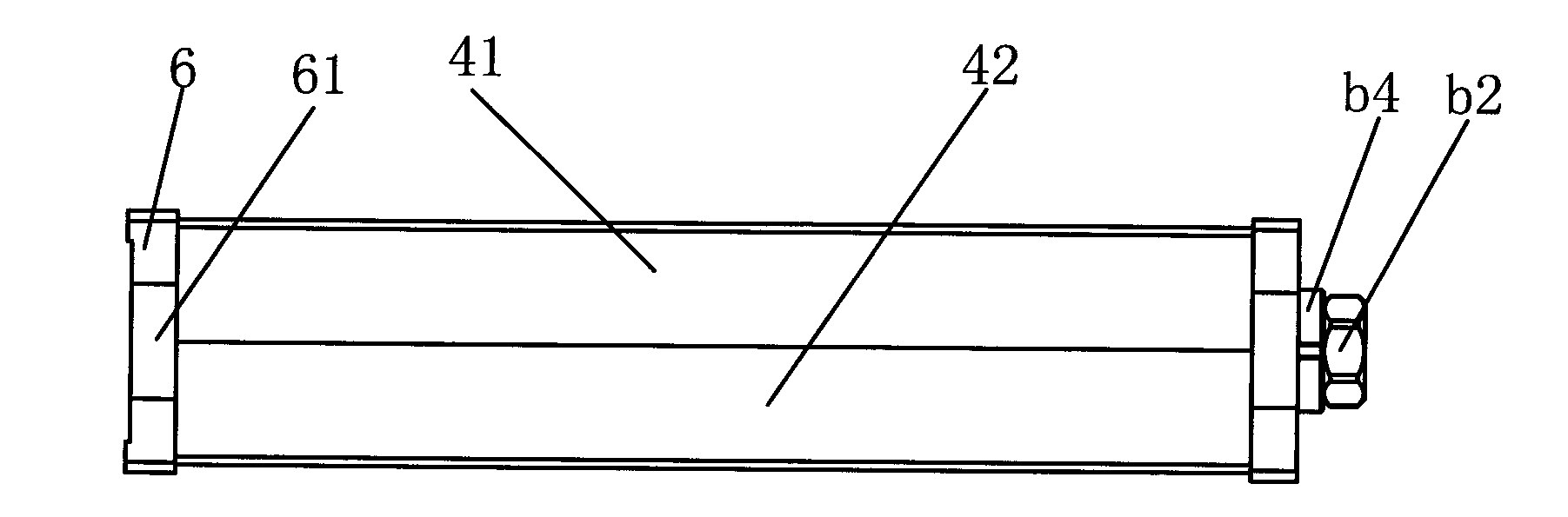

[0042] Such as Figure 1-11 As shown, the specific embodiment of the present invention is a supercapacitor and its production process, including a positive terminal 1, a negative terminal 2, a capacitor module 3 and a casing 4, the capacitor module 3 is arranged in the casing 4, and the positive terminal 1 The negative terminal 2 is fixedly arranged at one end of the housing 4 and connected to the capacitor module 3 inside the housing 4. The housing 4 adopts a split design, including an upper housing 41, a lower housing 42, a front cover 43 and a rear housing made of stainless steel materials. The cover plate 44, the upper case 41, the lower case 42, the front cover 43 and the rear cover 44 are tightly connected to form an inner cavity, and the capacitor module 3 is adapted to be arranged in the inner cavity, and the capacitor module 3 The outer surface is provided with PC paper p, the positive terminal 1 and the negative terminal 2 are fitted on the front cover 43 and pass th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com