Method for preparing bean curd by means of bean curd machine and bean curd machine

A tofu machine and tofu technology, applied in the field of tofu machine making tofu and tofu machine, can solve the problems of easy overflow, overcooking and undercooking of tofu, and achieve the effects of improving reliability, solving scorching and reducing assembly steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

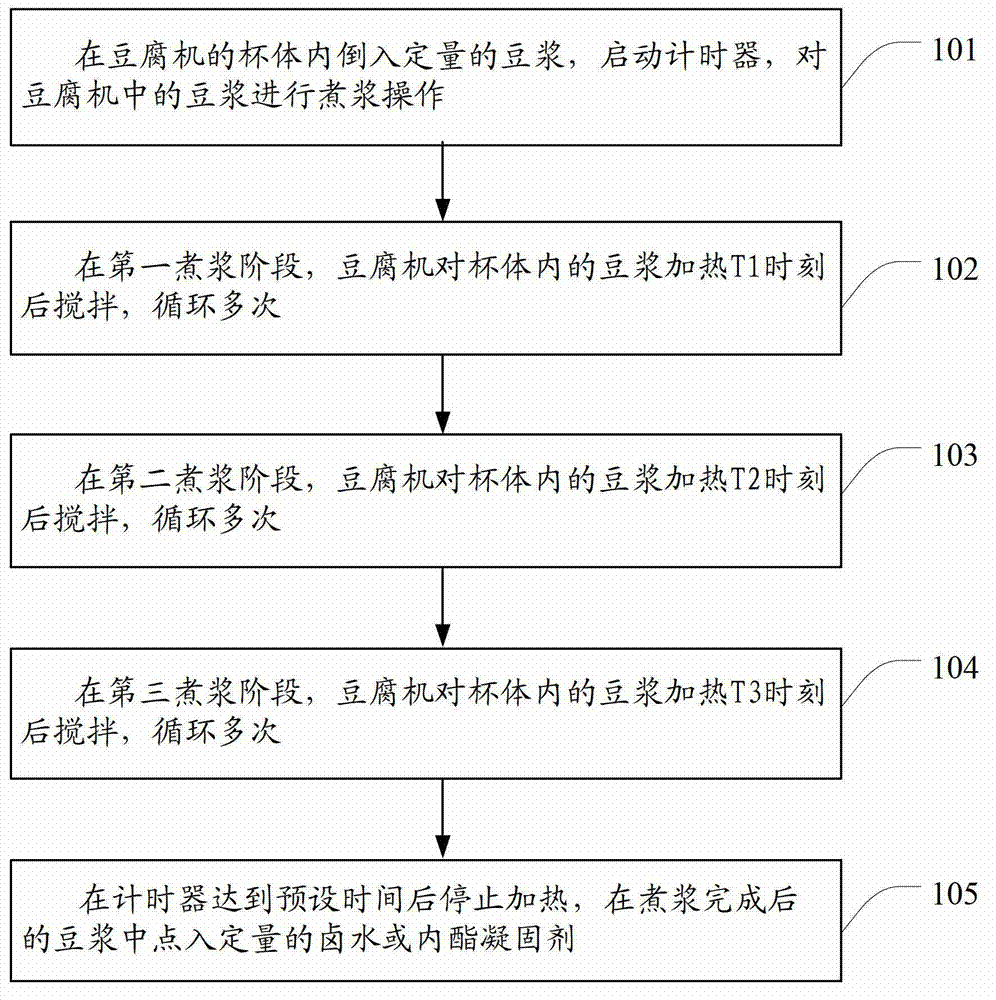

[0057] figure 1 It is a flow chart of making tofu by a kind of tofu machine in the present invention; as figure 1 as shown,

[0058] Step 101, pour a certain amount of soybean milk into the cup of the tofu machine, start a timer, and perform the operation of boiling the soybean milk in the tofu machine.

[0059] Step 102, in the first stage of boiling milk, heat the soymilk in the tofu machine for T1 and then stir it, and cycle for several times.

[0060] Step 103, in the second milk cooking stage, heat the soymilk in the tofu machine for T2 and then stir it, and cycle for several times.

