Stepped ultrasonic impact needle device and application thereof

An ultrasonic impact and step-type technology, which is applied in the field of impact pins where ultrasonic impact eliminates stress on the surface of certain materials or in the heat-affected zone of welding. problems, to achieve high-efficiency residual tensile stress, increase impact velocity, and reduce energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

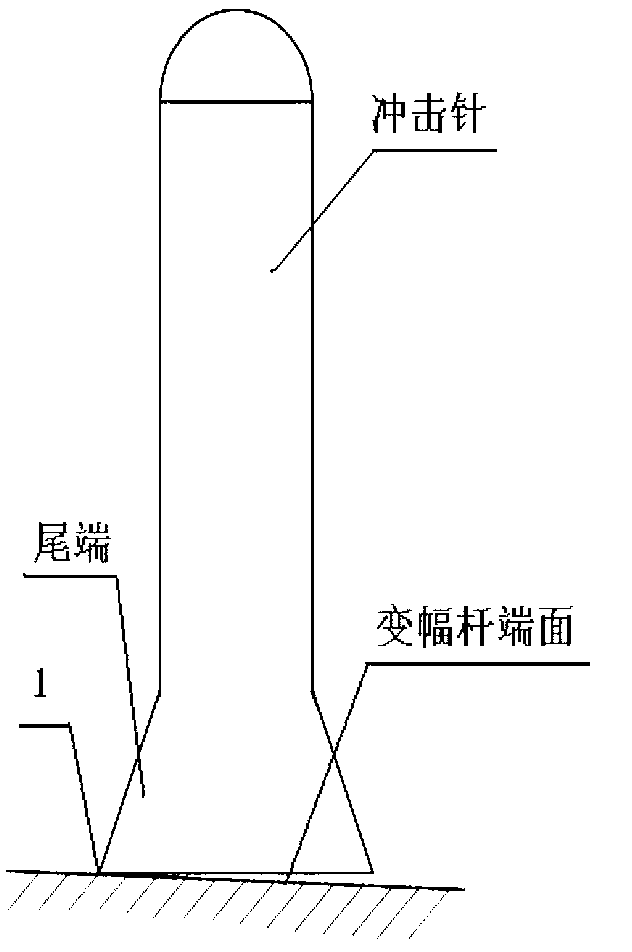

[0031] Example 1 The step-shaped impact needle is matched with the extension head of the pit-shaped impact needle

[0032] as attached Figure 5As shown, the structure is composed of impact needle seat 1, impact needle 2 and impact needle extension head 3 with a pit. The shape of the impact needle seat is a cylindrical structure, and the muzzle is cone-shaped. And on the outer circumference, there is a protrusion for loading and unloading, the opening end is matched with the shell of the ultrasonic impact gun (not shown in the figure), and then fixed with a flange, and the loading and unloading protrusion 5 plays a fixed role between the flange and the shell of the impact gun; The other end is sealed, which is the muzzle end, and is provided with baffles 7 and 8, on which there is a round hole matched with the impact needle. The diameter of the stepped cylinder (D is 1.3d; l is 0.2L) reduces friction when the impact needle collides with the muzzle of the impact needle seat. B...

Embodiment 2

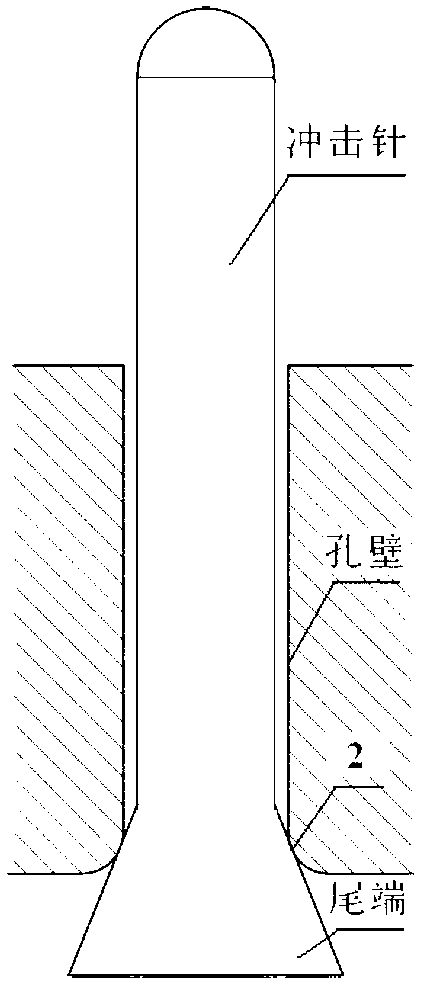

[0033] Example 2 The step-type impact needle is matched with the extension head of the flat-type impact needle

[0034] as attached Figure 6 As shown, the structure is composed of impact needle seat 1, impact needle 2 and impact needle extension head 3 with a pit. The shape of the impact needle seat is a cylindrical structure, and the muzzle is cone-shaped. And on the outer circumference, there is a protrusion for loading and unloading, the opening end is matched with the shell of the ultrasonic impact gun (not shown in the figure), and then fixed with a flange, and the loading and unloading protrusion 5 plays a fixed role between the flange and the shell of the impact gun; The other end is sealed, which is the muzzle end, and is provided with baffles 7 and 8, on which there is a round hole matched with the impact needle. The diameter of the needle is a stepped cylinder (D is 1.3d; l is 0.1L), which reduces the friction when the impact needle collides with the muzzle of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com