A steel pallet support force transmission system

A force transmission system and pallet technology, applied in pillars, building maintenance, infrastructure engineering, etc., can solve problems such as uneven support force, affect construction, and take up space, achieve strong support stability, reduce construction costs, and take up space. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

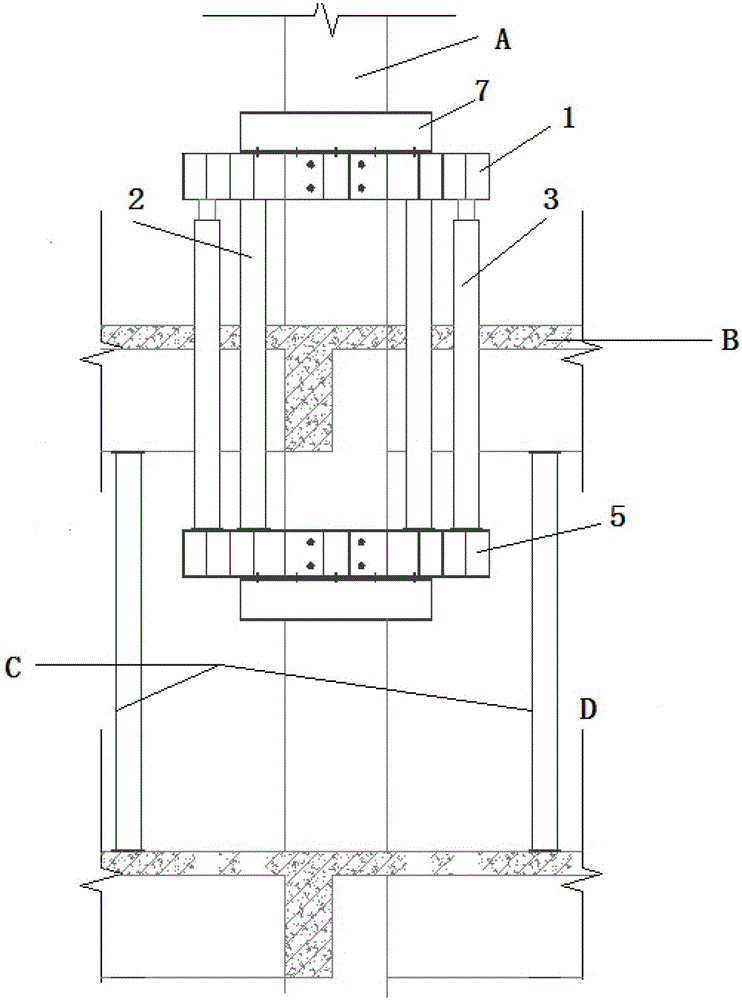

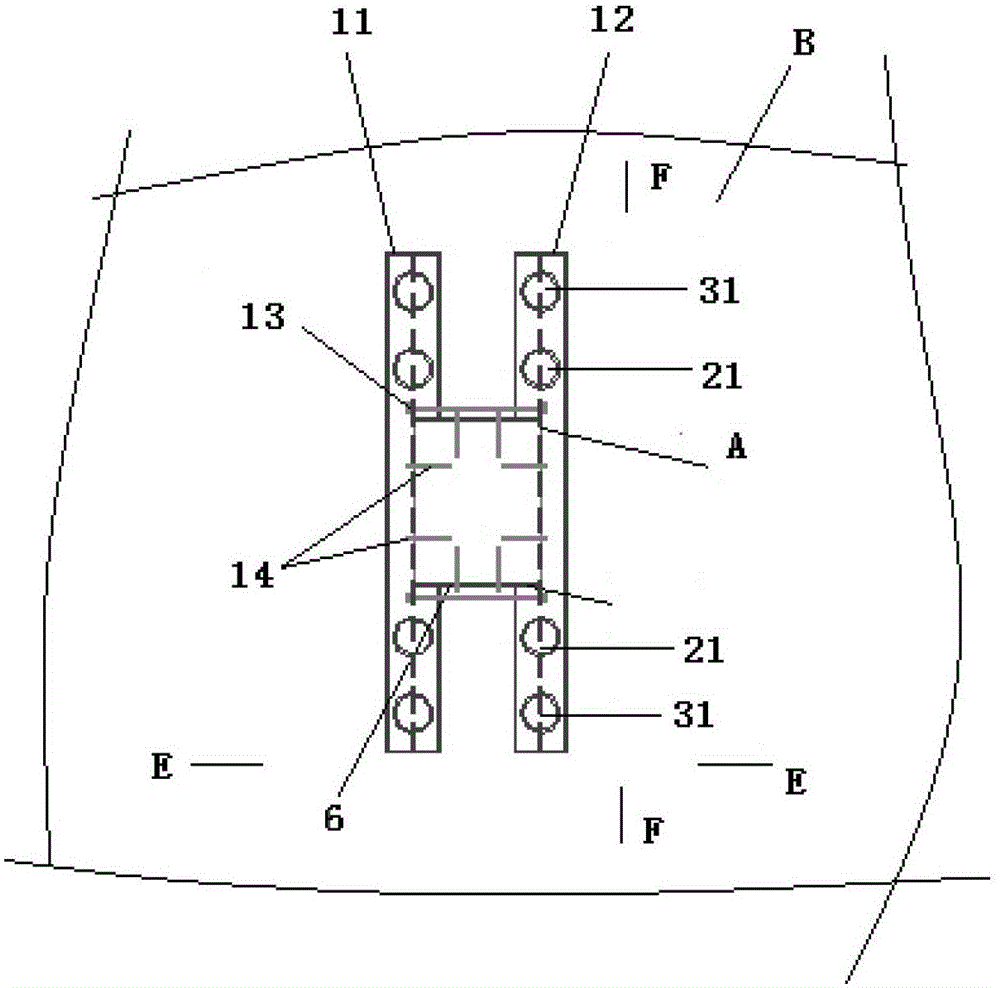

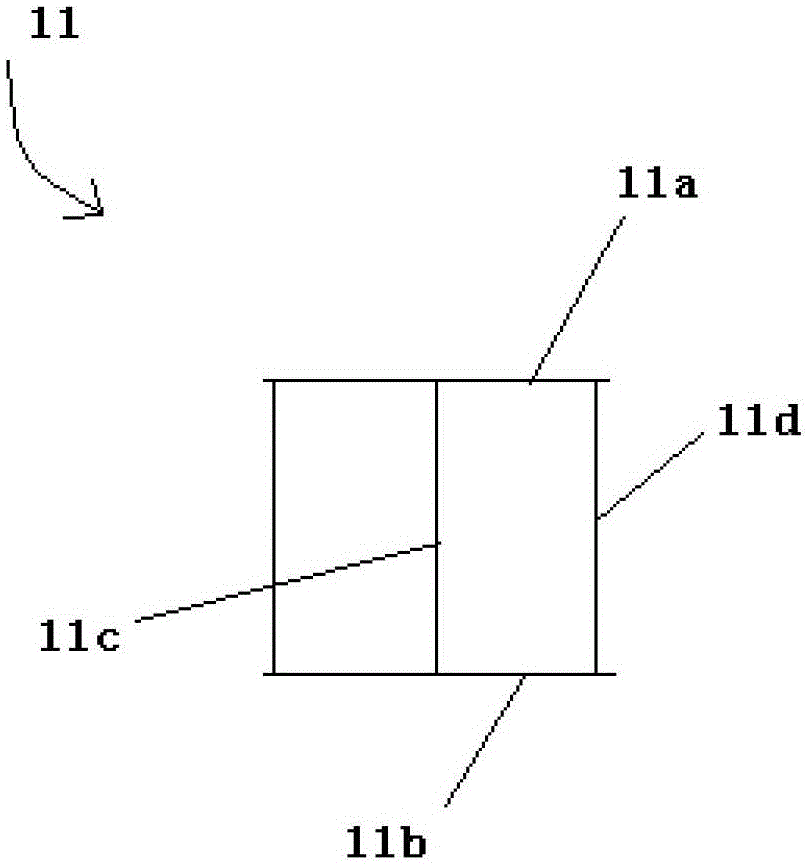

[0028] see Figure 1~Figure 5 , the steel tray support force transmission system of this embodiment includes an upper steel tray assembly 1, a main support assembly 2, an auxiliary support assembly 3, a jack 4, and a lower steel tray assembly 5; wherein, the upper steel tray assembly is located on the floor B, and the lower The steel tray assembly is located between the floors B and D, the main support assembly and the auxiliary support assembly pass through the floor B; a joint support system C is provided between the floor B and the floor D; the upper steel tray assembly 1 includes horizontally arranged along its length The first steel beam 11 and the second steel beam 12 on the opposite sides of the underpinned or replaced column A, the lower steel tray assembly 5 includes horizontally arranged on the opposite sides of the underpinned or replaced column along its length direction The third steel beam 51 and the fourth steel beam 52, wherein the structures of the first steel...

Embodiment 2

[0043] see Figure 6 ~ Figure 8 , the steel tray supporting force transmission system of this embodiment is used for shear wall underpinning, and it includes an upper steel tray assembly 1 and a lower steel tray assembly 5, and a main support assembly arranged between the upper steel tray assembly and the lower steel tray assembly 2 and auxiliary support assembly 3. Wherein, the upper steel tray assembly 1 is located on the floor H above the shear wall G to be underpinned, and the lower steel tray assembly 5 is located on the floor I below the shear wall G to be underpinned; the upper steel tray assembly 1 includes several intervals. The upper steel beam 1a, the lower steel tray assembly 5 includes a plurality of lower steel beams 5a arranged at intervals, the upper steel beam 1a in the upper steel tray assembly is set in one-to-one correspondence with the number and position of the lower steel beams in the lower steel tray assembly 5; and The structure and size of the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com