Superconducting Strip Strip Joint Welding Device

A superconducting strip, indirect technology, applied in the direction of welding equipment, auxiliary equipment, auxiliary welding equipment, etc., can solve the problems of high joint resistance, poor mechanical properties, and difficulty in ensuring the welding uniformity of the overlapping section of superconducting strips, etc. Achieve the effects of small joint resistance, good mechanical properties, and ensure dimensional consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

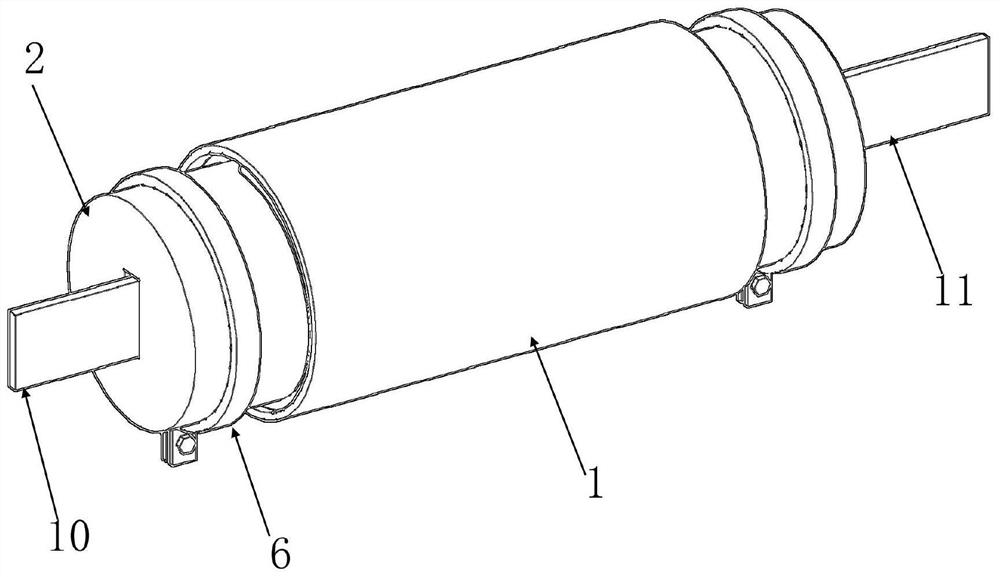

[0032] Such as figure 1 As shown, the embodiment of the present invention provides a superconducting strip inter-strip welding connection device, including an induction heating component 1 , a strip clamp 2 and an induction heating controller. The two superconducting strips to be welded are clamped by the strip clamp 2, a welding material, such as solder, is provided between the overlapping sections of the two strips, and the induction heating part 1 is controlled by the induction heating controller to heat the strip fixture. Therefore, the welding material is melted, and under the stress of the strip clamp 2, the molten welding material is evenly distributed between the superconducting strips to be welded.

