Plug-in coupling seal for a fluid line of a drive motor

A technology of sealing device and driving motor, applied in the direction of engine sealing, coupling, sleeve/socket connection, etc., to achieve the effect of improving sealing effect and good sliding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

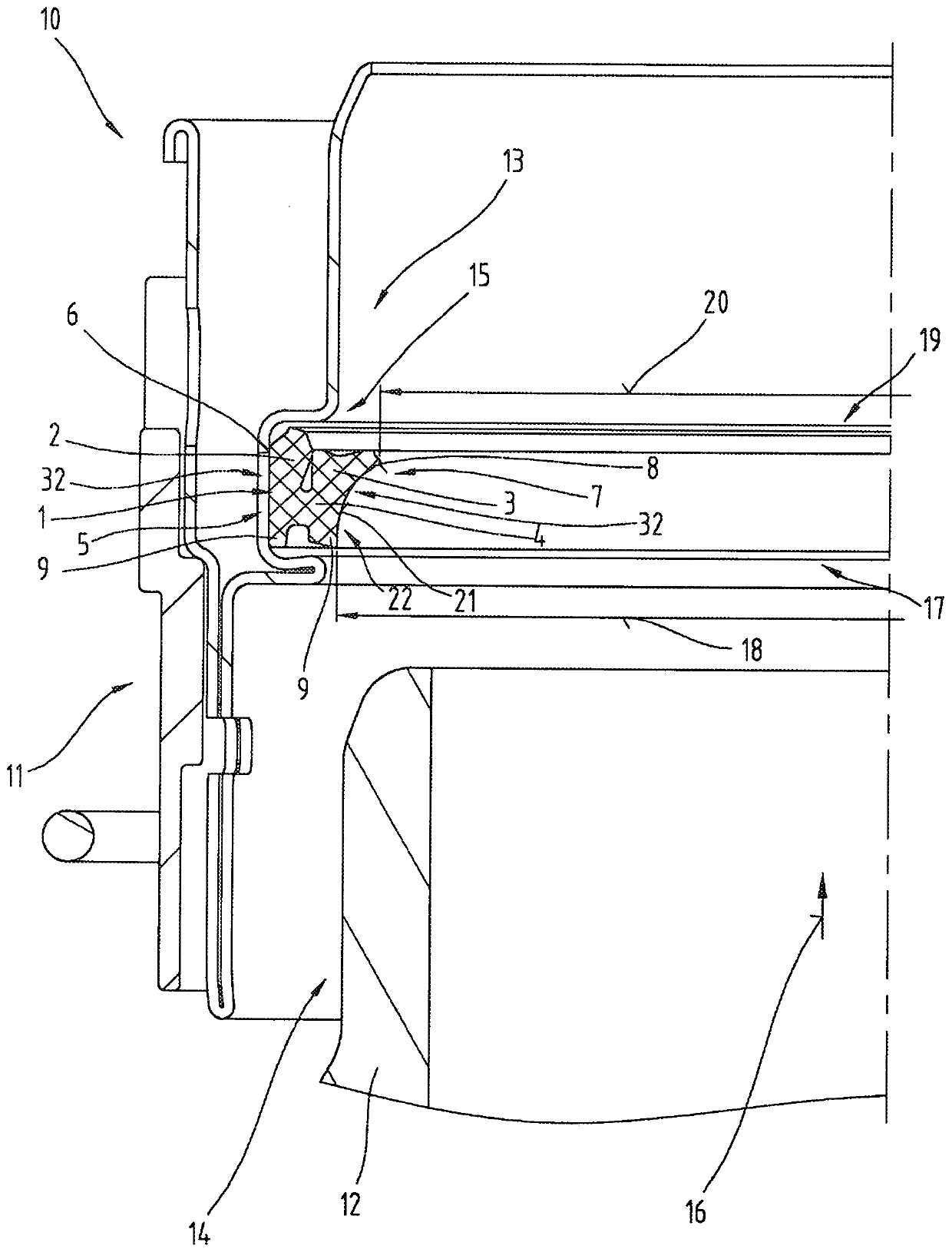

[0031] At the outset, it should be pointed out that in the different described embodiments, the same parts are provided with the same reference symbols or the same component designations, wherein the disclosure content contained in the entire description can be transferred to the reference symbols with the same reference symbols. Or on the same part with the same component name. The positional specifications selected in the description, such as top, bottom, sideways, etc., also refer to the directly described and illustrated figures, and these positional specifications are transferred to the new position in the event of a position change.

