Cold-bending forming machine for vehicle-mounted high-intensity arc corrugated plate

A cold-formed, high-strength technology, applied in the direction of forming tools, feeding devices, positioning devices, etc., can solve the problems of installation foundation, lifting equipment requirements, high temperature, dust requirements, hydraulic oil leakage, etc., and meet the requirements Low height, accurate cold-formed size, and not easy to rebound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

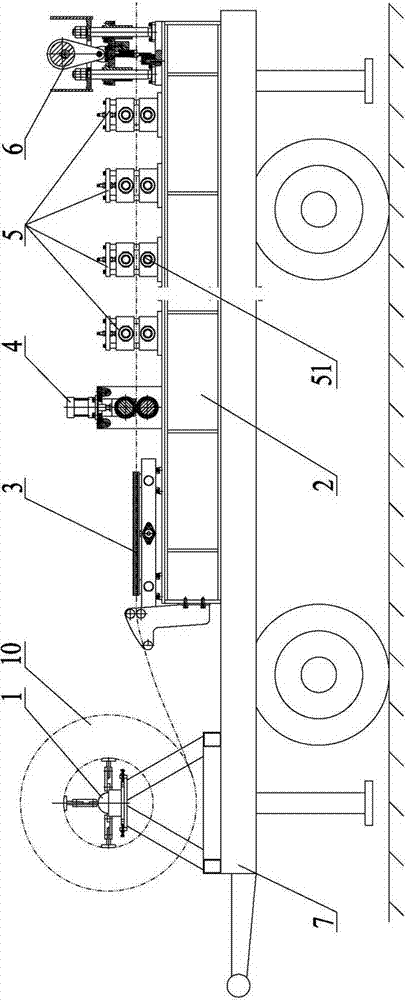

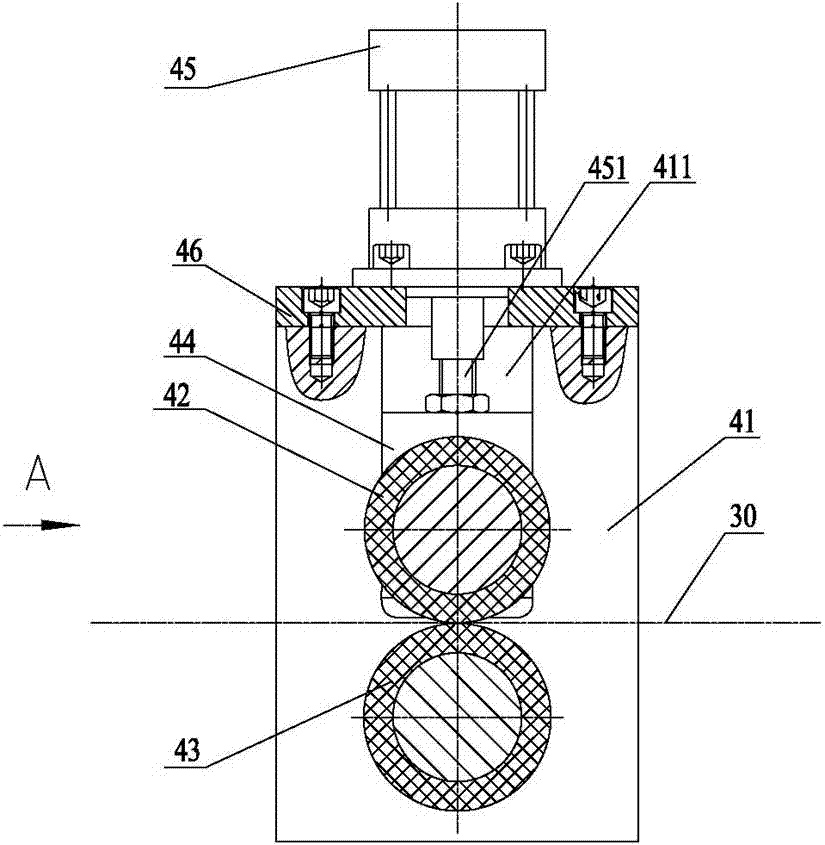

[0029] Please refer to the attached figure 1 To attach Figure 9 As shown, the present invention is a vehicle-mounted high-strength arc corrugated plate cold bending forming machine, which consists of an uncoiler 1, a base 2, a guiding device 3, a plate feeding device 4, a cold forming roll group 5, a cutting device 6 and Several parts such as trailer 7 are formed.

[0030] Wherein, the shown uncoiler 1 and the base 2 are respectively arranged on the trailer 7 . This trailer 7 can also be a flat semi-trailer for a flat trailer. The shown guiding device 3 , plate feeding device 4 , cold-bending forming roll group 5 and cutting device 6 are installed on the base 2 in sequence.

[0031] The uncoiler 1 is used to uncoil the tubular coil material 10, which includes a tensioning mandrel 11 and two supporting frames 12, and the tensioning mandrel 11 and the supporting frames 12 are of split structure. Wherein, the tensioning mandrel 11 is a mechanical structure without hydraulic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com