Machine tool for processing inlet/outlet water passages of water meter shell

A water inlet and outlet, shell technology, applied in metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of inability to process water meter inlet and outlet channels at the same time, poor stability of water meter flow curve, low production efficiency, etc., to avoid The effect of unqualified processing, low cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

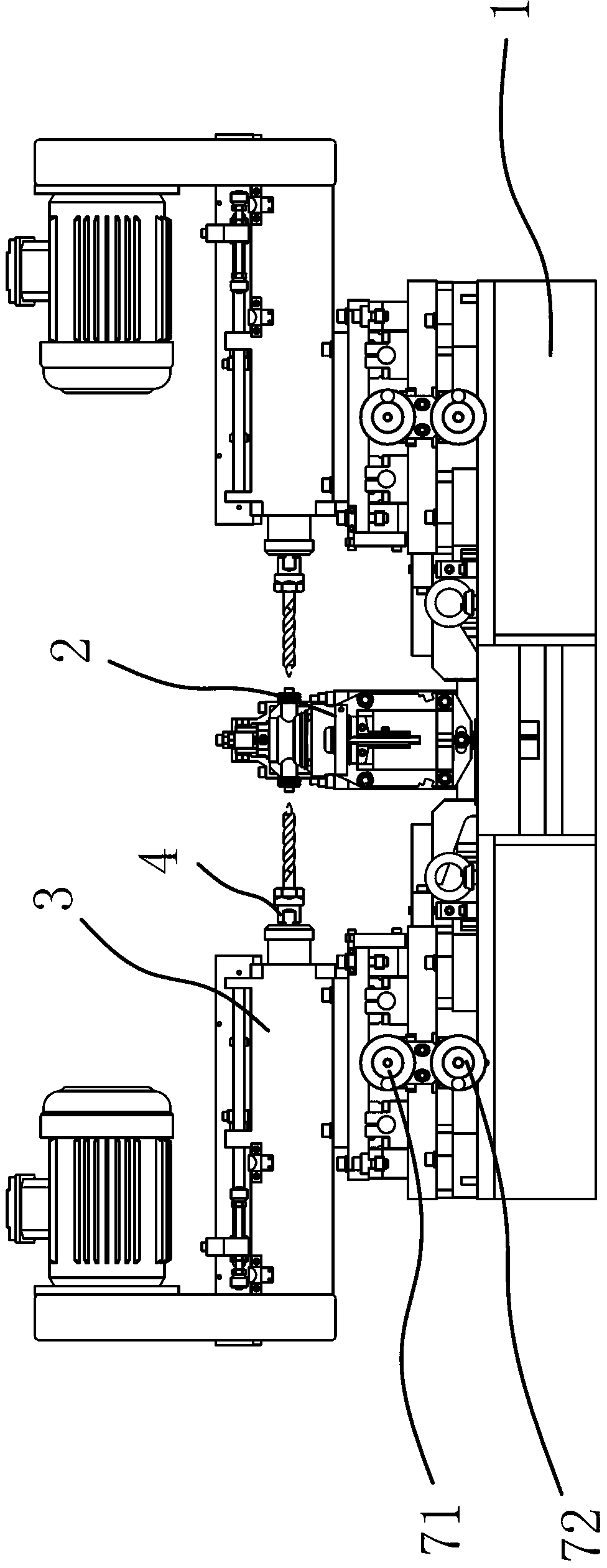

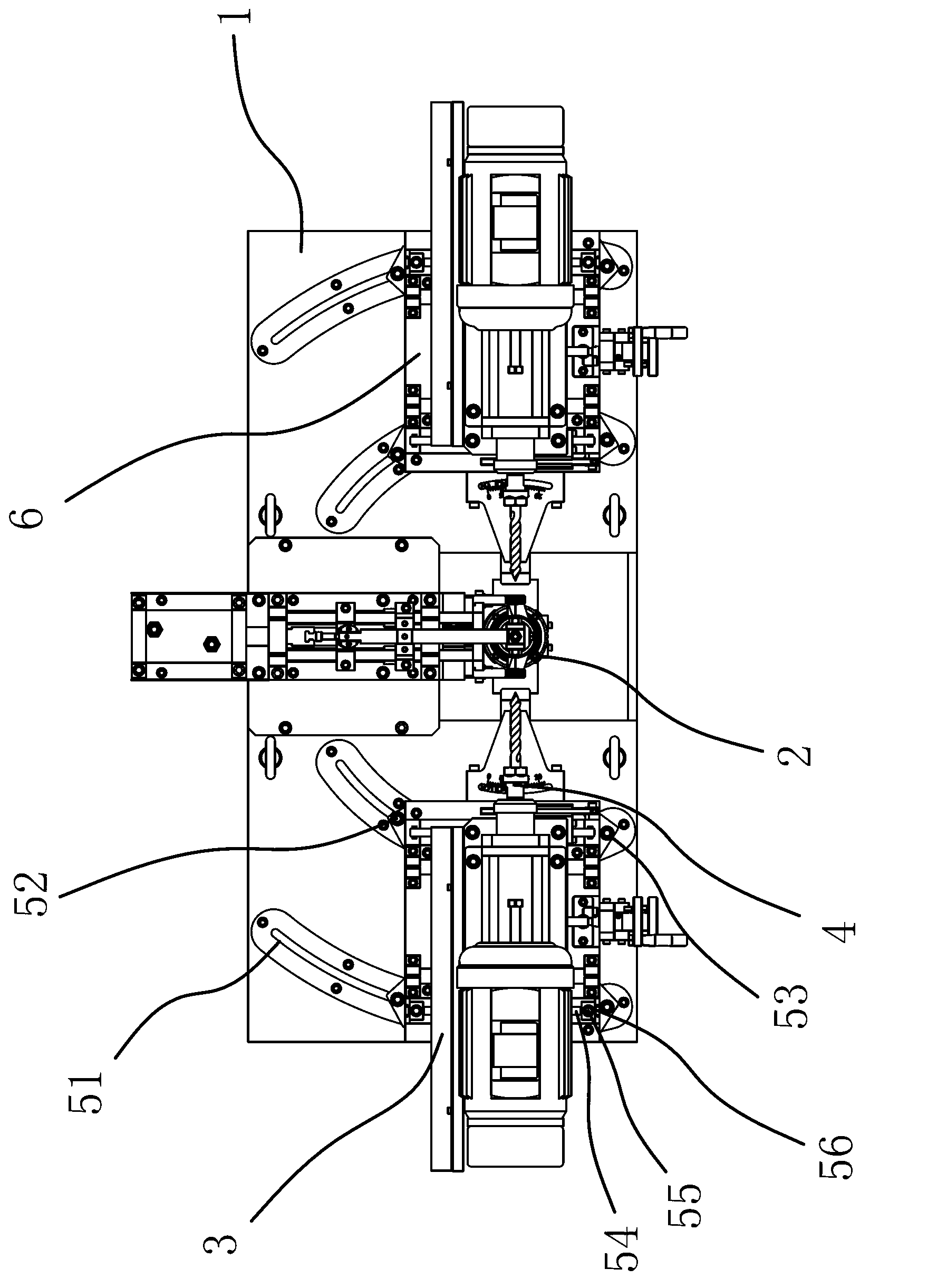

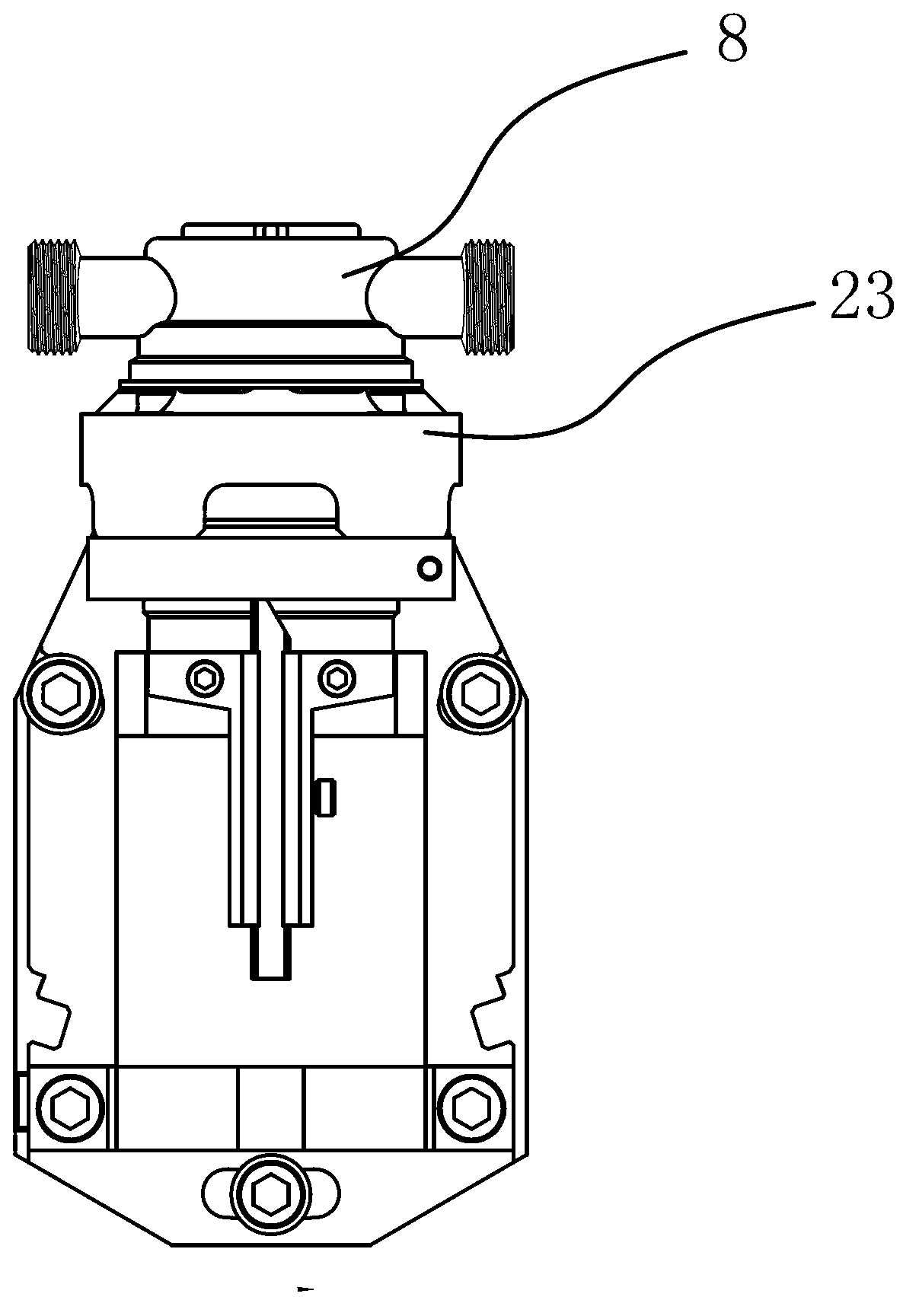

[0030] like Figure 1-5 As shown, the machine tool used to process the water inlet and outlet channels of the water meter housing includes a machine base 1 and a clamp 2 arranged in the middle of the machine base 1 . Both sides of the fixture 2 are provided with a power head assembly having a power