Cooling water circulation pump system

A cooling water circulation and circulating pump technology, applied in the direction of pumps, pump devices, non-variable-capacity pumps, etc., can solve the problems of large investment in high-power inverter equipment, unfavorable energy saving and consumption reduction, and increase pump energy consumption, and achieve energy saving and reduction. Significant energy consumption, lower power generation costs, and lower maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

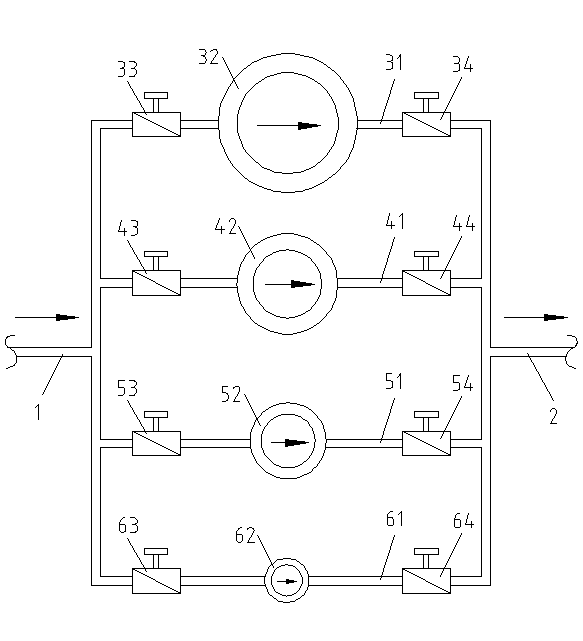

[0021] see figure 1 , the cooling water circulating pump system in this embodiment includes four circulating pumps connected in parallel, and these four circulating pumps are No. 1 circulating pump 32, No. 2 circulating pump 42, No. 3 circulating pump 52 and No. 4 circulating pump 62; Valves are installed at the inlet and outlet of each circulating pump, and the valves at the inlet and outlet are inlet valves and outlet valves respectively, and the valves are all electro-hydraulic butterfly valve structures. Each circulation pump has the same design lift, but has different design flow; each circulation pump is driven by a fixed speed motor, and runs at a constant speed, so that the cooling water circulation pump system has a range from the minimum circulating water flow to the maximum circulating water flow. The step-wise flow adjustment function between them can meet the needs of adjusting the flow of circulating cooling water in different seasons and different working condit...

Embodiment 2

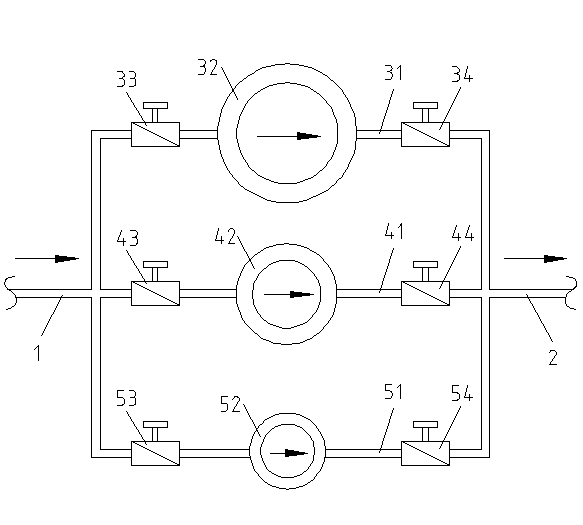

[0032] see figure 2 , the cooling water circulating pump system in the present embodiment includes three circulating pumps connected in parallel, and these three circulating pumps are respectively No. 1 circulating pump 32, No. 2 circulating pump 42 and No. 3 circulating pump 52; Both the inlet and the outlet are equipped with valves, the valves located at the inlet and the outlet are inlet valves and outlet valves respectively, and the valves are all electro-hydraulic butterfly valve structures. Each circulation pump has the same design lift, but has different design flow; each circulation pump is driven by a fixed speed motor, and runs at a constant speed, so that the cooling water circulation pump system has a range from the minimum circulating water flow to the maximum circulating water flow. The step-wise flow adjustment function between them can meet the needs of adjusting the flow of circulating cooling water in different seasons and different working conditions. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com