Wood carbonizing device

A carbonization device and wood technology, applied in the direction of charcoal burning/burning, etc., can solve the problems affecting the appearance quality of wood, so as to avoid the growth of mold and ensure the effect of appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below with reference to the drawings and embodiments.

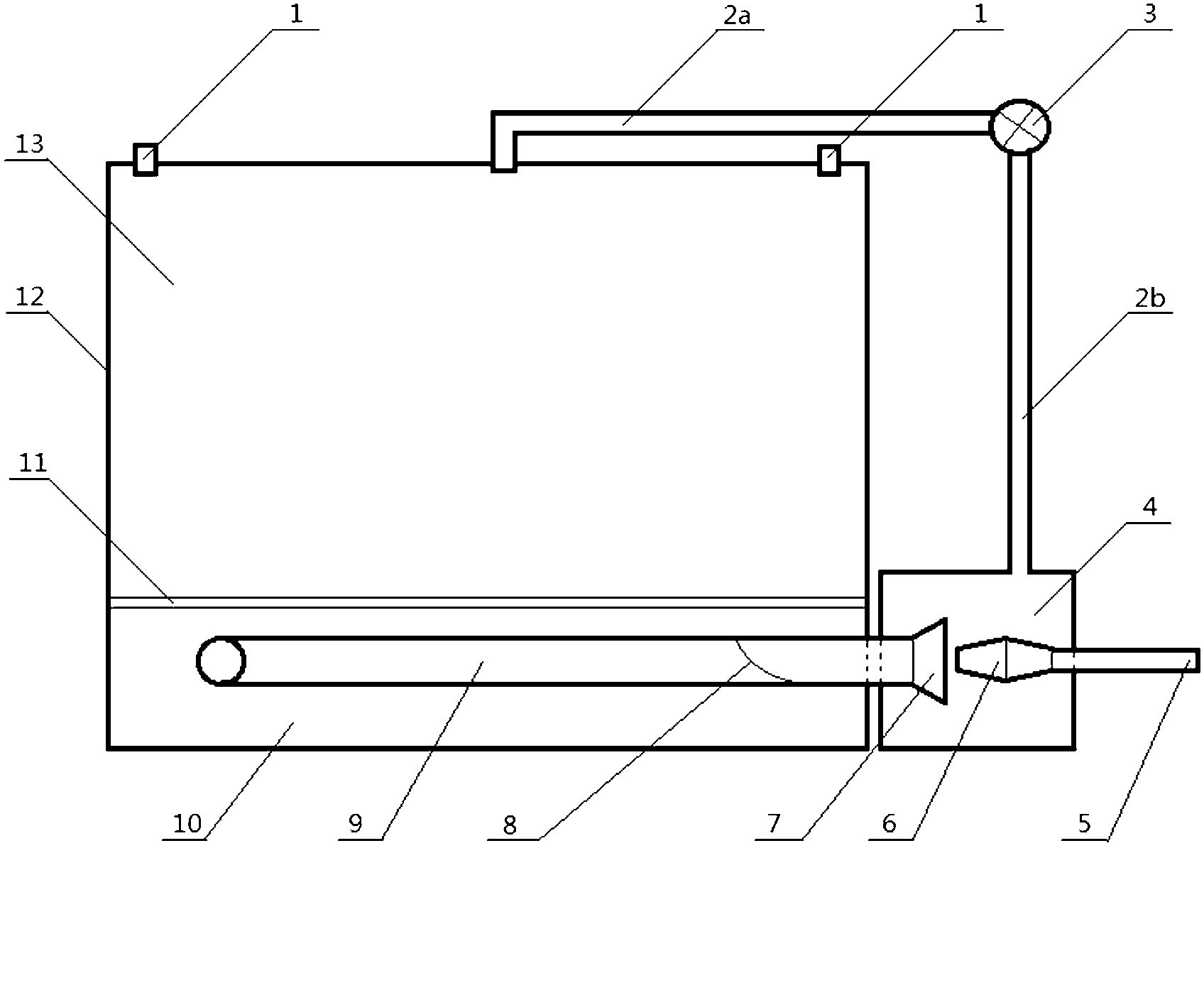

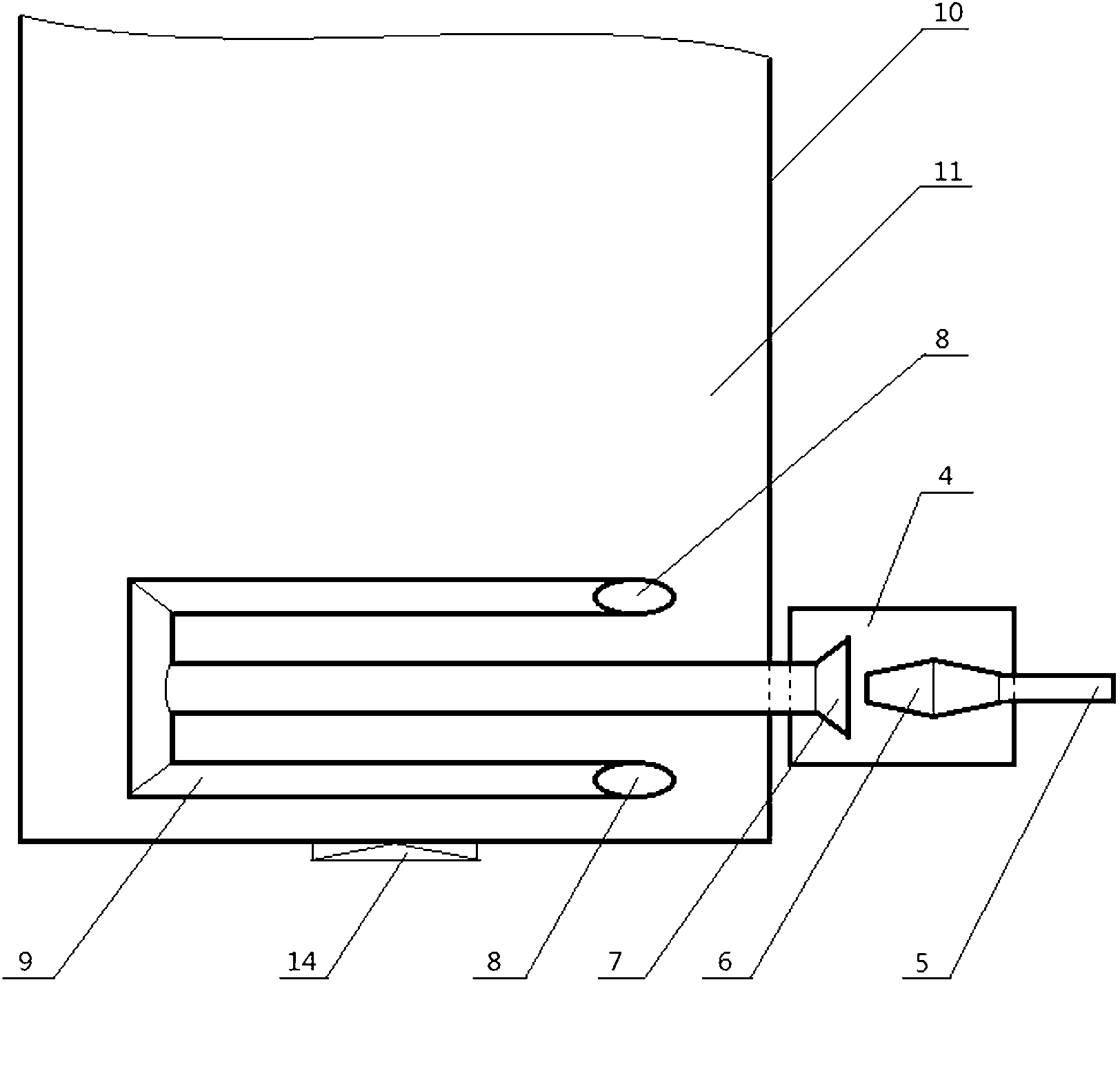

[0018] A wood carbonization device includes a carbonization box 12, a door 14, a ventilated wood holding partition 11, a unidirectional moisture exhaust hole 1 and a heating component. The partition 11 is arranged at the lower part of the carbonization box 12, and divides the carbonization box into the upper and lower parts of the wood holding area 13 and the heating area 10. The wood holding area is used to place the wood to be carbonized. Two unidirectional moisture exhaust holes 1 are provided on the top wall of the carbonization box for exhausting wood vapor.

[0019] The heating components of the wood carbonization device include a mountain-shaped hot gas discharge pipe 9, a gas burner 6, a gas pipe 5, a combustion chamber 4, a hot air blower 3, and a hot air circulation pipe 2a, 2b. The combustion chamber 4 is a closed container, the hot gas discharge pipe 9 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com