Manufacturing process for copper-based printed circuit board with embedded circuits

A printed circuit board and manufacturing process technology, which is applied in the direction of assembling printed circuits with electrical components, can solve problems such as short life, poor stability, and low heat dissipation efficiency, and achieve the effects of prolonging service life, avoiding limited life, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

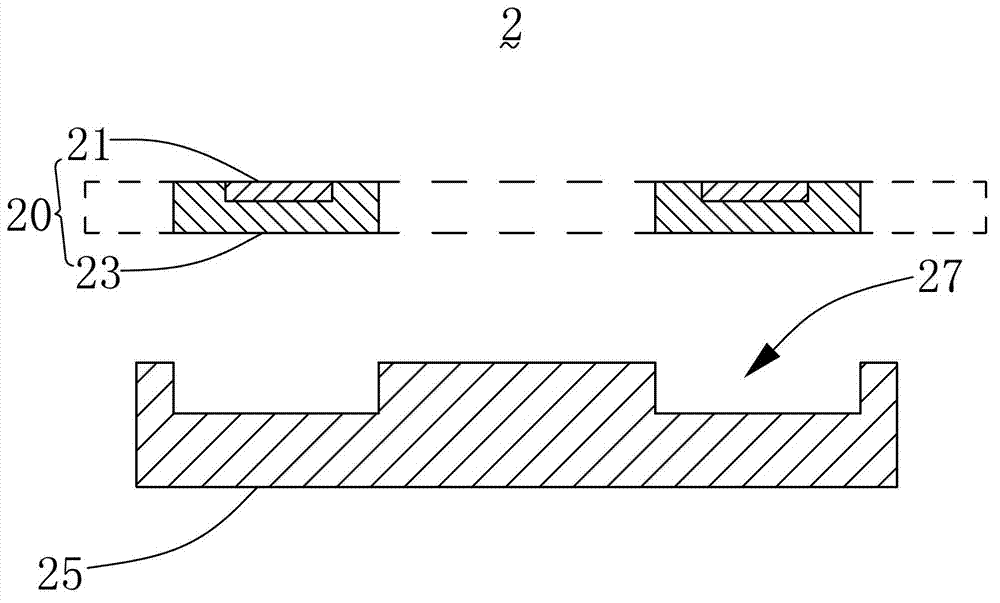

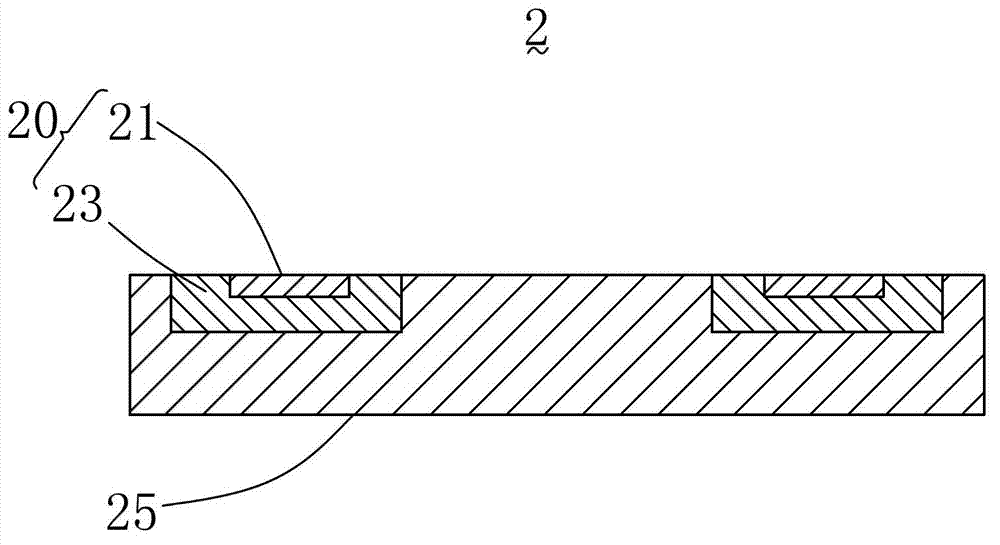

[0022] Figure 2 to Figure 4 Disclosed is a preferred embodiment of the printed circuit board structure and manufacturing process of copper-based embedded circuits of the present invention.

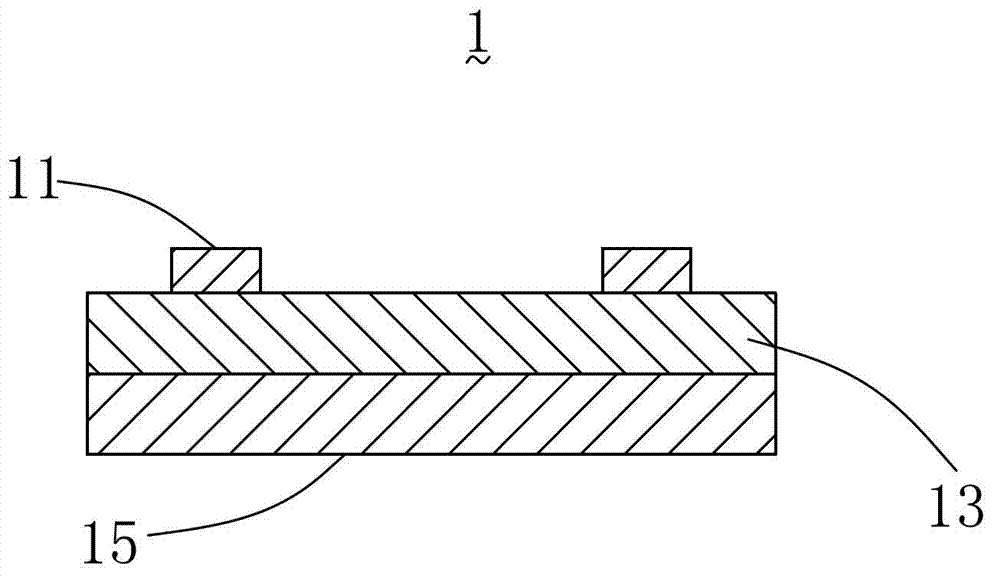

[0023] Please also see figure 2 and image 3 . in figure 2 It is an exploded schematic diagram of the manufacturing process structure of a copper-based printed circuit board with embedded circuits in the present invention. image 3 yes figure 2 A schematic diagram of the assembly of a printed circuit board manufacturing process structure with embedded circuits in a copper base is shown. The copper-based printed circuit board 2 includes a copper-clad laminate 20 with copper removed from the bottom, a heat sink 25 and a plurality of electronic components (not shown) disposed on the surface of the substrate 20 .

[0024] The copper clad laminate 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com