Curable resin composition, surface protection method, temporary fixation method, and separation method

A curable resin, temporary fixing technology, applied in the direction of bonding method, non-polymer organic compound adhesive, special surface, etc., can solve the problems of inability to remove protective film, complicated cleaning process, and problematic working environment, etc. Achieve the effect of excellent workability, easy recycling, and shortened work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

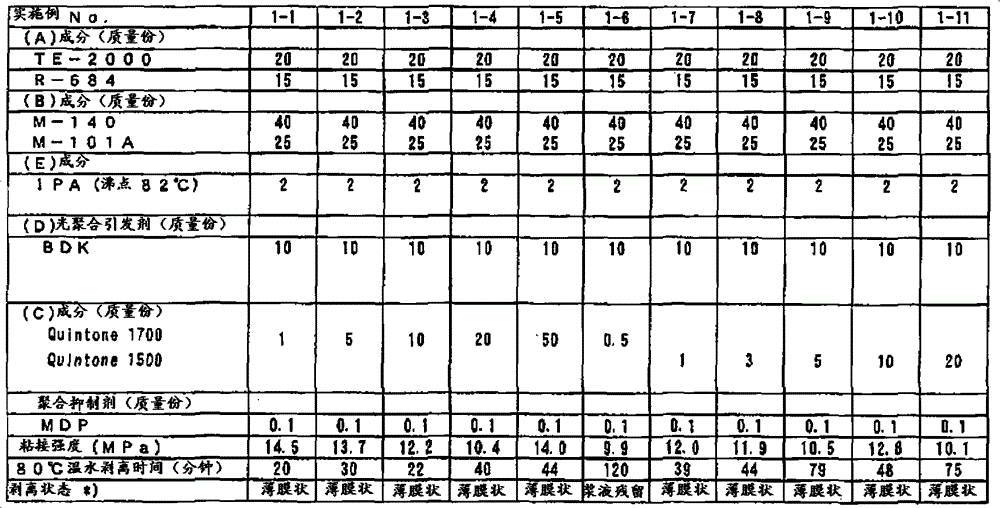

[0174] As (A) multifunctional (meth)acrylate, mix 20 parts by mass of TE-2000, 15 parts by mass of R-684, as (B) monofunctional (meth)acrylate, mix 40 parts by mass of M- 140, 25 parts by mass of M-101A, a total of 100 parts by mass of (A) and (B) and 1 part by mass of Quintone 1700 as (C) a resin having a cyclopentadiene skeleton, 10 parts by mass as (D ) BDK as a photopolymerization initiator, 2 parts by mass of IPA as a (E) polar organic solvent, and 0.1 part by mass of MDP as a polymerization inhibitor were blended to prepare a curable resin composition. Using the obtained curable resin composition, the measurement of the tensile shear adhesive strength of the hardened|cured body, and a peeling test were performed by the evaluation method shown above. These results are shown in Table 1-1.

