cutting device

A cutting device and cutting tool technology, applied in glass cutting devices, fine working devices, manufacturing tools, etc., can solve the problems of glass sheet peeling, glass plate cracks, weakening of the cracking effect, etc., to achieve accurate and stable cutting, The effect of preventing the occurrence of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

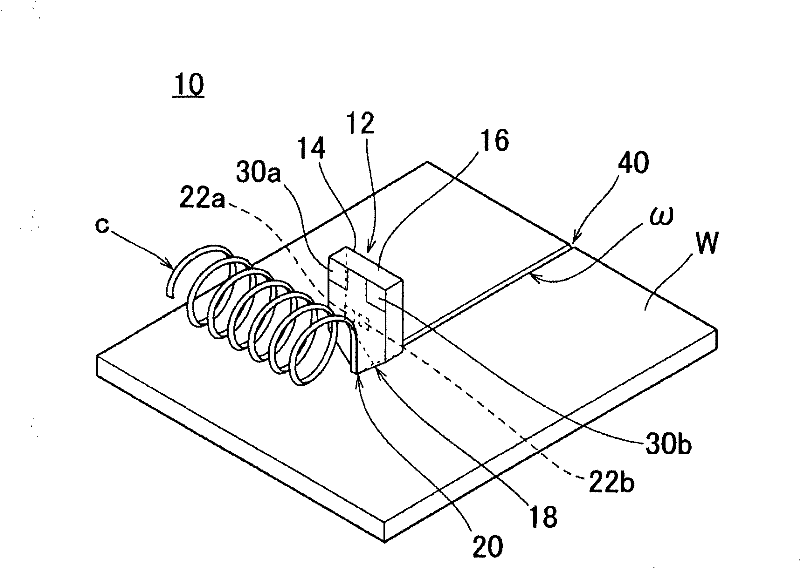

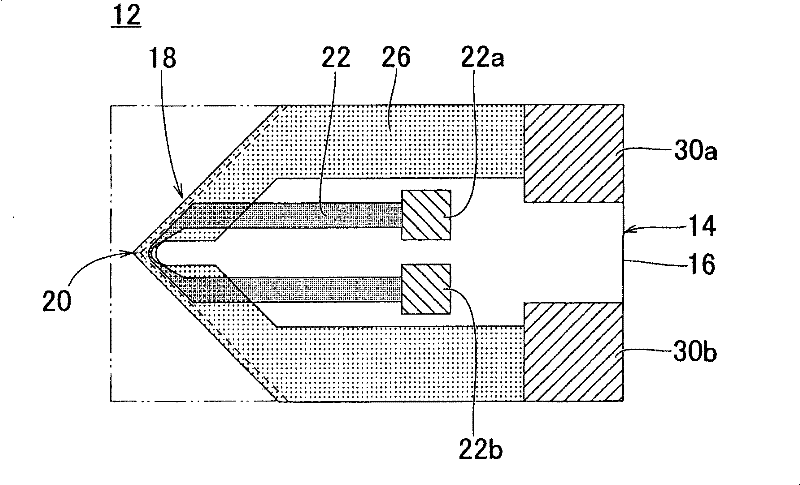

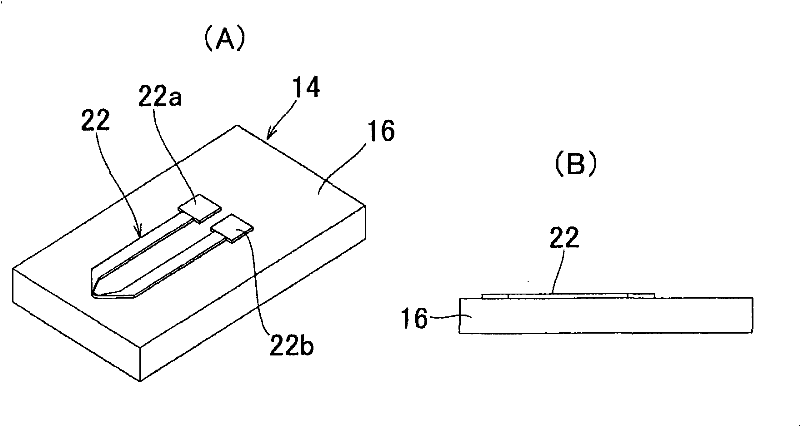

[0082] figure 1 It is a perspective view of main parts showing an example of an embodiment of the cutting device of the present invention, figure 2 for illustrative purposes only figure 1 A plan view of an example of the cutting tool of the embodiment. The cutting device of the present invention is suitable for cutting brittle materials such as optical glass, quartz glass and other glass, ceramics, silicon crystal (silicon), semiconductor materials, etc. A preferable cutting device 10 such as cutting a glass plate in the panel manufacturing process of a display will be described.

[0083] The cutting device 10 includes a cutting tool 12 . For example figure 1 As shown, the cutting tool 12 is disposed so as to be in contact with a predetermined cutting portion ω (referred to as “cutting portion ω” in a narrow sense) of a workpiece (processed object) such as a rectangular glass plate W. Roughly speaking, the cutting tool 10 speeds up the glass sheet W to a high temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com