Stud welding counter

A counter and stud welding machine technology, applied in the direction of counting mechanism/items, instruments, etc., can solve the problems of body-in-white stud rework and repair, large number of welding, multi-welding studs, etc., to achieve large-scale promotion and low cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

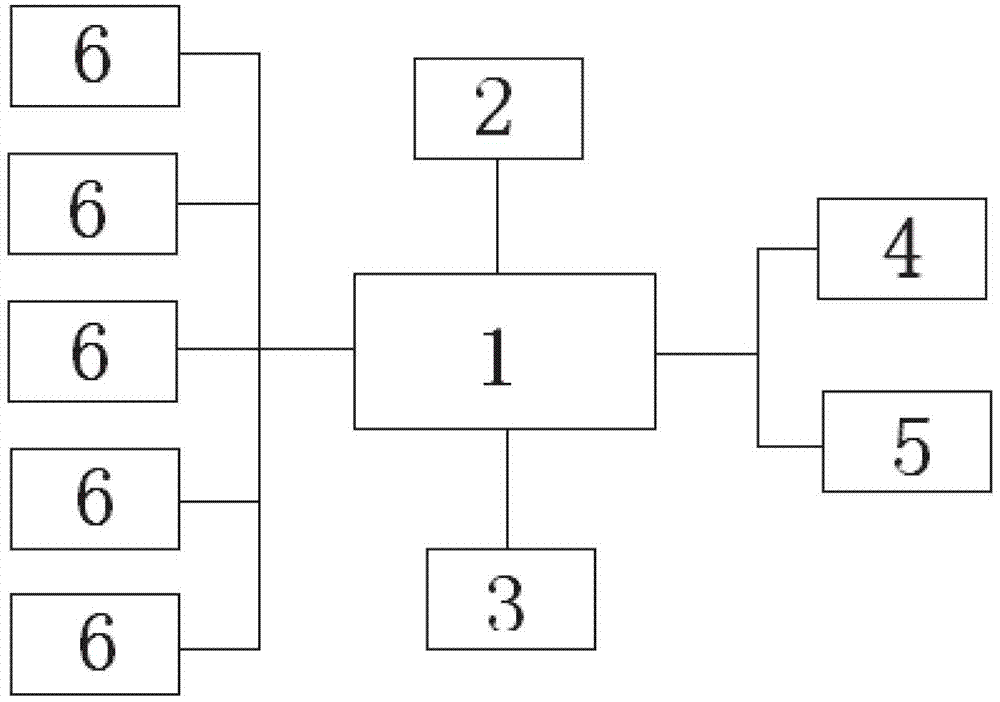

[0014] Such as figure 1 As shown, the present invention is that the counter host 1 receives the welding completion signal delivered by the stud welding machine 6 and calculates the interval delay; the counter host 1 counts the quantity of the completion signal and displays it on the LED digital tube 3. Compare the preset interval time to judge whether the welding is completed, and then compare the welding quantity with the preset quantity to judge whether there is too much welding or missing welding, so as to realize the monitoring of the welding quantity and give an alarm.

[0015] The counter host 1 is connected to the buzzer 4 and the alarm lamp 5 respectively, and gives an audible and visual alarm when there is an error in the welding quantity. The counter host 1 is connected to five stud welding guns 6 at the same time, and monitors the five stud welding guns 6 respectively.

[0016] The counter host 1 is connected with a key unit 2 for inputting the interval time and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com