Tin soldering machine abnormal tin-discharging monitoring mechanism and method, tin-discharging device and tin soldering machine

A technology of abnormal monitoring and soldering machine, applied in the direction of tin feeding device, auxiliary device, welding equipment, etc., can solve the problems of high cost, affecting welding accuracy, troublesome installation and debugging, etc., and achieve low cost, good real-time performance and high sensitivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is described in further detail now in conjunction with accompanying drawing.

[0035] first embodiment

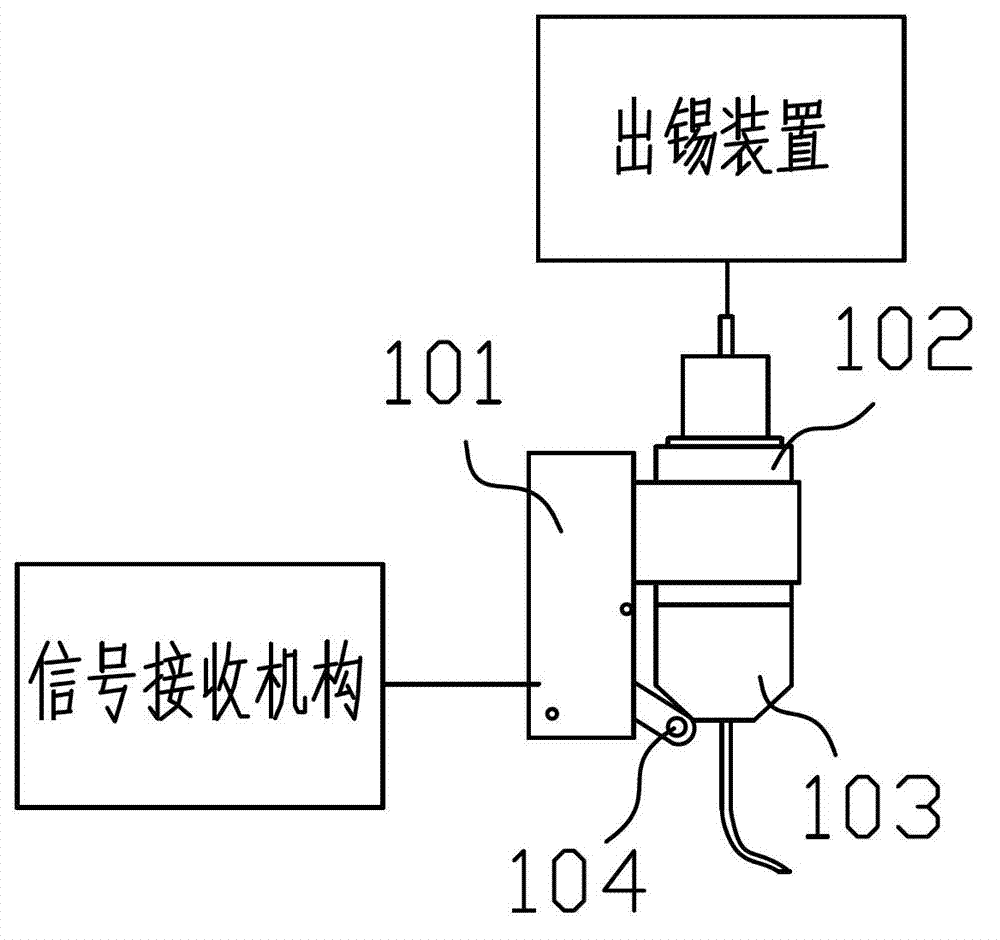

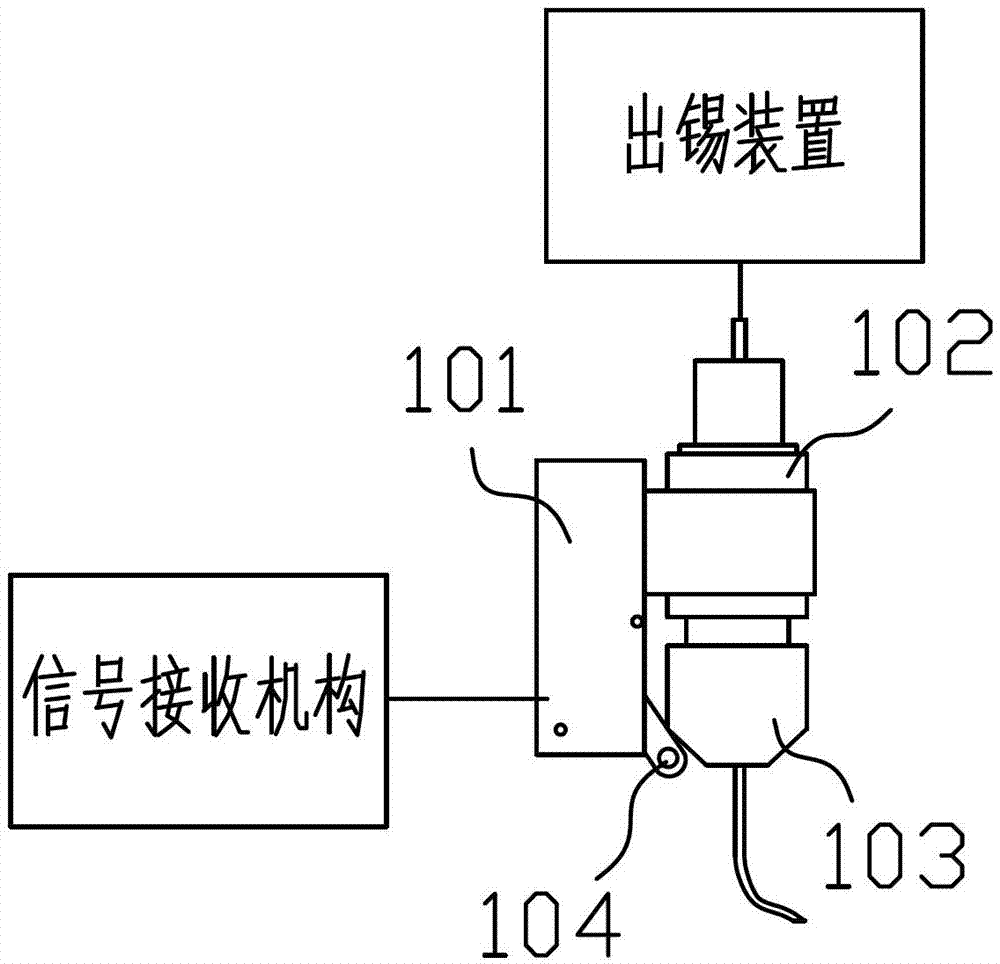

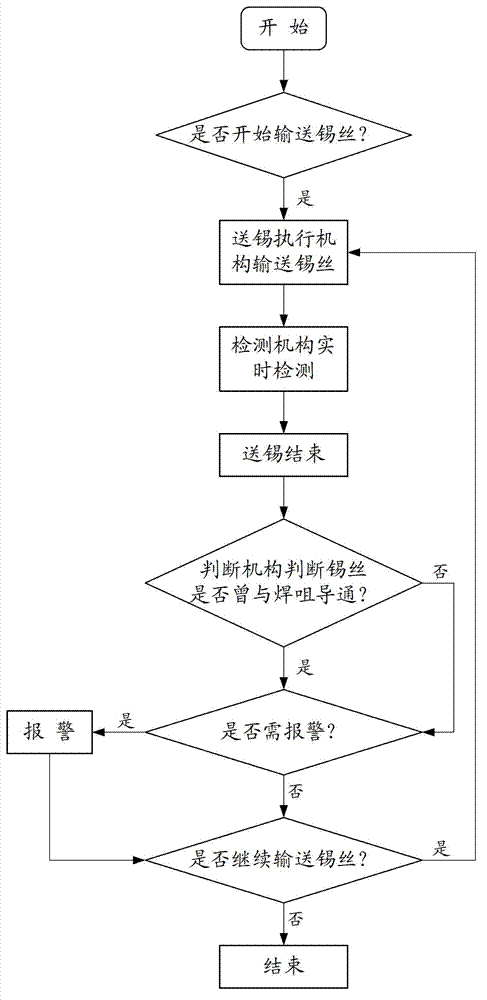

[0036] Such as Figure 4-6 As shown, the structure schematic diagram of the first embodiment of the soldering machine of the present invention and the principle diagram of abnormal tin discharge monitoring. It includes a soldering nozzle 3 and a tin discharging device 1 for delivering tin wire 2 to the soldering nozzle 3, and the tin discharging device 1 includes a soldering machine tin-discharging abnormality monitoring mechanism and a tin-feeding actuator.

[0037] The tin abnormality monitoring mechanism of the soldering machine has an insulation mechanism for insulating the tin wire 2 from the solder tip 3 and a signal detection and judgment mechanism for detecting whether the tin wire 2 is connected to the solder tip 3. The signal detection and judgment mechanism includes Whether the tin wire 2 is connected to the detection mechanism of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com