Shrink tunnel

A technology of shrinking channel and plane, applied in the direction of wrapping paper shrinkage, furnace type, lighting and heating equipment, etc., to achieve the effect of quick replacement, simple cost and good adaptation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

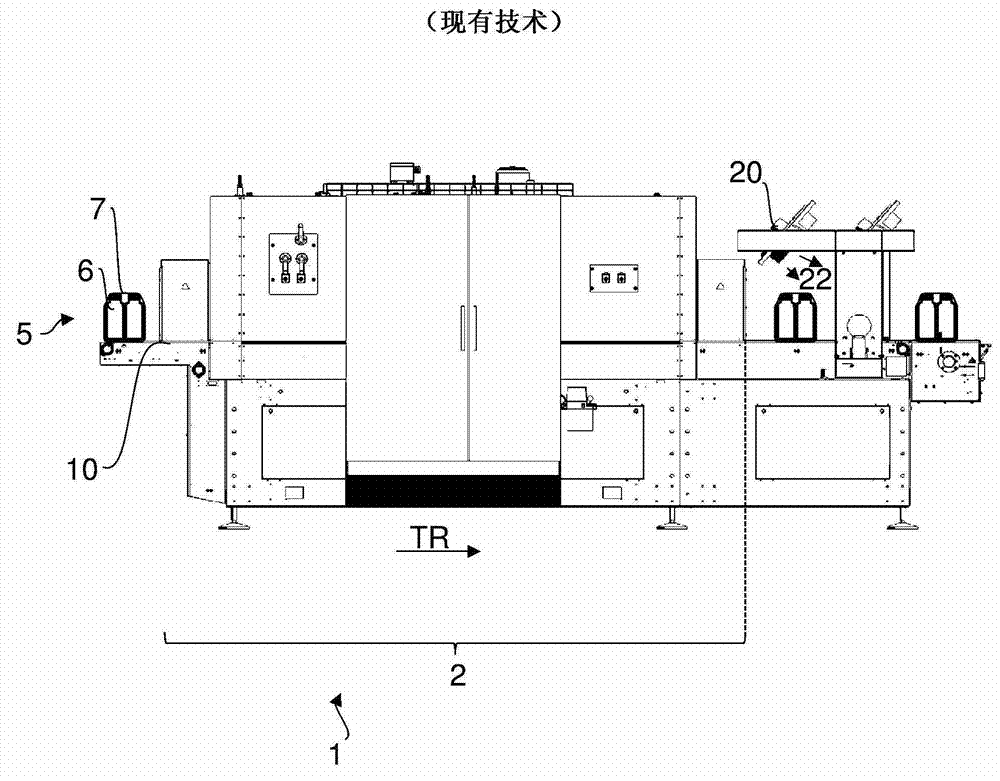

[0036] figure 1 A schematic view of a shrinking device 1 according to the known prior art is shown. Items, in particular beverage containers, bottles 6 , cans or the like are put together in groups and wrapped with a shrink film 7 . These arrangements are also referred to as clusters 5 . The bundles 5 are transported on the conveyor belt 10 to the shrink tunnel 2 in the transport direction TR. Arranged in the shrink tunnel 2 are heating means (not shown), which, for example, impinge the bundle 5 with hot air, thereby shrinking the film 7 surrounding the bottle 6 . After the bundles 5 leave the shrink tunnel 2 , they are cooled with cooling air 22 by a fan 20 arranged above the conveyor belt 10 .