Embodiment 1-2~1-21

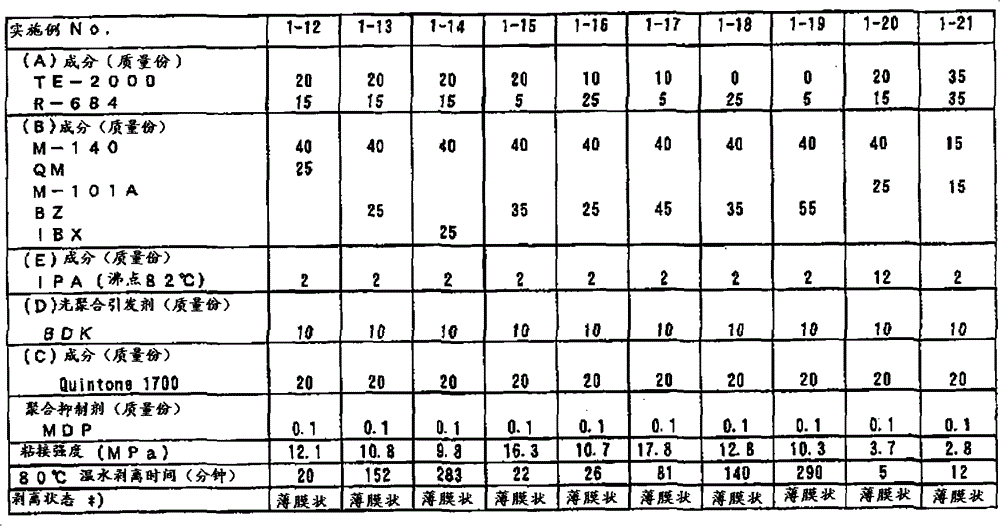

[0176] Except having used the raw material of the kind shown in Table 1-1 and Table 1-2 in the composition shown in Table 1-1 and Table 1-2, it prepared similarly to Example 1-1 and curable resin composition. About the obtained curable resin composition, the measurement of the tensile shear adhesive strength and the peeling test were performed similarly to Example 1-1. These results are shown in Table 1-1 and Table 1-2.

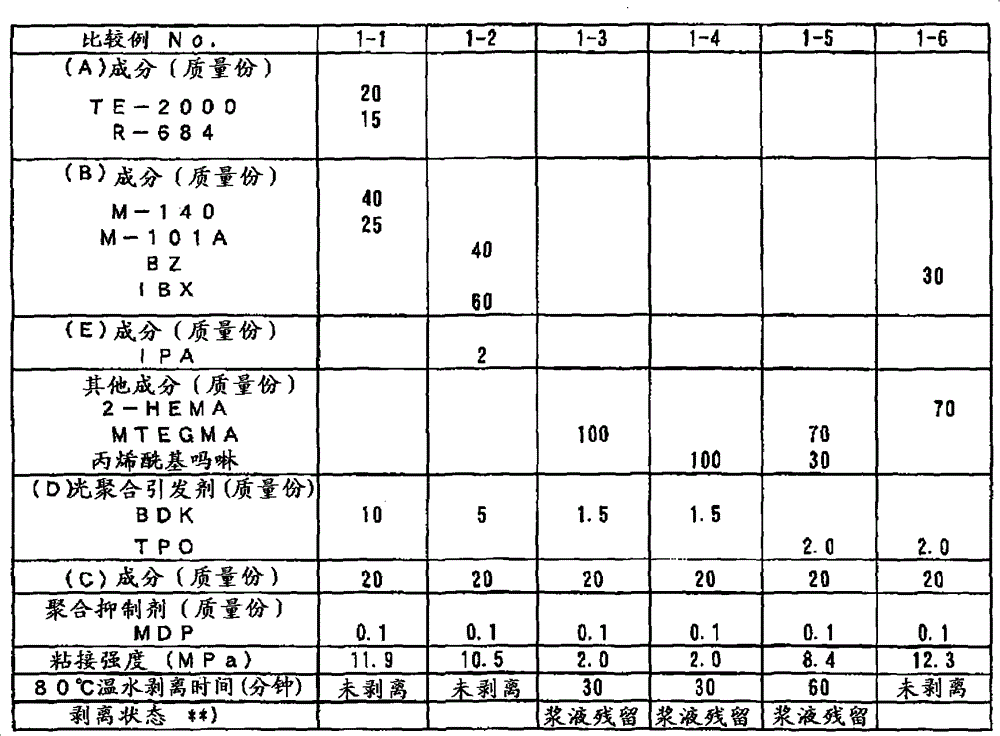

[0177] [Table 1-1]

[0178]

[0179] ) film form: The cured adhesive composition is peeled off the glass surface in a film form without slurry residue.

[0180] ) Slurry residue: Uncured adhesive remains on the surface of the cured product.

[0181] [Table 1-2]

[0182]

[0183] Slurry residue: Uncured adhesive remains on the surface of the cured product.

[0184] Film form: The cured adhesive composition is peeled off the glass surface in a film form without slurry residue.

Embodiment 1-22

[0191] Using the curable resin composition of Example 1-1, using a curing device made by Fusion Co., Ltd. using an electrodeless discharge lamp, the integrated light intensity at a wavelength of 365 nm was changed to 500, 1000, 2000, and 4000 mJ / cm 2 And the curable resin composition was hardened, and the measurement of the tensile shear adhesive strength and the peeling test were performed similarly to Example 1-1 except having produced the peeling test body and the tensile shear adhesive strength test piece. These results are shown in Tables 1-4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com