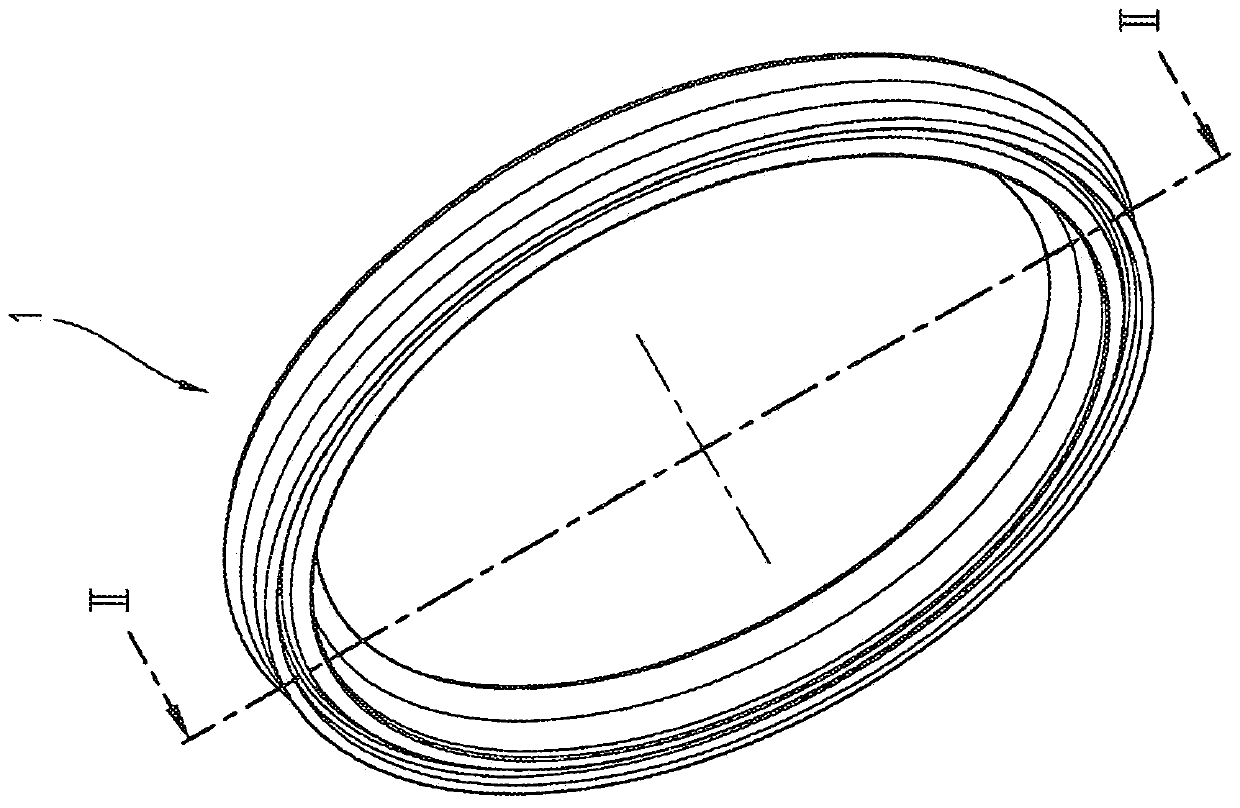

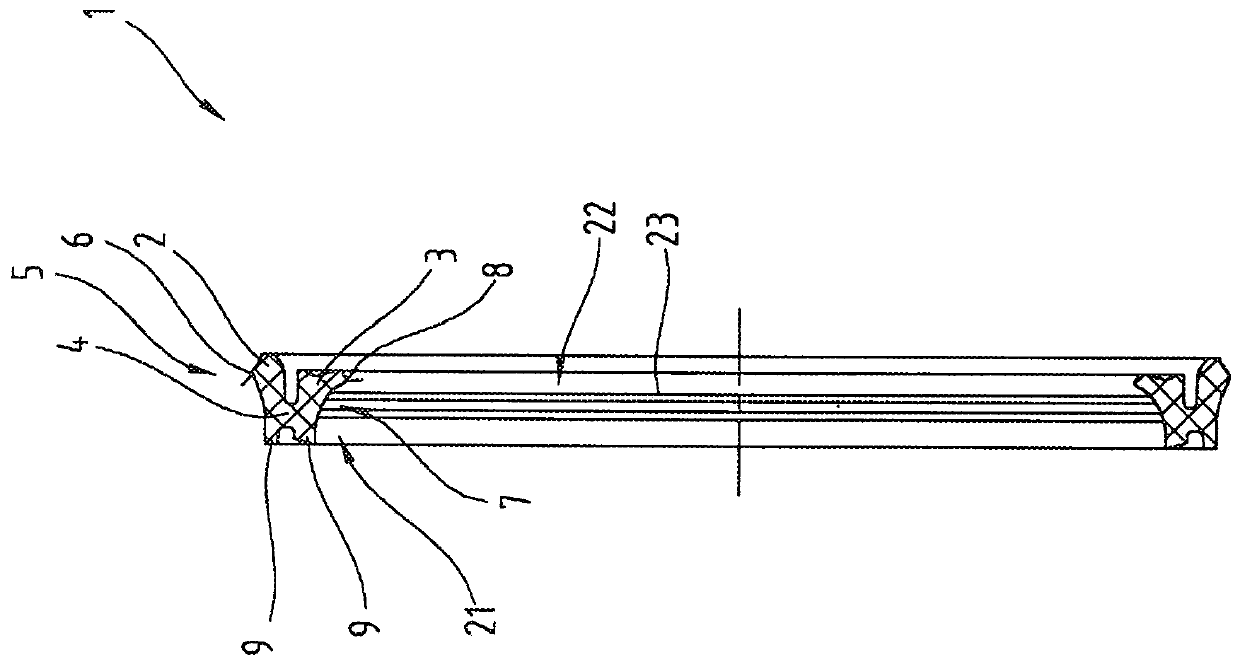

[0032] figure 1 A plan view of a first exemplary embodiment of an unassembled plug-in coupling seal 1 , which is designed as a sealing ring, is shown. Before discussing the exemplary embodiments according to the invention in detail, it should be pointed out that the plug-in coupling seal 1 according to the invention can not only be configu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com