head seat 3 and a rotating shaft 4, the rotating shafts 4 are all facing the clamp 2, and there is at least an adjustable rotating shaft 4 between each power head seat 3 and the base 1. Adjustment device for swinging on the horizontal plane.

[0031] More specifically, the adjustment device includes two sets of arc-shaped slide rail assemblies arranged in parallel and located between the power head base 3 and the machine base 1 to enable the axis of the rotating shaft 4 to swing along the horizontal plane. The arc-shaped slide rail assembly includes an arc-shaped guide rail 51 with a guide groove and a sliding head 1 52 capable of sliding along the guide groove, and the arc-shaped ...

Embodiment 2

[0037] like Figure 3-6 As shown, the basic structure and principle of the machine tool for processing the inlet and outlet channels of the water meter casing in this embodiment are basically the same as those in Embodiment 1, the difference is that the adjustment device includes a Two groups of arc-shaped slide rail assemblies arranged in parallel can make the axis of the rotating shaft 4 swing along the horizontal plane. The arc-shaped slide rail assembly includes an arc-shaped guide rail 51 with a guide groove and a sliding head 1 52 capable of sliding along the guide groove. The arc-shaped guide rail 51 is fixed on the support 1, and the sliding head 1 52 is fixedly connected with the power head seat 3, and a fastener 1 53 that enables the two to be fixedly connected is provided between the power head seat 3 and the arc-shaped guide rail 51. A screw nut assembly 1 is arranged between the two groups of arc-shaped slide rail assemblies. One end of the screw rod in the scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com