Double-cold source fresh air handling unit

A fresh air unit and dual cold source technology, applied in the field of processing equipment, can solve the problems of small cooling load, harsh wet environment, moldy and spoiled indoor items, etc., to achieve energy-saving operation, moderate fresh air temperature, and avoid indoor humidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

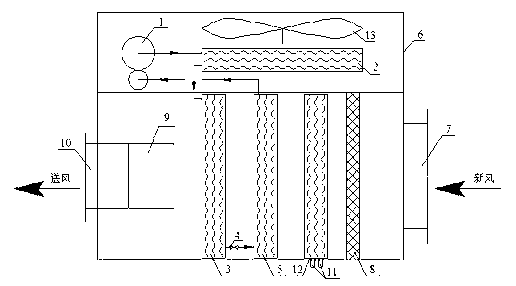

[0015] Such as figure 1 The shown double cold source fresh air unit includes a fresh air unit casing 6, and a compressor 1, a first condenser 2, a second condenser 3, a throttling device 4, an evaporator 5, an inlet Tuyere 7, filter 8, air outlet 10, chilled water supply and return pipe 11 and surface cooler 12. The compressor 1, the first condenser 2, the second condenser 3, the throttling device 4 and the evaporator 5 are sequentially connected through copper pipes to form the self-cooling system of the fresh air unit; the surface cooler 12 is supplied and returned through the chilled water pipe 11 Connect the cold source system of the external centralized air conditioner; the filter 8 is installed at the air inlet 7; superior.

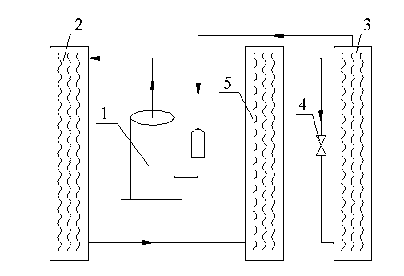

[0016] The flow direction of the refrigerant in the self-cooling source system of the fresh air unit in this embodiment is as follows: figure 2 As shown, the refrigerant enters the first condenser 2 and then the second condenser 3 after being co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com