Round working table driving and sliding base feed driving device

A technology of feed drive and worktable, applied in the direction of drive device, positioning device, feeding device, etc., can solve the problems of large foreign exchange purchase and low processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The circular table driving and sliding seat feeding driving device of the present invention will be further described in detail through specific embodiments.

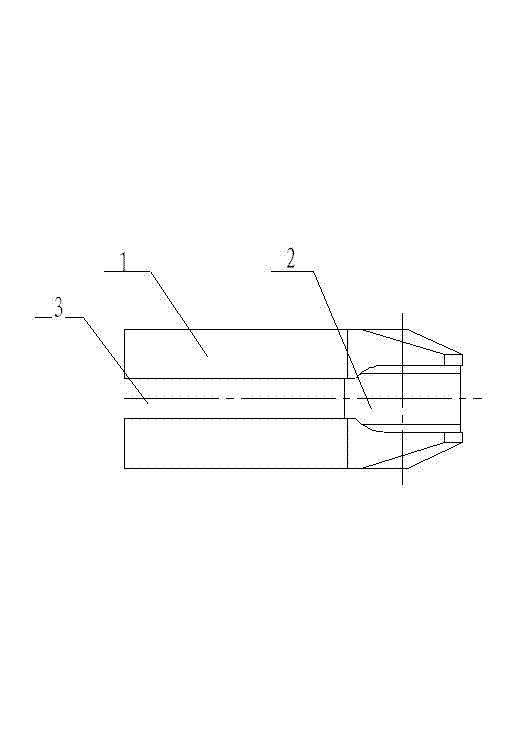

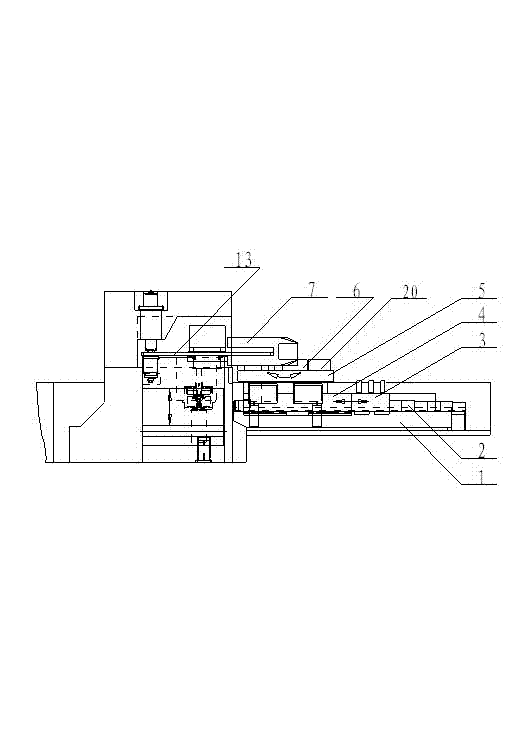

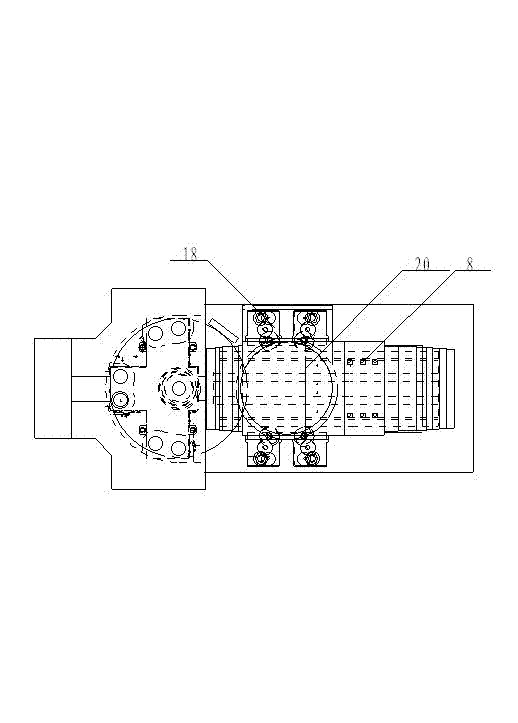

[0020] Such as figure 2 , image 3 , Figure 4 As shown, the overall structural layout design of the CNC crank turning and milling machine is divided into two major working parts: the first working part is the milling circular cutter spindle drive and feed drive combination device; the second working part is the circular worktable workpiece clamping support and sliding seat Feed drive combination.

[0021] The working part of the milling circular cutterhead spindle drive and feed drive combination device, and the work part of the circular worktable workpiece clamping support and slide seat feed drive combination device adopt a series installation combination layout. The workpiece clamping support of the round table and the working part of the sliding seat feed drive combination device are installed at the fro...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap