Permanent magnet yawing and variable pitch cycloid reduction box for wind power generation

A cycloid deceleration and yaw technology, which is applied in the field of variable pitch gearbox and wind power yaw, can solve the problems of complex structure, high price, long axial dimension, etc., and achieve good machining process performance, uniform manufacturing process, shaft For the effect that the size is short

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

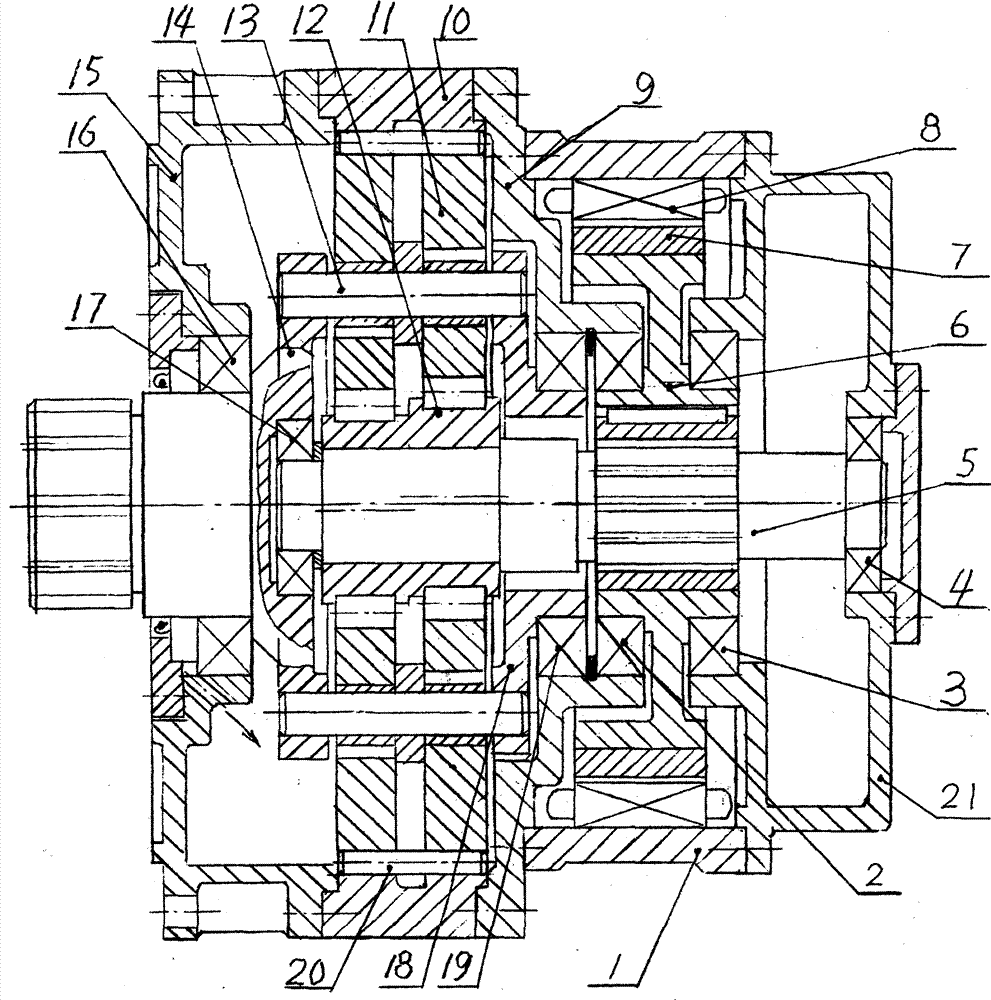

[0018] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS The present invention will be described in detail below in conjunction with the accompanying drawings:

[0019] refer to figure 1 . A permanent magnet yaw-pitch cycloidal reduction box for wind power generation, comprising a permanent magnet motor casing 1, a stator 8, a permanent magnet 7, a hollow rotor 6, and a single-stage cycloidal reduction component, and the front end of the motor casing 1 is sequentially Connect the embedded front end cover 9, the pin gear housing 10 and the machine base 15, and the rear end of the motor housing 1 is connected to the end cover 21, which is characterized in that:

[0020] (A) One side of the hollow rotor 6 is supported by the first bearing 2 in the inner hole of the embedded front end cover 9, and the other side is supported by the second bearing 3 in the inner hole of the end cover 21, and the inner hole of the hollow rotor 6 of the motor is It is slidingly matched with the exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com