Vehicle drive device

A driving device and vehicle technology, applied in the direction of power device, pneumatic power device, control drive, etc., can solve the problem of response delay and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 approach

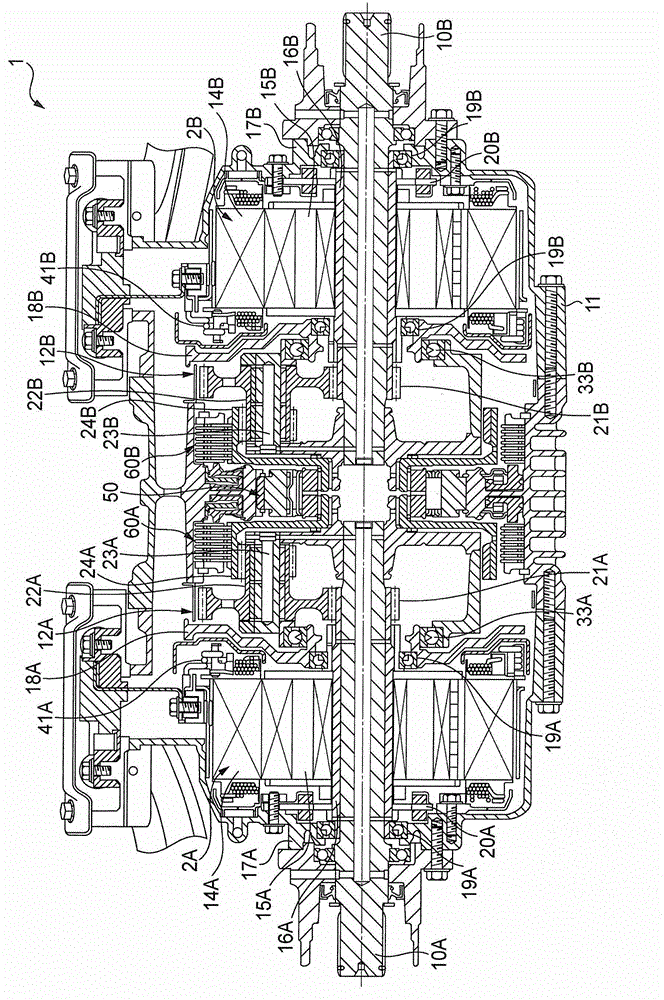

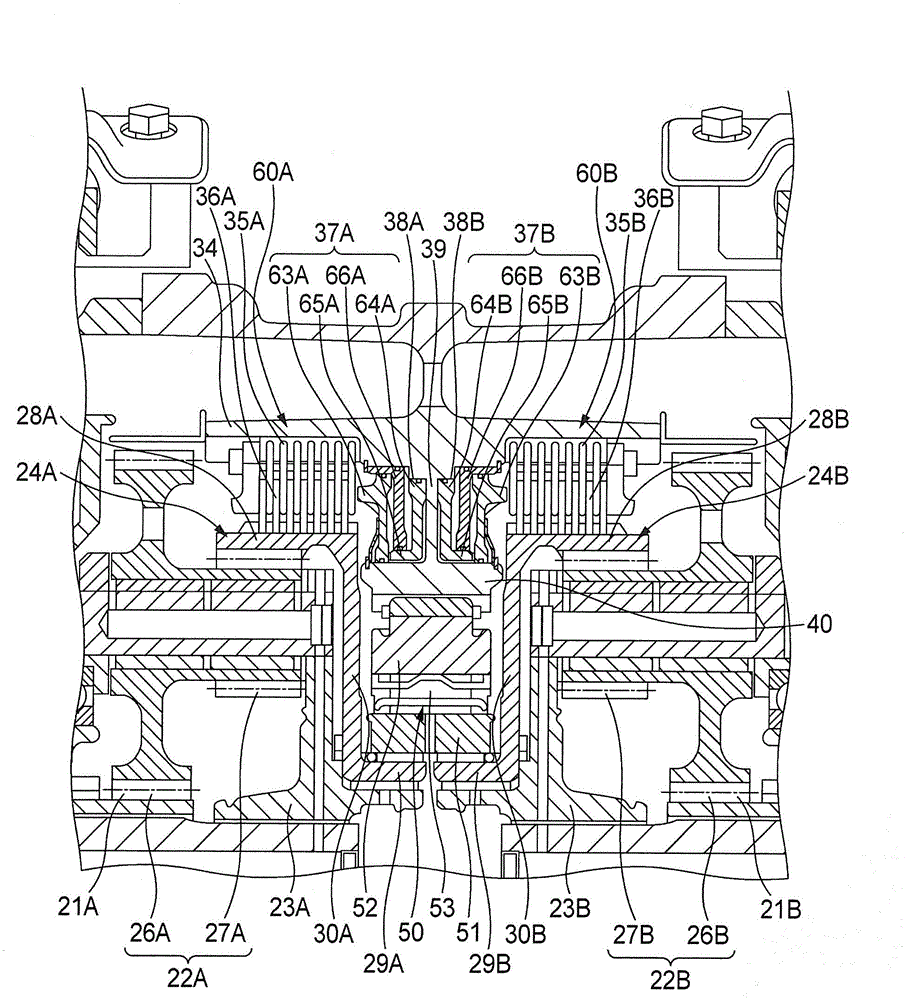

[0211] Next, refer to Figure 22 and Figure 23 , to describe the second embodiment of the present invention. It should be noted that, the drive device of the second embodiment has the same structure as the rear wheel drive device 1 of the first embodiment except for the arrangement of the hydraulic brake and the one-way clutch, so the same or equivalent parts are labeled the same or equivalent. symbols and their descriptions are omitted.

[0212] In the rear wheel drive device 1 of the present embodiment, a cylindrical space portion can be ensured between the speed reducer case 11 and the internal gear 24A, and in this space portion, the hydraulic brake 60 and the first pinion gear 26A are arranged in a radial direction. It is arranged so as to overlap upward and axially overlap with the second pinion 27A. In the hydraulic brake 60, a plurality of fixed plates 35 spline-fitted to the inner peripheral surface of the speed reducer housing 11 and a plurality of rotating plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com