Storage battery plate wrapping machine

A battery and wrapping machine technology, applied in the field of batteries, can solve problems such as increased workload of workers, waste of resources, and increased production costs of batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

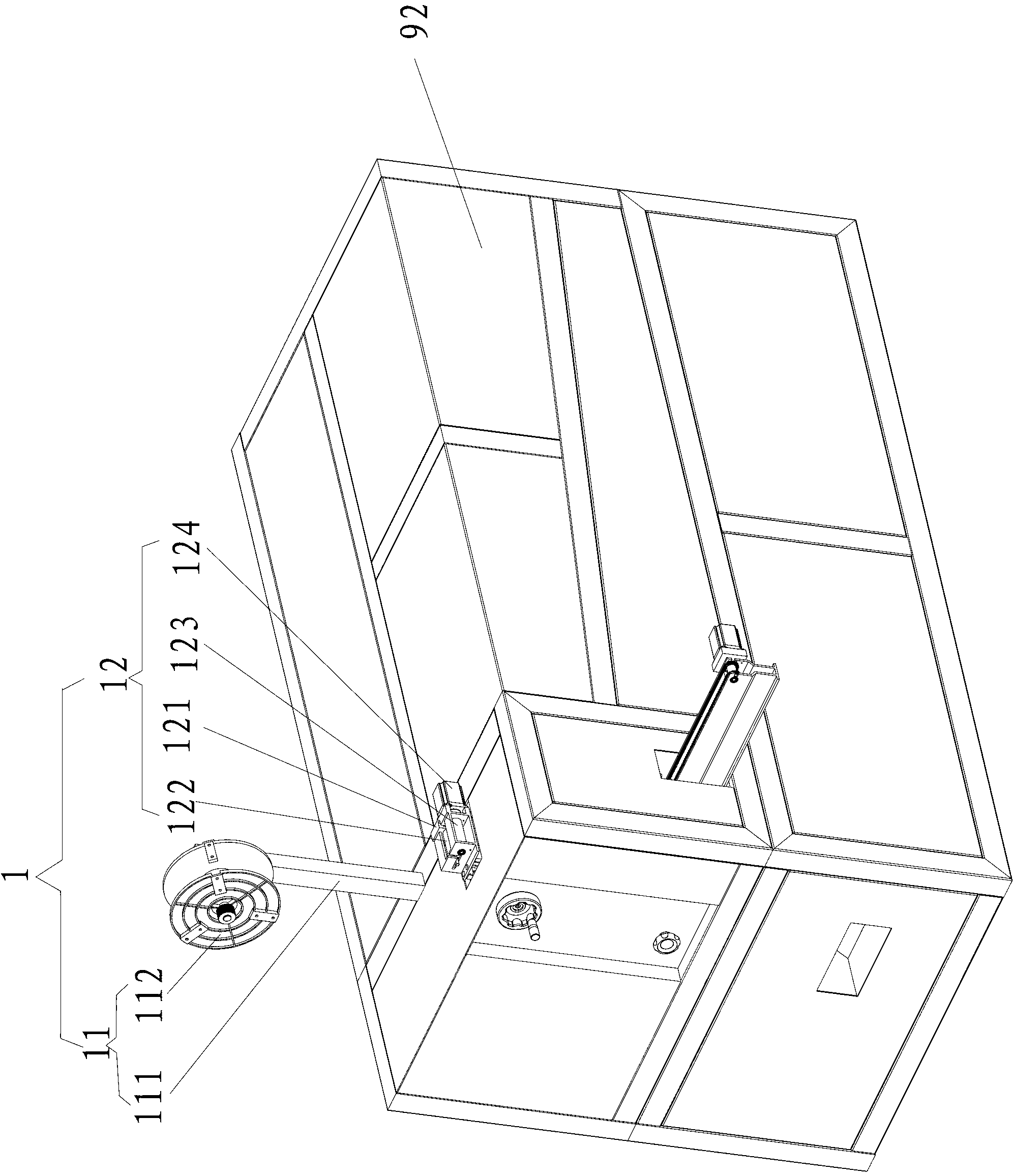

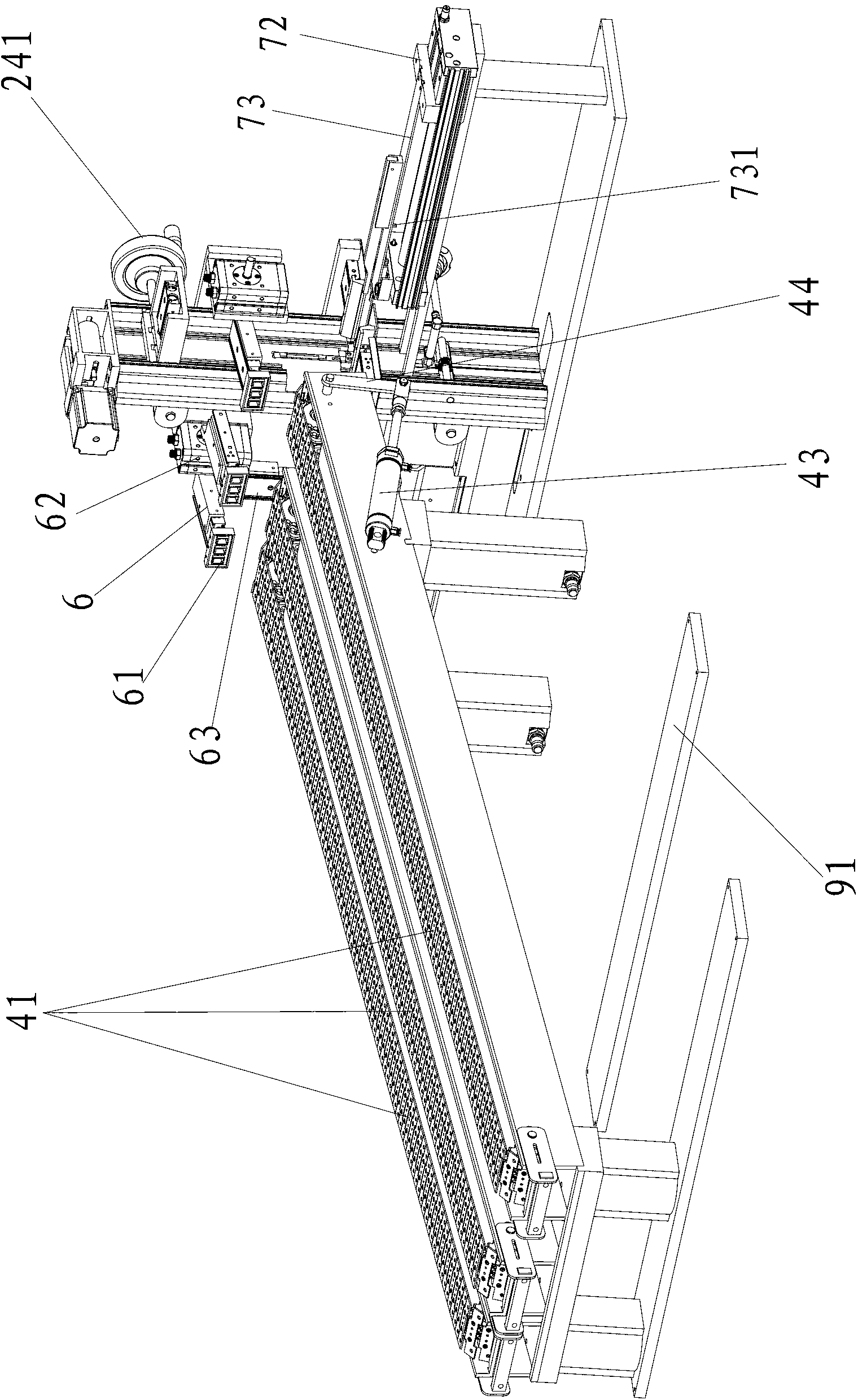

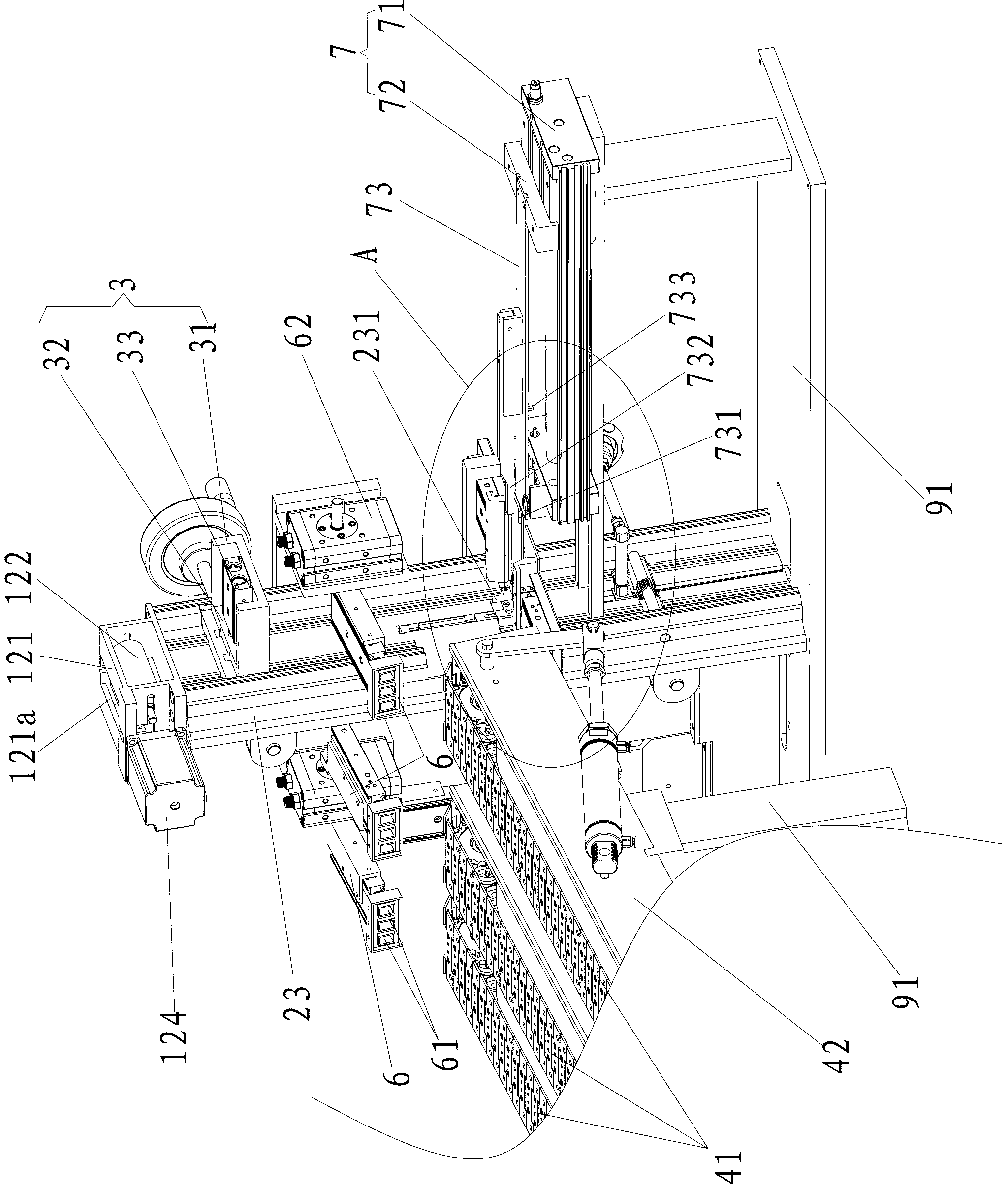

[0027] The accumulator polar plate wrapping machine of the present invention, as Figure 1-10 As shown, it includes a cotton feeding device 1 for conveying glass wool; a cotton feeding device 2 for conveying glass wool on the cotton feeding device 1 to be placed inside, and a cutting device for cutting the glass wool in the cotton feeding device 2 Cotton device 3; plate feeding device 4 for transporting battery plates; plate releasing device for placing battery plates, suction plate for sucking out battery plates on plate feeding device 4 and placing them on the plate releasing device Device 6; a plate pushing device 7 for pushing out the battery pole plate on the plate placing device; a plate ejecting device 8 for receiving and transporting the battery pole plate pushed out by the plate pushing device 7; and a frame.

[0028] The frame includes a frame body 91 and a casing 92 wrapped outside the frame body 91, the cotton feeding device 1 is arranged on the casing 91, the cott...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap