Tower type crane and cab thereof

A tower crane and driver's cab technology, which is applied to cranes, load hanging components, transportation and packaging, etc., can solve the problems of difficult for drivers to see the construction surface accurately, long distances, and unfavorable operation by drivers, and achieves simple structure, Easy operation and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

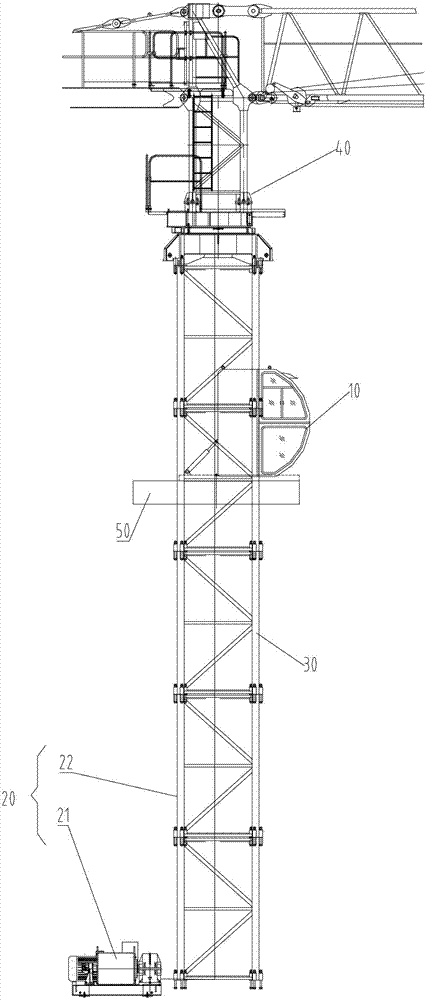

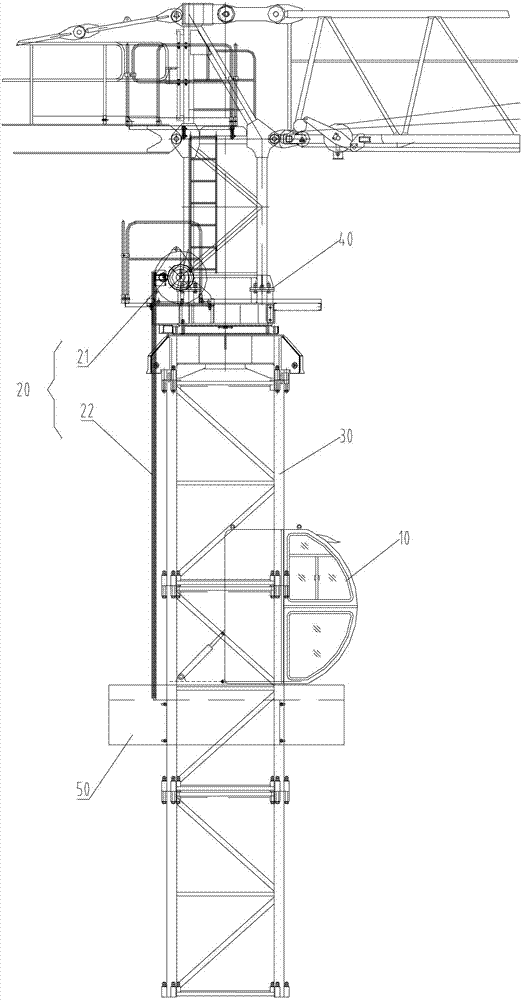

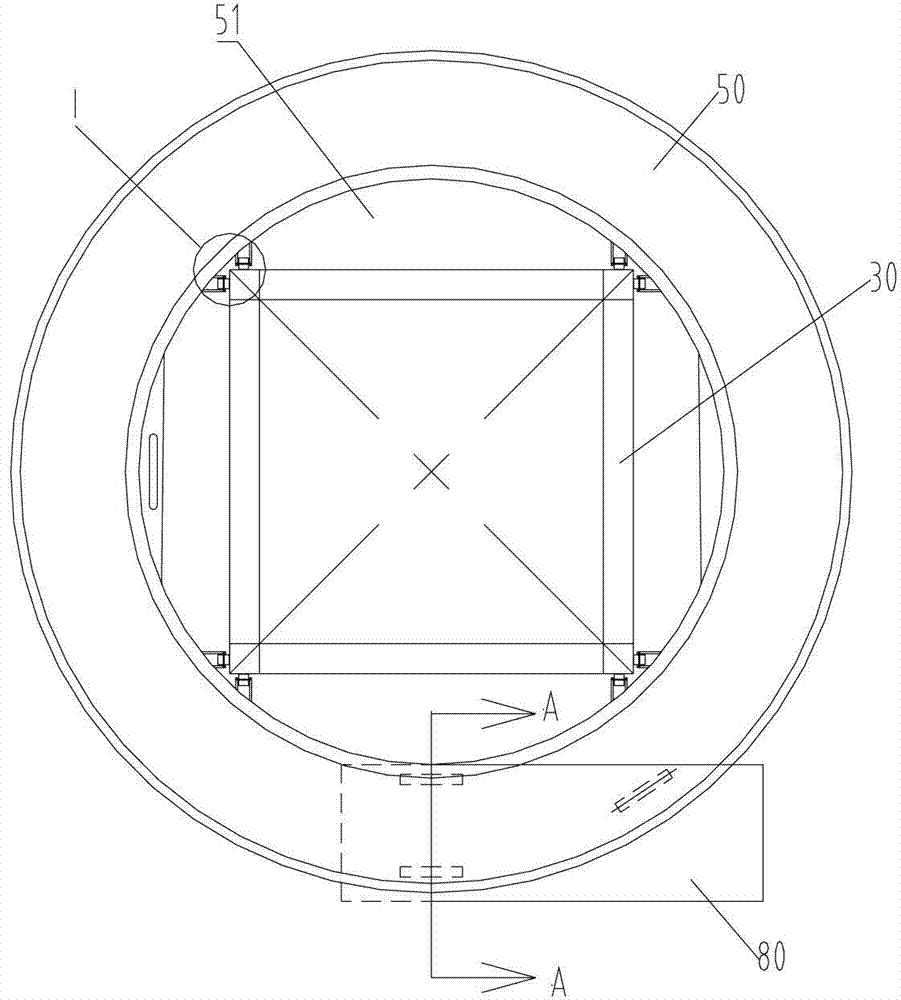

[0034] As a first aspect of the present invention, a driver's cab of a tower crane is provided. Such as figure 1 and figure 2 As shown, the driver's cab includes: an operation control room 10; a lifting device 20, which is connected to the operation control room 10 and drives the operation control room 10 to reciprocate along the extension direction of the tower body 30 of the tower crane to adjust The height of the operation control room 10.

[0035] During work, the height of the operation control room 10 can be adjusted through the hoisting device 20, so that the height of the operation control room 10 is consistent with the height of the construction surface. In this way, the driver can accurately see the situation of the construction surfac...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap