Square-cylindrical-surface solid-core microchannel plate preparation method and square-cylindrical-surface solid-core microchannel plate

A technology of microchannel plate and square column, which is applied in cold cathode manufacturing, electrode system manufacturing, discharge tube/lamp manufacturing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

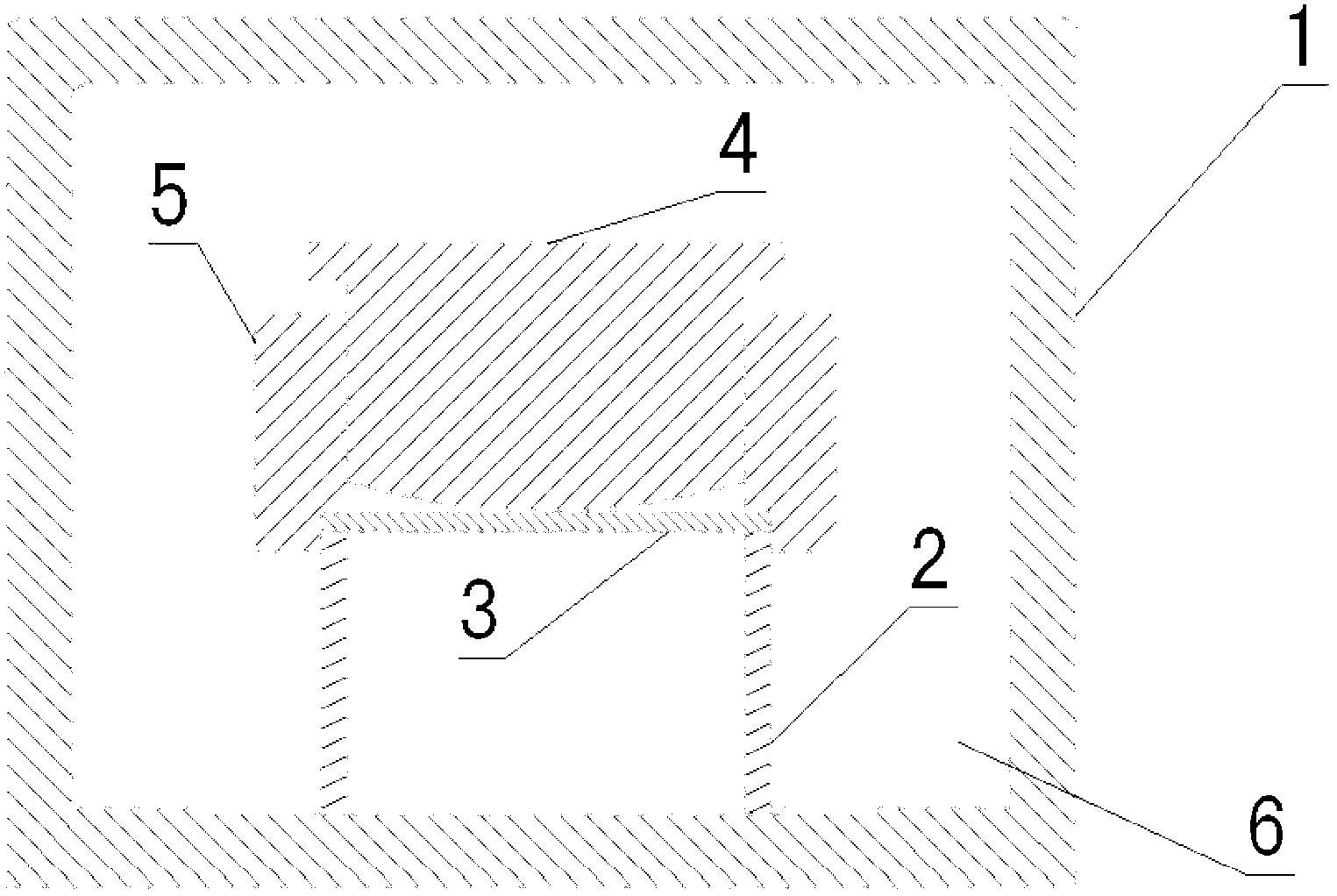

[0024] Step 1: Establish a square planar solid-core microchannel plate preparation device.

[0025] according to figure 1 The structure shown is implemented, wherein the vacuum heating furnace 1 is a square high-temperature molybdenum sheet heating furnace with a power of tens of kW, except that molybdenum sheets are not installed on its lower inner surface, and molybdenum sheets are installed on the other five inner surfaces. A door is installed on one side, and there are five layers of stainless steel screens on the outside of the molybdenum sheet as a heat insulation layer. The internal heating space of the vacuum heating furnace 1 is 300mm×300mm×300mm, and the space of the uniform temperature zone is 200mm×200mm×200mm. The inner temperature uniformity is ±2°C, the temperature control accuracy is ±1°C, the temperature range of the uniform temperature zone is from room temperature to 1000°C, the square support frame 2 is a square tube made of stainless steel, and the width o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com