[0061]Step 104, in the third milk cooking stage, heat the soymilk in the tofu machine for T3 and then stir it, and cycle for several times.

[0062] Step 105, stop heating after the timer reaches the preset time, and pour a certain amount of brine or internal fat coagulant into the soybean milk after the boiling is completed.

[0063] In step 101, a certain amount of soybean milk is pour...

Embodiment 2

[0069] This embodiment is the same as embodiment one except the following features

[0070] In this embodiment, the tofu machine is used to grind the soybean material into soybean milk. Specifically, before pouring a certain amount of soybean milk into the cup of the tofu machine, put the soybean material and water into the cup of the tofu machine in a certain proportion; at normal temperature, start the motor for 25-35 seconds and stop for 4-8 seconds, Cycle 8-12 times, grind the soy material into soy milk and filter out the bean dregs.

[0071] Preferably, at normal temperature, start the motor for 30 seconds and stop for 6 seconds, and cycle 10 times to grind the soybean material into soybean milk. Then pour the soymilk from which the bean dregs have been filtered out into the cup of the tofu machine. Among them, the advantage of grinding soybean milk at room temperature is that it can prevent protein denaturation in soybean milk caused by heating. In addition, low-conce...

Embodiment 4

[0098] This embodiment is the same as embodiment three except the following features

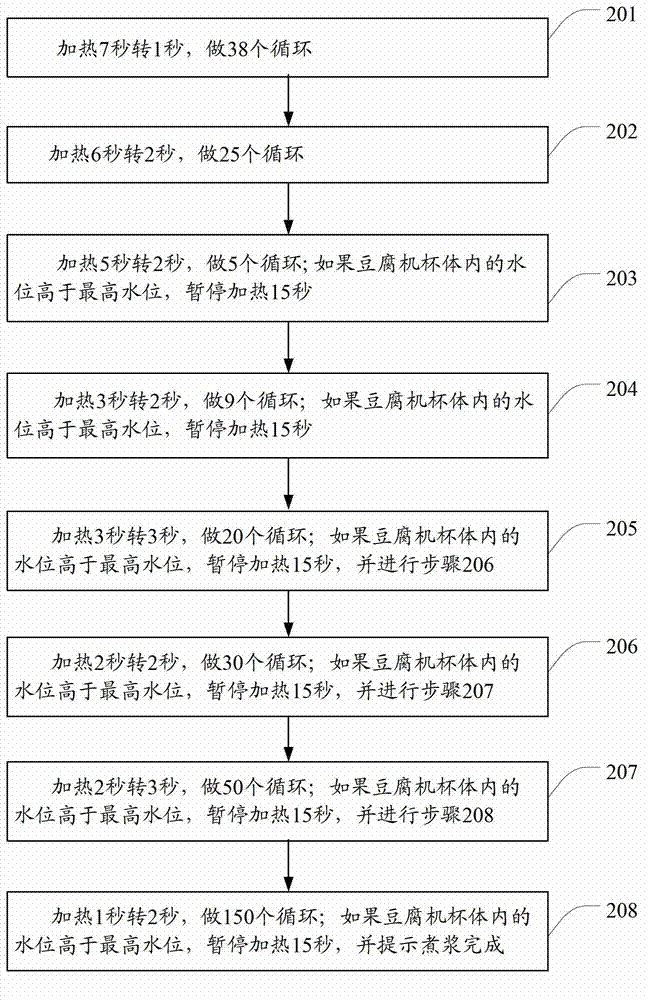

[0099] In this embodiment, in the third pulp cooking stage, when the anti-overflow probe on the tofu machine detects a corresponding signal, the heating is suspended for 10-20 seconds; wherein, after the heating process is suspended, the next sub-stage is carried out, and the anti-overflow at the same time The probe performs a detection every 6 seconds; when a relevant signal is detected, the heating operation is stopped; when the number of detections exceeds 5 times, the heating operation of the current sub-stage continues.

[0100] Specifically, after the heating process is suspended, while the next sub-stage is being performed, the anti-overflow probe of the tofu machine detects the water level in the cup every 6 seconds. If the water level in the cup is not detected or the foam touches the anti-spill probe, continue heating. If it is detected that the water level in the cup or the foam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com