Wafer cutting method

A cutting method and a wafer technology, which are applied in the fields of electrical components, fine working devices, semiconductor/solid-state device manufacturing, etc., can solve the problems that the bonded wafer 100 cannot be firmly fixed and affect the cutting accuracy, etc., to achieve The effect of improving cutting stability and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the invention will now be described in detail by way of example depicted in the accompanying drawings. However, it is not intended to limit these embodiments to the implementations described below, and the implementations herein are provided so that readers can easily and completely understand the scope and spirit of the present invention. In the illustrations, the size and thickness of some elements and structures are exaggerated for clarity.

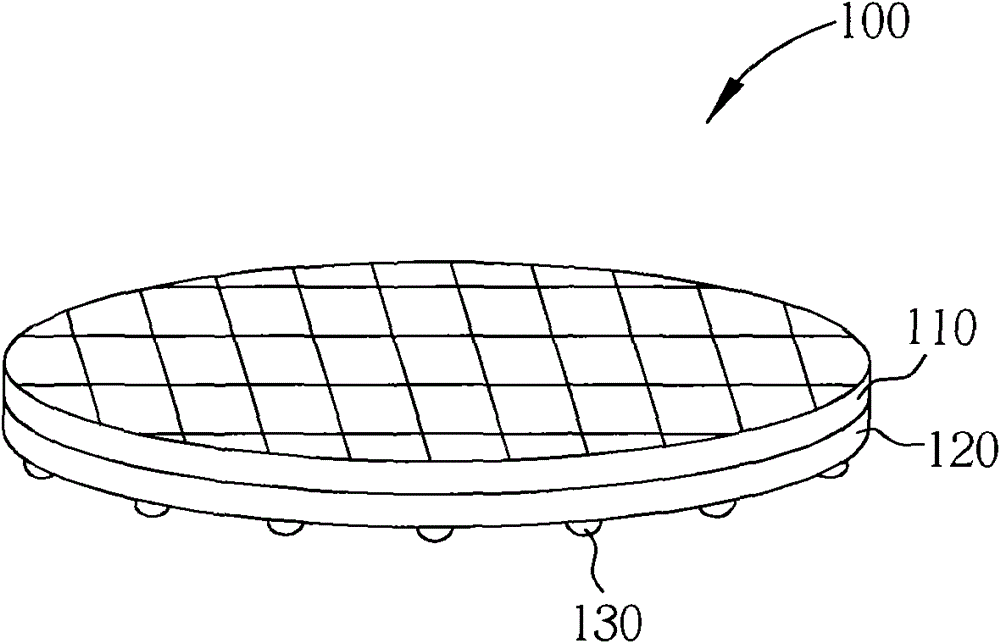

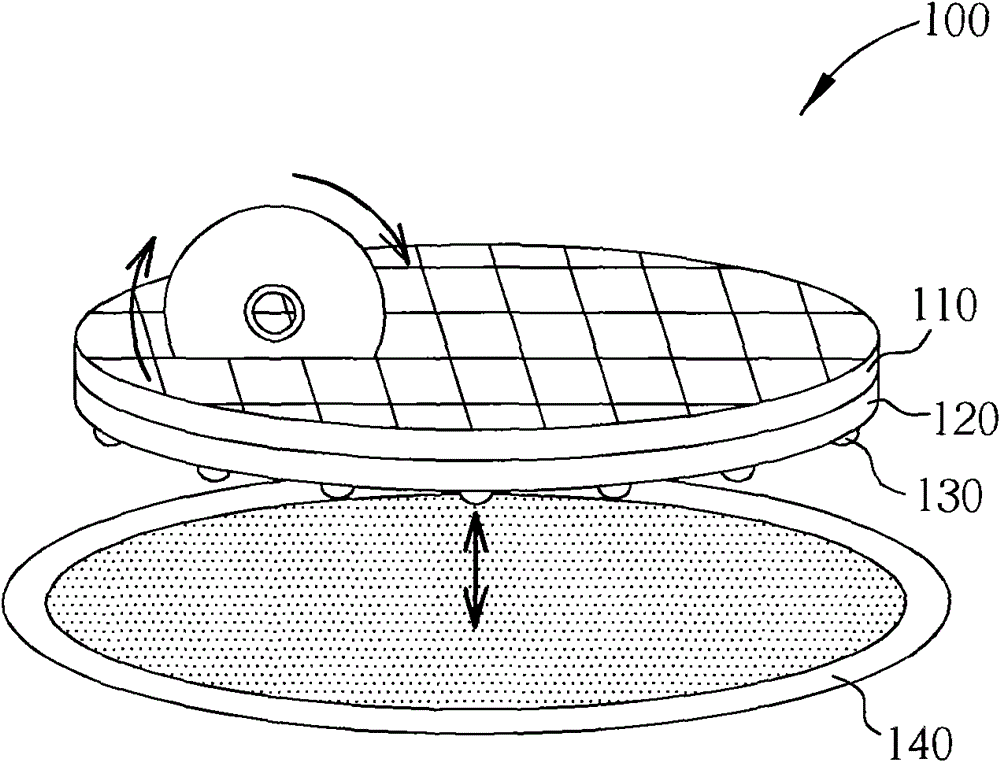

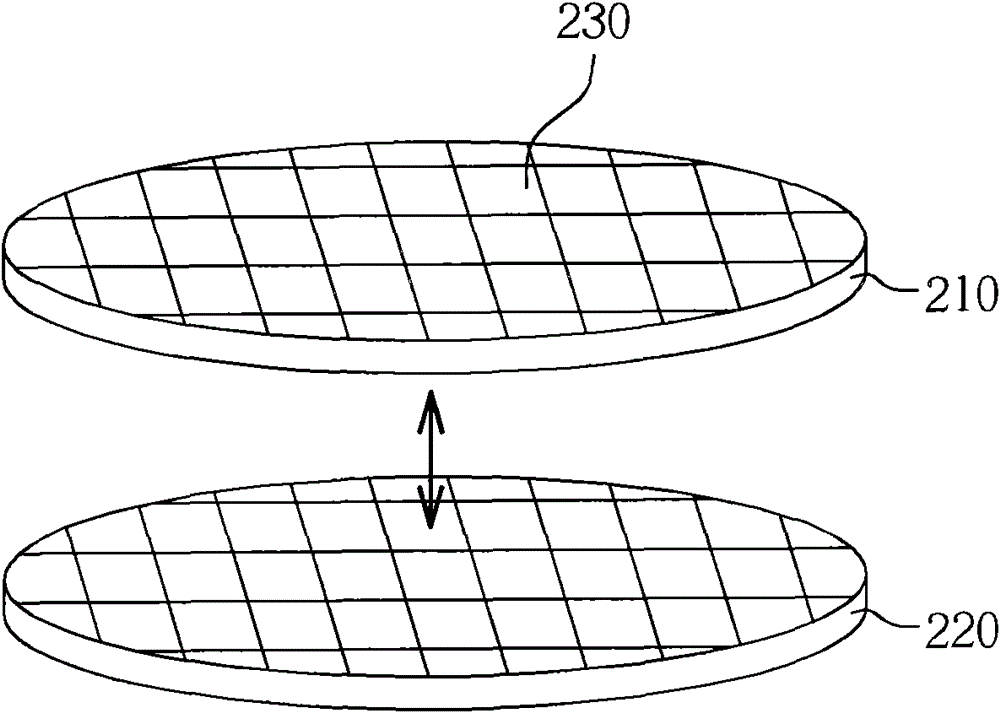

[0034] Please refer to Figure 3 to Figure 11 , which sequentially depict the steps of the wafer cutting method of the present invention. First please also refer to image 3 and Figure 4 , which depicts a schematic diagram of the wafer-to-wafer bonding step in the flow of the wafer dicing method according to the present invention. The object of the wafer dicing method of the present invention is mainly a single wafer or a structure formed by bonding multiple wafers, which is generally referred to as a bonded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com