Turning and guide device for square billets

A technology of guide and guide rails, which is used in the position control of the conveying process of the roller table, before the billet is rolled into the furnace, it can solve the problems of flying out of the roller table, deviation, large deflection, etc., saving time and work efficiency. High, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

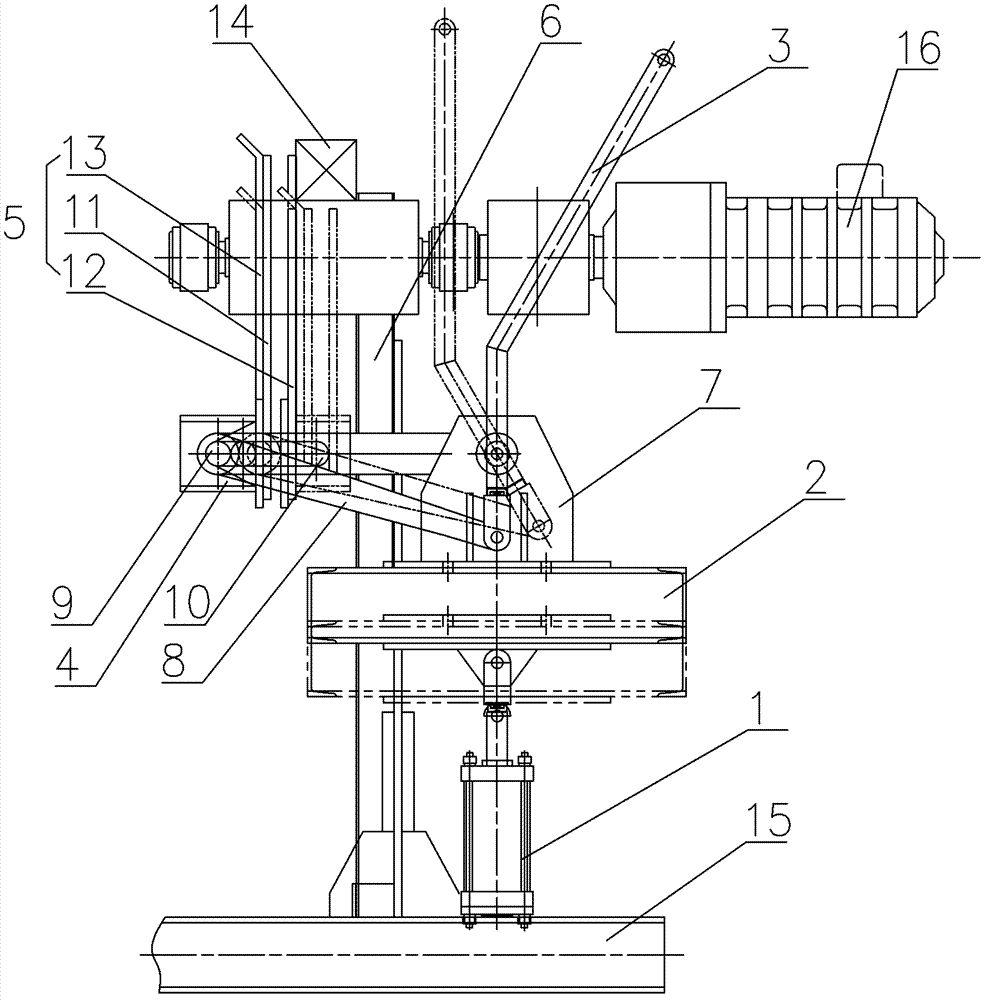

[0015] See figure 1 , is a structural diagram of an embodiment of a billet turning and guiding device of the present invention, including a lifting cylinder 1, a lifting seat 2, an operating lever 3, a guide rail 4, a movable baffle 5 and a fixed baffle 6, and the lifting cylinder 1 is vertically arranged on On the base 15, the end of the piston rod of the lifting cylinder 1 is connected to the center of the bottom of the lifting seat 2, the top of the lifting seat 2 is centered with a hinged seat 7, and the fixed baffle 6 is located on one side of the hinged seat 7 and connected with the base 15. The lower part of 3 is hinged with the hinge seat 7, the lower end of the operating lever 3 is hinged with one end of the swing rod 8, the other end of the swing rod 8 is provided with a slider 9, the guide rail 4 is connected with the hinge seat 7, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com