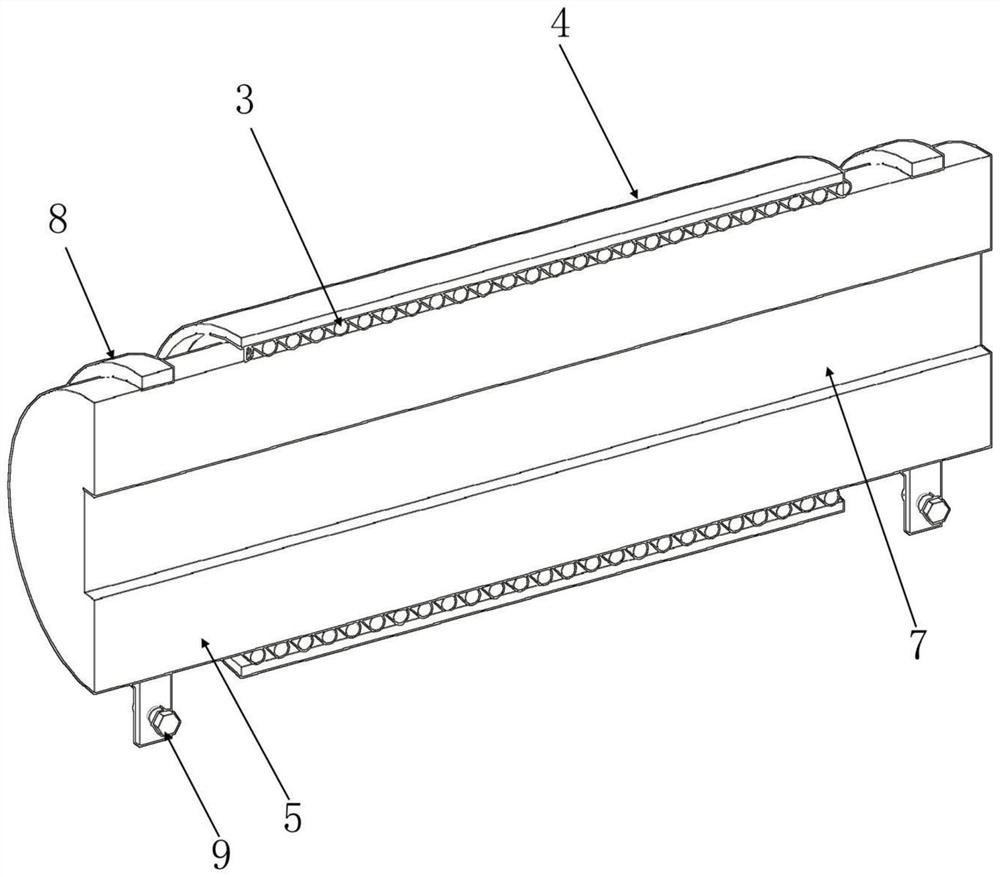

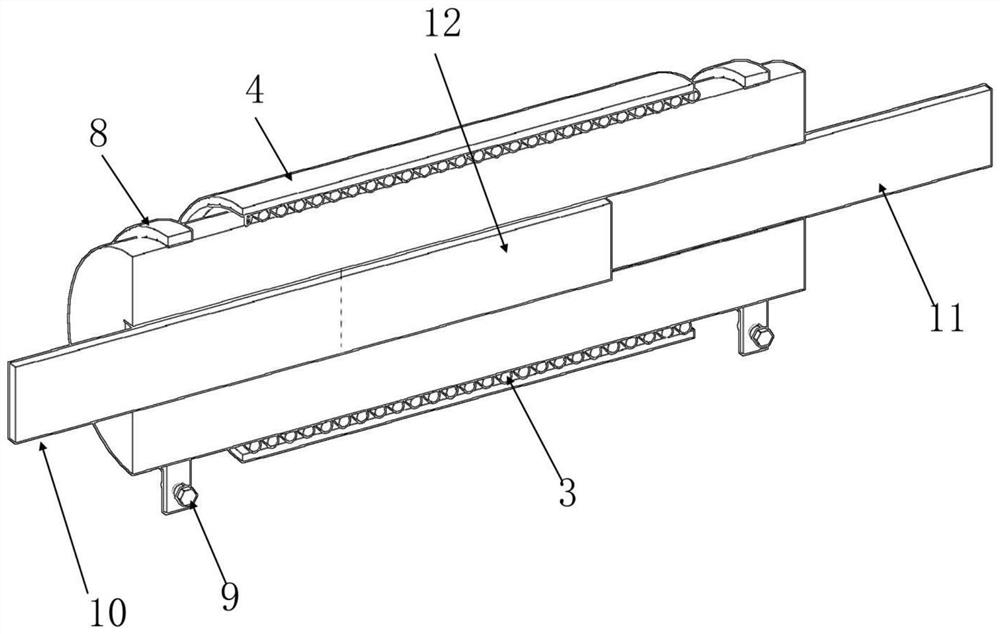

[0033] Such as figure 2 As shown, the induction heating component 1 includes a heating coil 3 and a heat insulation layer 4 sleeved on the heating coil, the heating coil 3 is connected to the induction heating controller; the strip clamp 2 includes two A semi-cylindric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com