Liquid crystal aligning agent

A liquid crystal alignment agent and polymer technology, applied in liquid crystal materials, chemical instruments and methods, etc., can solve the problems of difficult ionic charge detachment, image afterimage, etc., achieve low residual DC voltage, improve afterimage characteristics, high voltage Retention rate and effect of residual DC voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

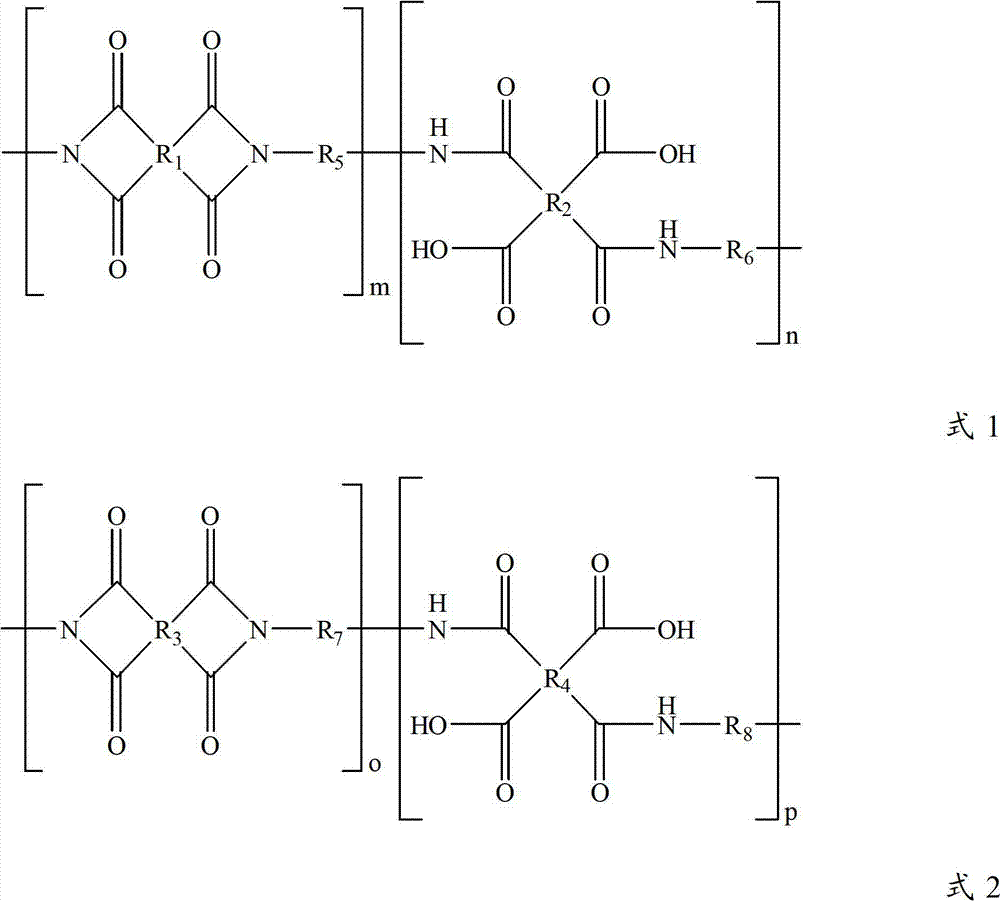

[0102] Synthesis methods of Synthesis Example Polymers A1-A7 will be described below.

[0103] Add the tetracarboxylic dianhydride compounds listed in Table 1 and the diamine compounds listed in Table 2 to N-methyl-2-pyrrolidone (the ratio is shown in Table 3) to prepare a solid content of 25% by weight solution, and react at 40°C for 5 to 6 hours to obtain polyamic acid. Next, add an appropriate proportion of acetic anhydride and pyridine to the obtained polyamic acid solution (the amount depends on the imidization ratio), and perform a dehydration / ring closure reaction at 100°C to 110°C for 3 to 4 hours.

[0104] The amount of acetic anhydride in the above appropriate proportion is preferably 0.01 to 20 moles of acetic anhydride per 1 mole of polyimide-polyamic acid reproducing units. It is preferable to use 0.01 to 10 moles of pyridine per 1 mole of acetic anhydride.

[0105] The resulting solution was precipitated with ethanol and purified with ethanol. Finally, they we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com