Novel automatic fire-fighting terminal water testing system

A terminal water test, automatic technology, applied in fire rescue and other directions, can solve the problem of low degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

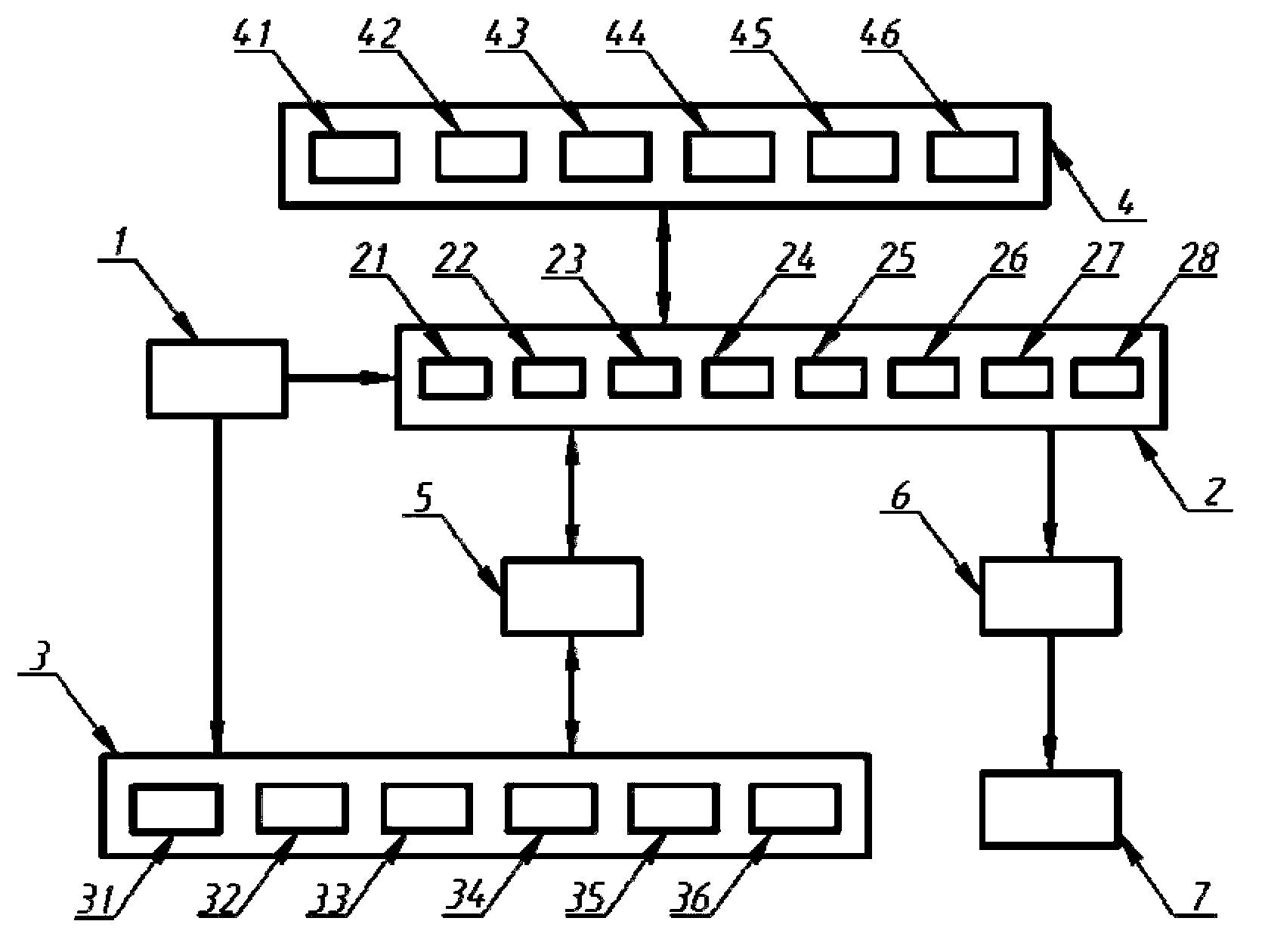

[0013] Such as figure 1 As shown, a fire automatic terminal water testing system includes a power supply 1, a fire automatic terminal water testing device 2, a central measurement and control device 3, a handheld terminal 4, a communication bus 5, a water testing joint 6 and a drain funnel 7.

[0014] Wherein the fire automatic terminal water testing device 2 includes a communication module 21 , a display module 22 , a flow sensor 23 , a measurement control module 24 , an electric control valve 25 , an alarm 26 , a status indicator light 27 , and a function button module 28 .

[0015] The flow sensor 23 in the fire-fighting automatic terminal water testing device 2 adopts an ultrasonic flowmeter. The advantage of the ultrasonic flowmeter is that it has a compact structure and is easy to install, and the ultrasonic flowmeter has no mechanical movement, no wear, and is not easily affected by bad water quality. And low maintenance costs. The flow sensor 23 can obtain the flow si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com