Servo control system and method for eliminating torsional vibration of rollers of ring spinning frame

A servo control system and technology of spinning frame, applied in spinning frame, continuous winding spinning frame, textile and paper making, etc., can solve the problems of economic loss, roller torsion deformation, etc., to extend service life, eliminate roller torsion The effect of vibration and preventing roller breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

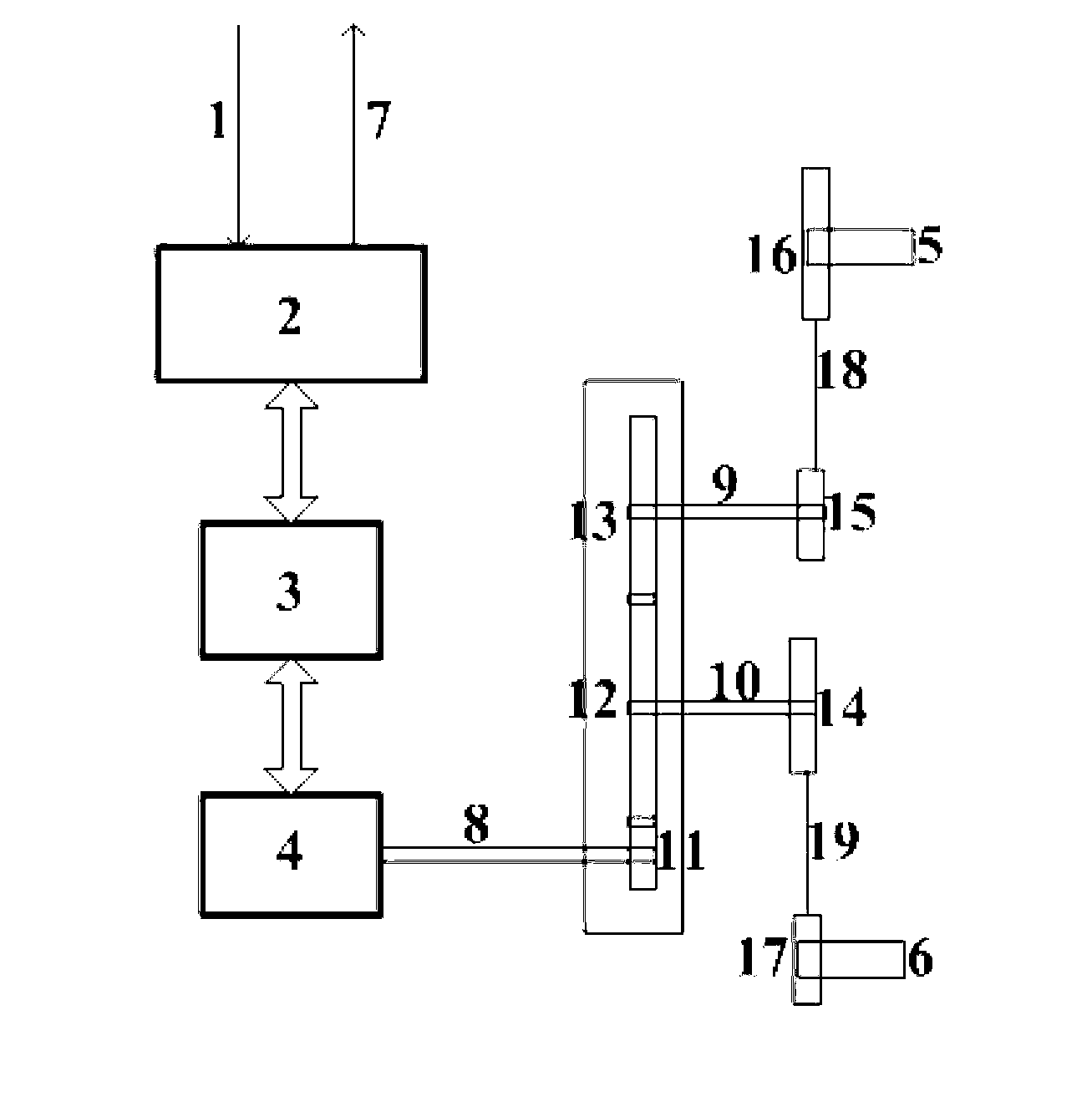

[0012] Below in conjunction with accompanying drawing, the present invention will be further described.

[0013] like figure 1 As shown, a servo control system that can eliminate roller torsional vibration includes a servo driver 3, a servo motor 4, and a programmable logic controller 2, wherein the servo motor 4 drives the gear 11 through the motor shaft 8, and the gear 11 and the gear 12 are meshed with each other. , the gear 12 is connected with the gear 14 through the connecting shaft 10, and the gear 14 drives the gear 17 on the left-hand front roller 6 through the synchronous belt 19, and finally realizes the torque compensation of the servo motor 4 to the left-hand front roller 6, the gear sets 11 and 12 and the gear set 14 and 17 jointly realize the deceleration control; the gear 12 and the gear 13 are meshed and connected with each other, the gear 13 is connected with the gear 15 through the connecting shaft 9, and the gear 15 drives the gear 16 on the right-hand fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com