Production method of thick-electrode device

A production method and electrode technology, which is applied in the manufacture of inductors/transformers/magnets, electrical components, cables/conductors, etc., can solve the problems of increased electrode slurry consumption, sintering cracks, and increased product costs, and reduce DC resistance , the effect of reducing the width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

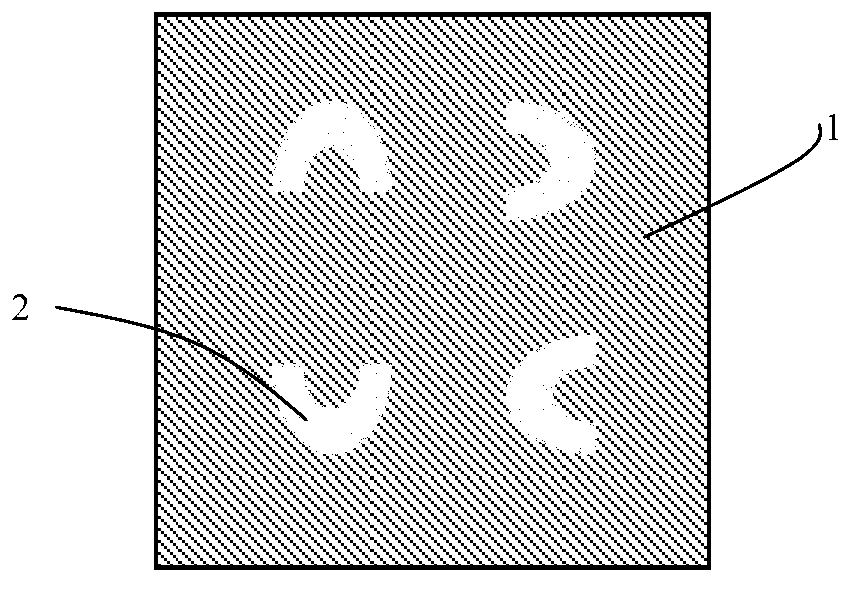

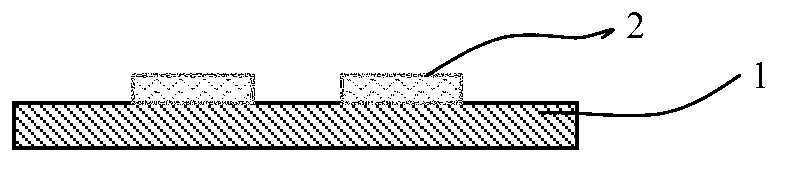

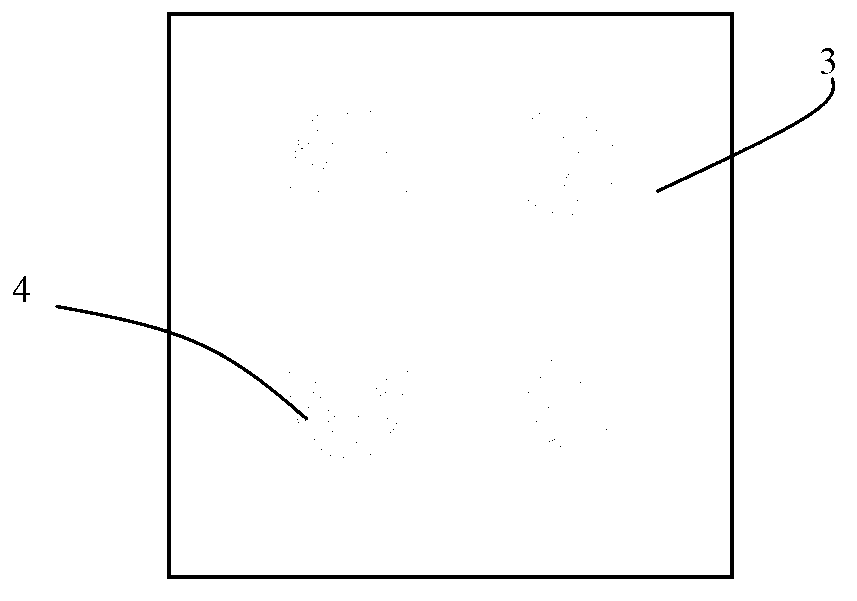

[0044] This embodiment provides a method for manufacturing a thick electrode device, which is carried out according to the above steps, wherein the thickness of the electrode paste 2 printed on the first ceramic substrate 1 and the film 3 with a release function in step 1) is 25 μm; the pressure of the laminator in step 2) is 0.15 tons / square inch, and the temperature is 30°C; the pressure of the laminator in step 3) is 0.15 tons / square inch, and the temperature is 30°C, and the third ceramic substrate is formed After 7 and electrode slurry 6, the thickness of the electrode is 36 μm at this time, that is, a complete device structure is formed; the deglue curve in step 4) is: firstly heat up to 200°C after 20 hours, then heat up to 400°C, keep warm 10 hours, and finally cool down naturally; the sintering curve in step 5) is: firstly, the temperature is raised to 700°C in 10 hours, then to 900°C, kept for 5 hours, and the temperature is naturally lowered to obtain the thick elect...

Embodiment 2

[0046] This embodiment provides a method for manufacturing a thick electrode device, which is carried out according to the above steps, wherein the thickness of the electrode paste 2 printed on the first ceramic substrate 1 and the film 3 with a release function in step 1) is 30 μm; the pressure of the laminator in step 2) is 0.2 tons / square inch, and the temperature is 35°C; the pressure of the laminator in step 3) is 0.2 tons / square inch, and the temperature is 35°C, and the third ceramic substrate is formed 7 and electrode paste 6, the thickness of the electrode at this time is 41 μm, and the third ceramic substrate 7 is printed on the third ceramic substrate 7 according to the required electrode pattern stacking sequence and the steps 1) to 3) are laminated 5 times and the ceramic substrate is formed. A complete device structure; the deglue curve in step 4) is: first heat up to 300°C for 25 hours, then heat up to 350°C, keep warm for 20 hours, and cool down naturally; the s...

Embodiment 3

[0048]This embodiment provides a method for manufacturing a thick electrode device, which is carried out according to the above steps, wherein the thickness of the electrode paste 2 printed on the first ceramic substrate 1 and the film 3 with a release function in step 1) is 28 μm; the pressure of the lamination machine in step 2) is 0.25 tons / square inch, and the temperature is 25°C; the pressure of the lamination machine in step 3) is 0.25 tons / square inch, and the temperature is 25°C, and the third ceramic substrate is formed 7 and electrode paste 6, the thickness of the electrode at this time is 38 μm, and the third ceramic substrate 7 is printed on the third ceramic substrate 7 in accordance with the required electrode pattern stacking sequence for 9 times and the laminated ceramic substrate is formed. A complete device structure; the deglue curve in step 4) is: firstly, the temperature is raised from room temperature to 180°C for 22 hours, then the temperature is raised t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com