Flue gas dry desulfurization device

A dry desulfurization and flue gas technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of flue blockage, wall sticking and scaling, ash removal, etc., to reduce operating costs, Enhance adaptability and reduce the effect of water spray

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

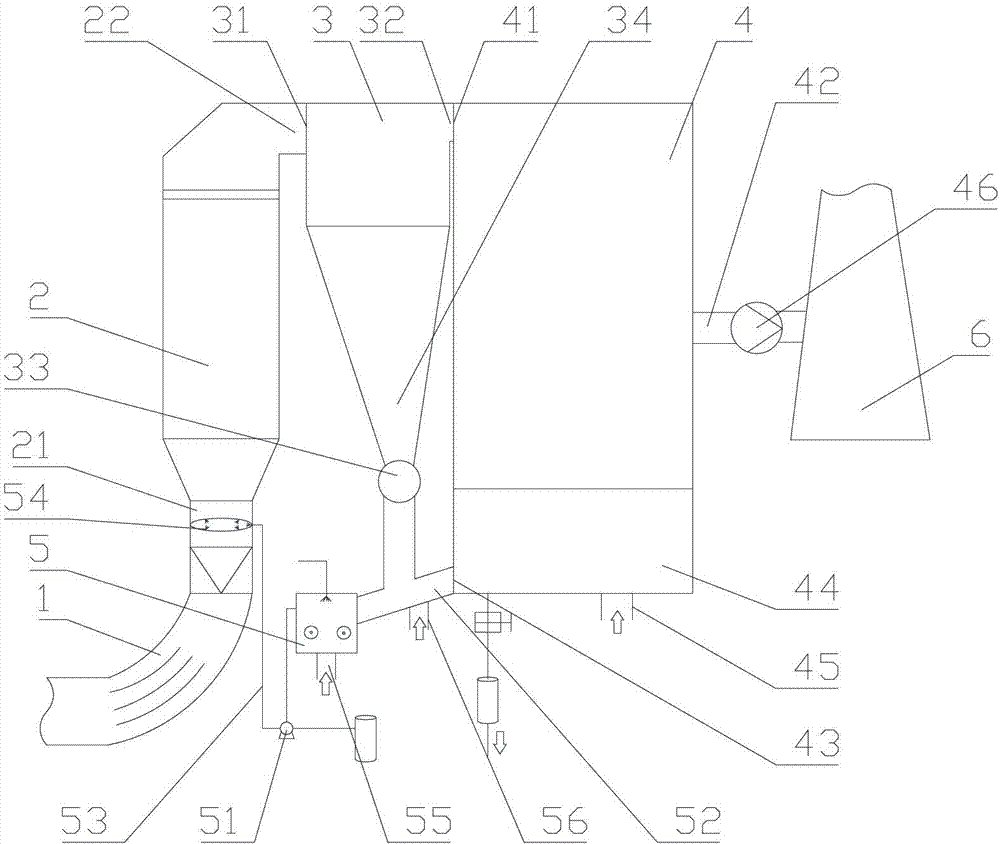

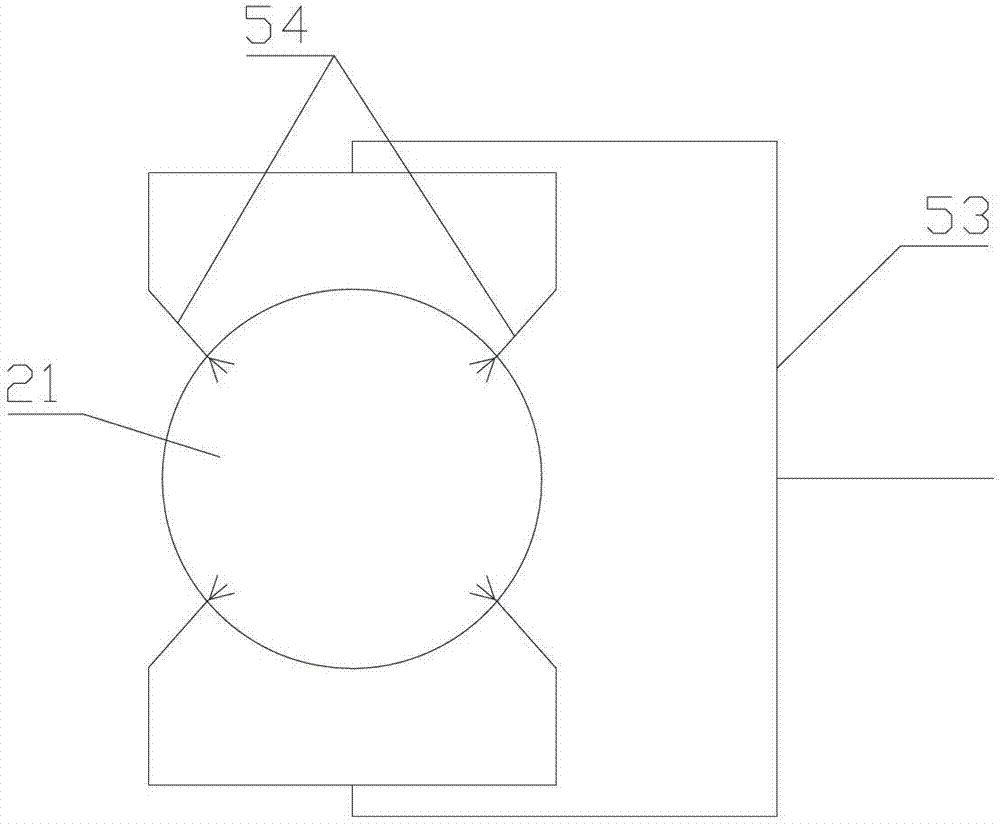

[0018] Such as figure 1 with 2 Shown is an embodiment of the present invention, a flue gas dry desulfurization device, comprising a smoke inlet pipe 1, a desulfurization reactor 2, a settling chamber 3, a dust collector 4 and a desulfurizer recycling device, the smoke inlet pipe and The inlet 21 of the desulfurization reactor is communicated, and the outlet 22 of the desulfurization reactor is communicated with the inlet 31 of the settling chamber, and the first flue gas outlet 32 and the first desulfurizing agent outlet for large particle desulfurizing agent to flow out are provided on the settling chamber 33. The first flue gas outlet communicates with the inlet 41 of the dust collector, and the dust collector is provided with a second flue gas outlet 42 communicating with the outside atmosphere and a second desulfurizing agent outlet 43 for outputting desulfurization circulating ash, so The first desulfurizing agent outlet and the second desulfurizing agent outlet are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com