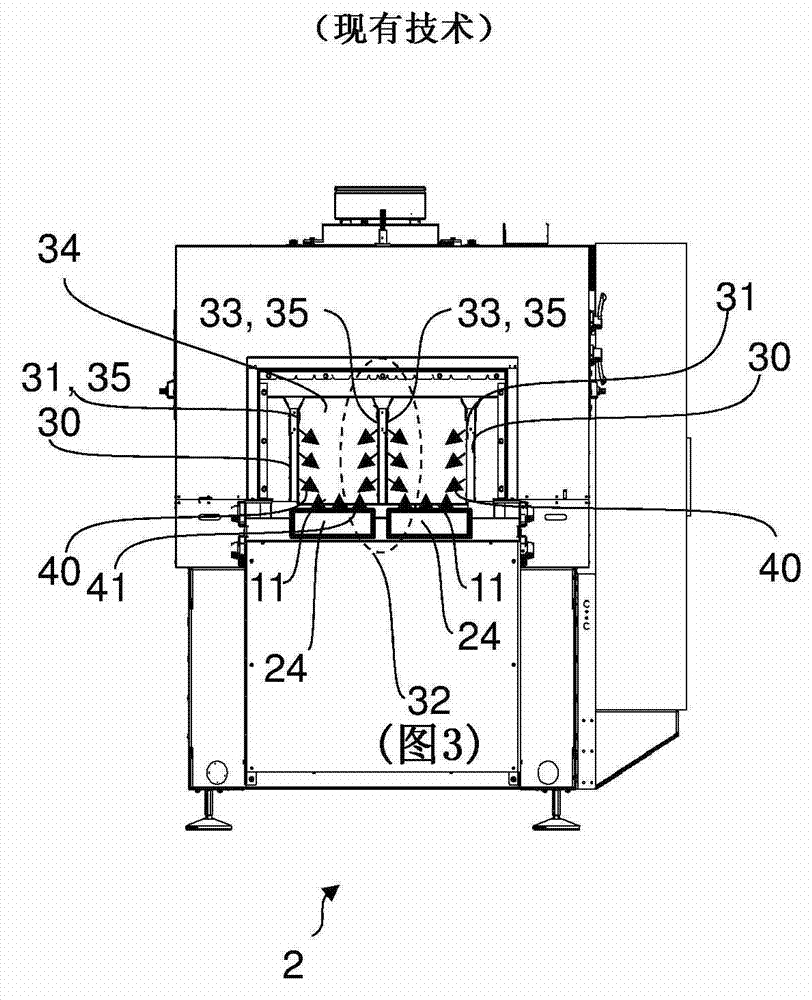

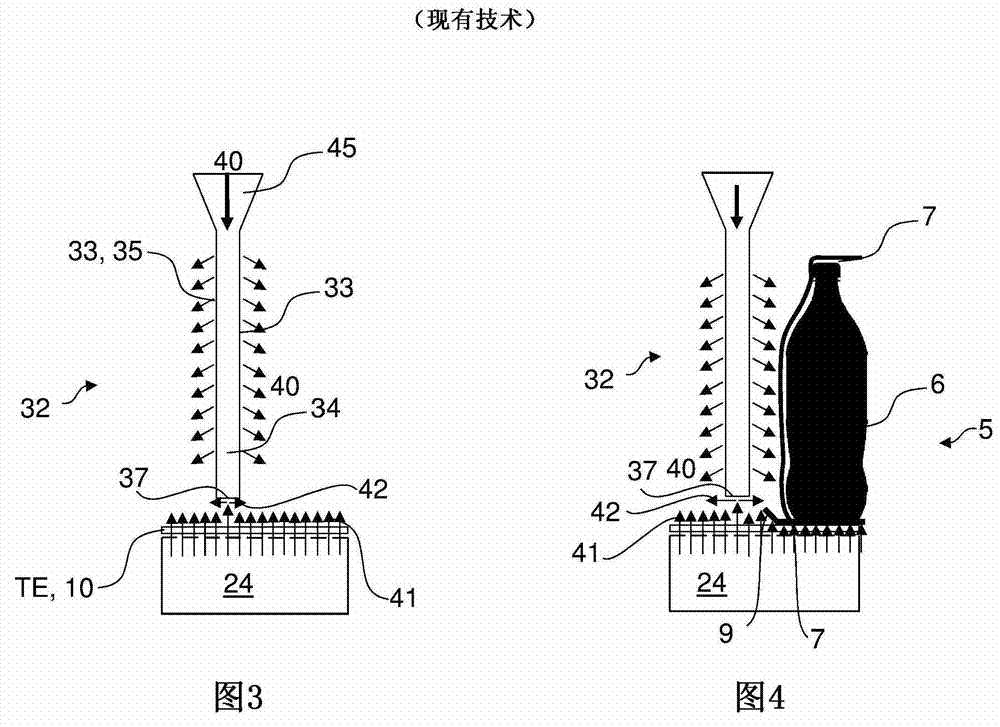

[0037] figure 2 A cross-section of the shrink tunnel 2 with two transport rails 11 for bundles (not shown) is shown. Via the so-called well walls 30 , 32 , hot air 40 is blown into the inner space 34 of the constriction channel 2 . The outer shaft wall 30 has nozzle openings 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com